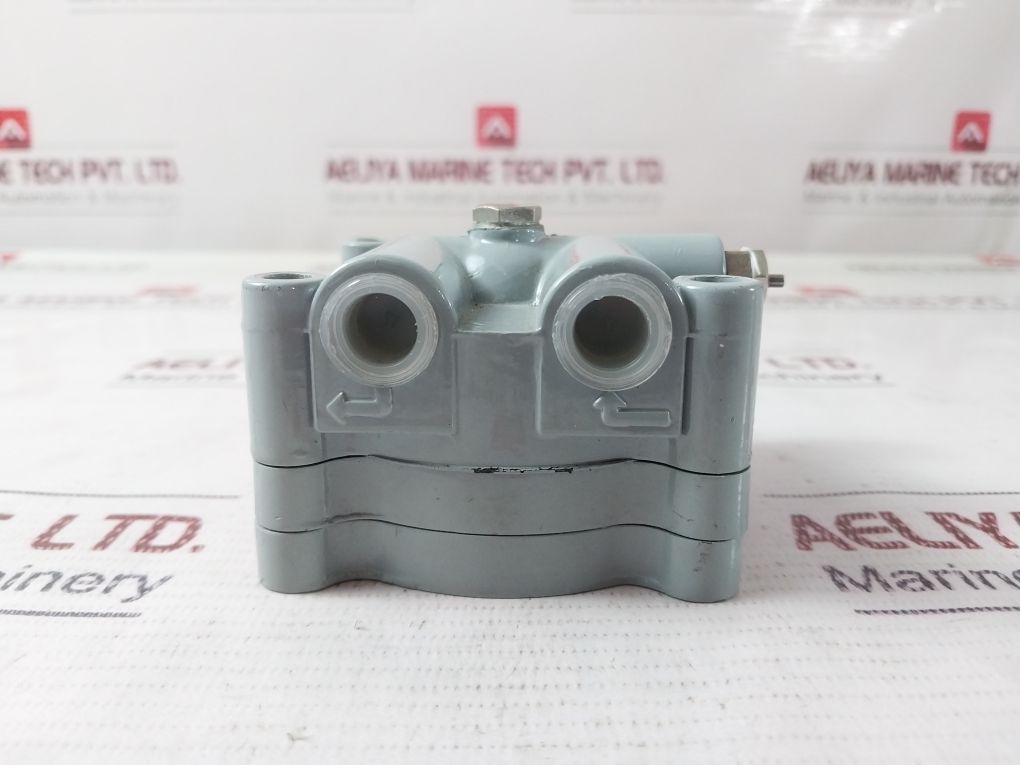

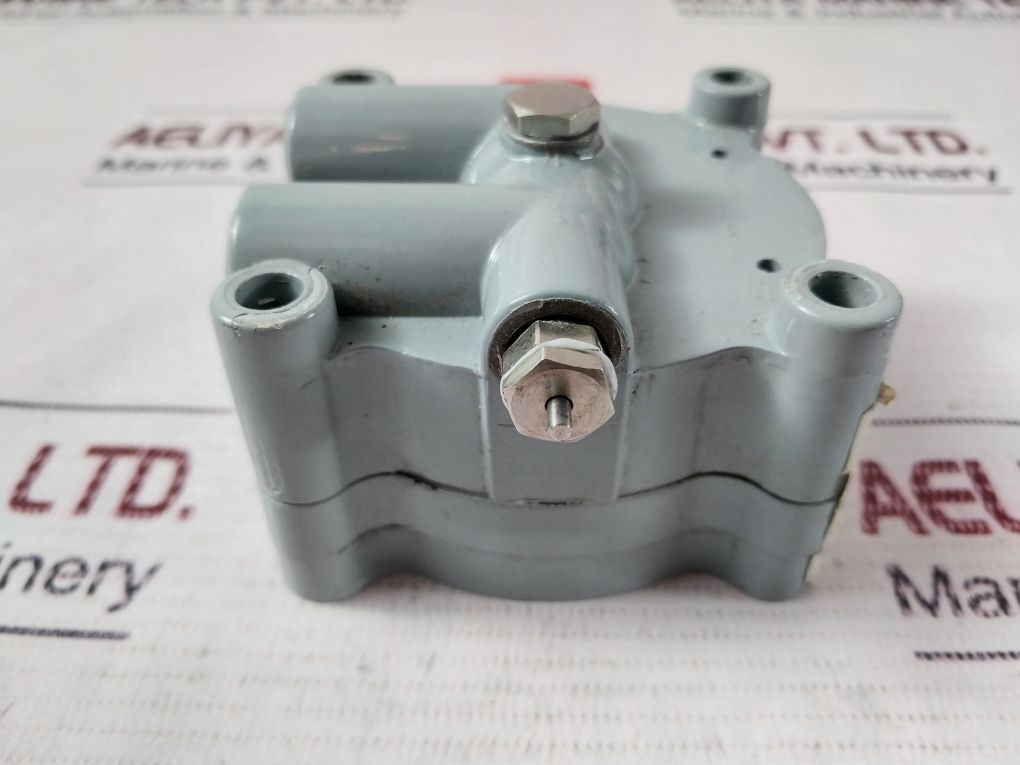

Masoneilan 8013-258 Control Valve

Masoneilan

571.05.52.020

Relay Complete

Model: 8013-258

Weight : 430 Gm

Ref No(S) : 75448

Masoneilan 8013-258 Control Valve

Out of stock

| Brand | |

|---|---|

| Condition | New without box |

| Qty Type | PCS |

| Weight | 430 grams |

- Free Shipping on Order above $100

- 30 Days Warranty

- Fast Shipping via DHL

| Brand | |

|---|---|

| Condition | New without box |

| Qty Type | PCS |

| Weight | 430 grams |

Be the first to review “Masoneilan 8013-258 Control Valve” Cancel reply

Reviews

There are no reviews yet.