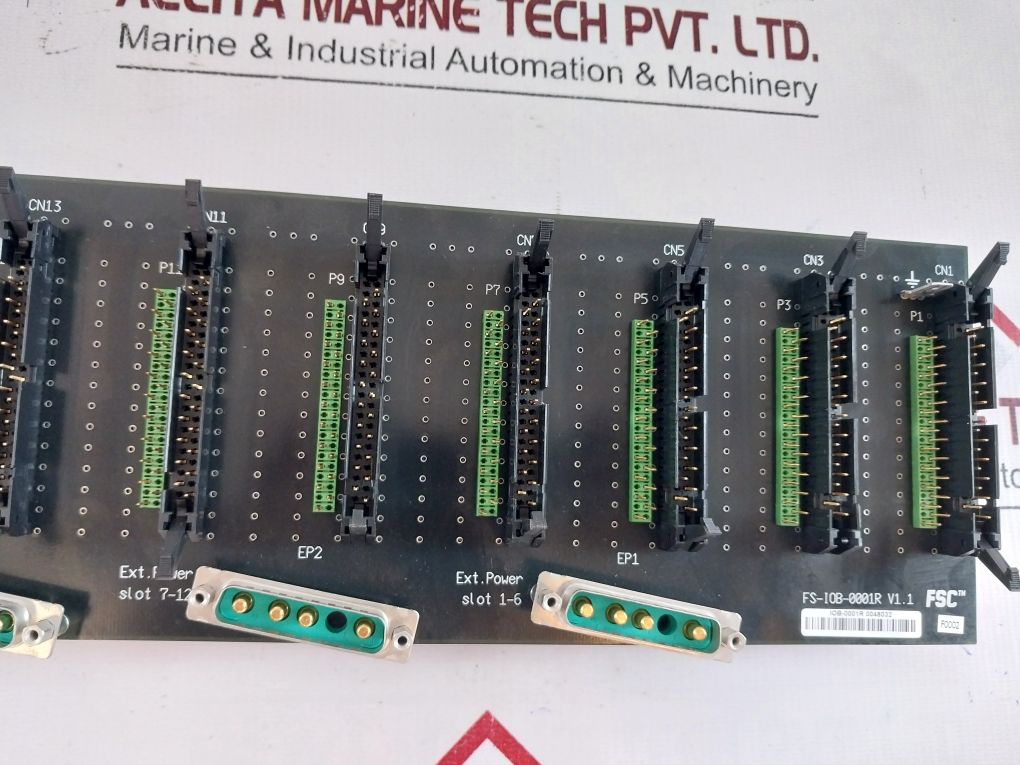

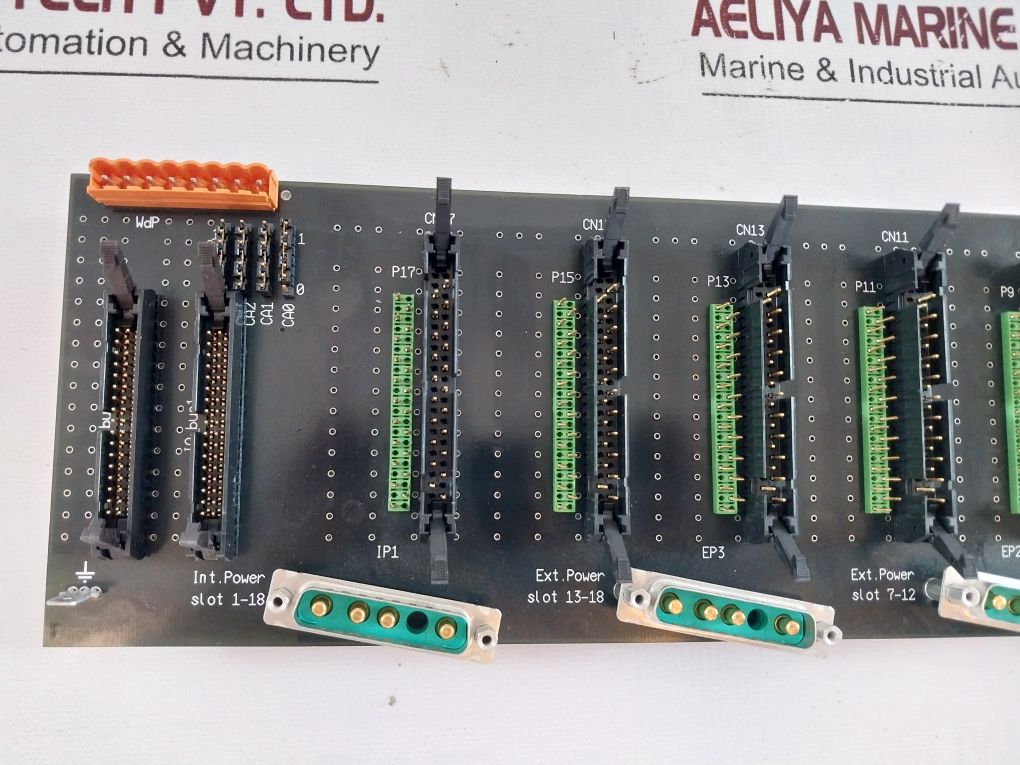

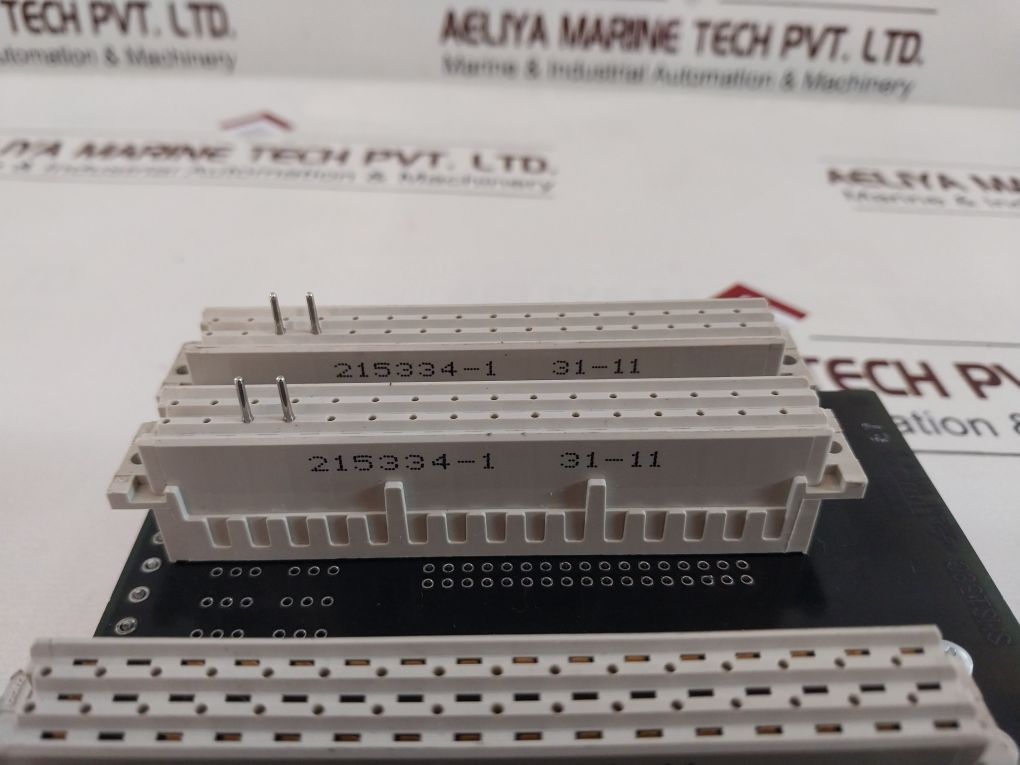

Honeywell Fsc Fs-iob-0001r Base I/O Module

Honeywell

Fsc

Dpmc

Fs-iob-0001r

V1.1

Iob-0001r

0048032

F0002

Sms138c

E117108

94v-0

Weight : 1.200 Kg

Ref No : 67963

What is Honeywell FSC FS-IOB-0001R Base I/O Module?

The Honeywell FSC FS-IOB-0001R Base Input/Output module is designed to connect multiple field devices to the control systems of industrial processes. In this way, it fills the gap between sensors, actuators, and control logic to ensure cohesiveness in the overall system.

Main Features

Multifunctional Connection:

The FS-IOB-0001R module is designed to support various kinds of field devices. It connects digital and analog inputs and output, hence offering high compatibility in all types of sensors and actuators.

Reliable Design:

The module is built to withstand rugged industrial conditions. The enclosure is designed to be robust, which augments its lifespan and reduces the possibility of environmental damage because of dust, moisture, and extreme temperatures.

Easy Integration:

It is smoothly integrated into Honeywell’s control systems hence making it easier to get set up and configured by engineers and technicians. The user-friendly interface makes installation easy by simplifying installation for shorter periods.

Scalability:

It can scale up the FS-IOB-0001R module as the system under configuration expands. As you enlarge your industrial operations, more modules can be added without necessarily changing your configuration settings.

Real-time Monitoring:

With capabilities for real-time data monitoring, this module enables operators to track a host of parameters, thus ensuring rapid response times in case anomalies or changes in system behavior.

Advantages of Using the FS-IOB-0001R Module

Greater Efficiency:

The FS-IOB-0001R module fosters overall efficiency in operations by ensuring that components of a control system communicate effectively with one another. This process ensures that things tend to run smoothly with minimal errors.

Improved Safety:

Realtime monitoring of critical parameters is able to significantly enhance the working environment for all concerned. Potential problems are detected at an earlier stage, thus preventing accidents and breakdowns.

Cost-effectiveness:

Investment in an all-purpose, robust I/O module like FS-IOB-0001R can help an individual derive extensive long-term savings. Such an entity will have reduced costs of maintenance and scalability to avoid investing in new systems with the change in requirements.

Application Flexibility:

The module finds great utility in various industrial applications, which include manufacturing, process control, and building automation. Due to its flexibility, it is a good fit for any kind of control system.

Applications of the Honeywell FS-IOB-0001R Module

The FS-IOB-0001R Base I/O Module can be put to many applications, such as:

Manufacturing Automation:

The module links various sensors and actuators in manufacturing companies to automate machines, conveyor systems, and assembly lines.

Process Control:

The module can be used in a chemical plant or oil refineries as a monitoring and control process for safe and efficient operation.

Building Management Systems:

The FS-IOB-0001R module can be utilized in building automation, integrating it for controlling HVAC systems, lighting, and security devices for the provision of maximum comfort and energy efficiency.

Installation Process

Careful planning and execution are to be followed for the installation of the Honeywell FS-IOB-0001R Base I/O Module. Generally, the following steps describe the installation process:

Planning:

The system requirements and the number of I/O points it needs should be established and the right configuration for the FS-IOB-0001R module chosen.

Mounting:

The installation of the module should be done in a provided control panel or enclosure. The mounting location has to meet the environmental specifications according to its temperature, humidity, and dust requirements.

Wiring:

Follow the wiring diagrams in the installation manual to connect the module to the field devices. Secure and insulate connections.

Configuration

Configure the module according to the configuration of Honeywell’s software tools: communicating parameters, I/O points, and calibration of necessary devices.

Testing:

All the connecting wiring should be tested so that it is confirmed that all of them are working correctly. Input as well as output signals should be checked to confirm that there is correct communication with the control system.

Commissioning:

Once testing is successful, then the module can be incorporated into operational space. It should be monitored for some more time in the initial phase to confirm reliability.

Reviews

There are no reviews yet.