The Birth of the PLC

The PLC was born out of necessity in the automotive industry. In the 1960s, General Motors (GM) sought a solution to the inefficiencies of relay-based control systems used in their manufacturing processes. These systems were cumbersome, prone to failure, and difficult to modify. In response, GM issued a challenge to the engineering community: develop a new control system that was more reliable, flexible, and easier to program.

In 1968, Dick Morley, an engineer at Bedford Associates, answered this call with the invention of the first PLC, the Modicon 084. This groundbreaking device replaced hundreds of relays with a single, programmable unit, dramatically simplifying the control process and paving the way for widespread adoption of PLC technology.

How PLCs Work?

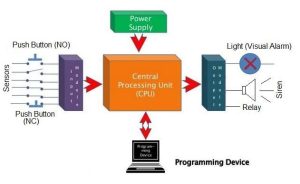

A PLC is a specialized computer designed to control industrial processes. It consists of three main components: the processor (or CPU), input/output (I/O) modules, and a programming device. Here’s a closer look at each component:

Processor (CPU): The CPU is the brain of the PLC. It executes the control program stored in its memory, processes input data, and sends commands to the output devices. Modern CPUs are powerful, capable of handling complex calculations and high-speed operations.

Input/Output (I/O) Modules: I/O modules serve as the interface between the PLC and the outside world. Input modules receive signals from sensors, switches, and other devices, converting them into a form the CPU can process. Output modules, on the other hand, send commands from the CPU to actuators, motors, and other devices, controlling their operation.

Programming Device: The programming device is used to create, modify, and upload the control program to the PLC. Early programming devices were rudimentary, often using punched cards or paper tape. Today, engineers use sophisticated software running on PCs or laptops, offering intuitive graphical interfaces and powerful debugging tools.

Applications of PLCs

PLCs are incredibly versatile, finding applications across a wide range of industries. Some of the key areas where PLCs are used include:

Manufacturing: In manufacturing, PLCs control assembly lines, robotic arms, and other machinery, ensuring precise and efficient operations. They are used in everything from automotive production to food and beverage processing.

Process Control: PLCs are integral to process industries such as oil and gas, chemical, and pharmaceuticals. They regulate variables like temperature, pressure, and flow, maintaining optimal conditions for production.

Building Automation: In building automation, PLCs manage HVAC systems, lighting, and security systems, enhancing energy efficiency and occupant comfort.

Transportation: PLCs are used in transportation systems to control traffic lights, railway signals, and even the operation of trains and subways.

Utilities: Water treatment plants, power generation facilities, and other utility services rely on PLCs for monitoring and control, ensuring reliable and safe operations.

Advantages of PLCs

The widespread adoption of PLCs can be attributed to several key advantages they offer over traditional control systems:

Reliability: PLCs are designed for harsh industrial Automation, with robust hardware and software that minimize downtime and maintenance needs.

Flexibility: PLCs can be easily reprogrammed to adapt to changing processes or requirements, reducing the need for extensive rewiring or hardware changes.

Scalability: From small, standalone systems to large, distributed networks, PLCs can scale to meet the needs of virtually any application.

Integration: Modern PLCs offer seamless integration with other automation systems, including SCADA, DCS, and MES, providing comprehensive control and monitoring capabilities.

Cost-Effectiveness: While the initial investment in a Industrial PLC system can be significant, the long-term benefits in terms of reduced downtime, maintenance, and operational efficiency make it a cost-effective solution.

Function of Programmable Logic Controllers

Automation of Tasks: PLCs can automate repetitive tasks, such as controlling the sequence of operations in a manufacturing process, which increases efficiency and consistency.

Flexibility and Programmability: PLCs can be easily reprogrammed to accommodate changes in the production process or equipment upgrades, offering greater flexibility.

Reliability and Durability: PLCs are robust and reliable, capable of withstanding extreme temperatures, dust, moisture, and electrical noise.

Real-Time Operation: PLCs operate in real-time, meaning they can process inputs and outputs almost instantaneously. This is crucial for tasks requiring precise timing and coordination, such as assembly lines or robotic arms.

Integration and Communication: PLCs can communicate with other devices and systems, such as sensors, actuators, and human-machine interfaces (HMIs), creating a cohesive and integrated control network.

Safety and Monitoring: They enhance safety by monitoring and controlling processes to prevent accidents and ensure compliance with safety standards. PLCs can detect and respond to abnormal conditions, shutting down machinery or triggering alarms.

PLC Programming in the Workplace Today

Automation and Efficiency: PLCs are at the heart of industrial automation. They control machinery, production lines, and complex processes, ensuring operations run smoothly and efficiently. This automation reduces human error, increases production speed, and improves overall efficiency.

Flexibility and Scalability: PLCs can be easily reprogrammed to adapt to changes in production requirements or to accommodate new technologies. This flexibility is essential for businesses looking to stay competitive and responsive to market demands.

Safety and Reliability: PLCs are designed to operate in harsh industrial environments, providing reliable and consistent performance. They also incorporate safety features that protect both the machinery and the workers, reducing the risk of accidents and equipment damage.

Data Collection and Monitoring: Modern PLCs can collect and analyze data in real-time, providing valuable insights into the production process. This data can be used to identify inefficiencies, predict maintenance needs, and improve overall process control.

Cost Savings: By automating repetitive and complex tasks, PLCs help reduce labor costs and minimize downtime. They also contribute to better resource management, reducing waste and operational costs.

Real-World Applications

Manufacturing: PLCs control everything from assembly lines to robotic arms, ensuring precise and efficient production of goods.

Energy Management: PLCs manage turbines, generators, and other critical components, optimizing energy production and distribution.

Building Automation: PLCs are used in HVAC systems, lighting control, and security systems to enhance comfort and safety in commercial buildings.

Transportation: PLCs manage everything from car assembly to traffic light control systems, ensuring smooth and safe operation.

Skills and Training: To work with PLCs, professionals need a solid understanding of programming languages like ladder logic, as well as knowledge of electrical engineering and control systems. Continuous training is essential, as technology evolves rapidly, and new PLC models and software are constantly being developed.

The Future of PLCs

As technology continues to evolve, so too will PLCs. Several trends are shaping the future of PLC technology, promising even greater capabilities and applications:

Internet of Things (IoT): The integration of IoT technology with PLCs is enabling smarter, more connected industrial environments. PLCs can now communicate with a wide range of devices and systems, providing real-time data for improved decision-making and predictive maintenance.

Edge Computing: The advent of edge computing, PLCs are gaining the ability to process data locally, reducing latency and improving responsiveness. This is particularly important for applications that require real-time control and decision-making.

Cybersecurity: As PLCs become more connected, cybersecurity is a growing concern. Future PLCs will incorporate advanced security features to protect against cyber threats, ensuring the integrity and reliability of industrial processes.

Artificial Intelligence (AI): AI is poised to revolutionize PLC programming and operation. AI-driven algorithms can optimize control strategies, predict maintenance needs, and even autonomously adjust processes to improve efficiency and quality.

Open Standards: The adoption of open standards is fostering greater interoperability between PLCs and other industrial automation systems. This is reducing the reliance on proprietary solutions and enabling more flexible, integrated automation architectures.