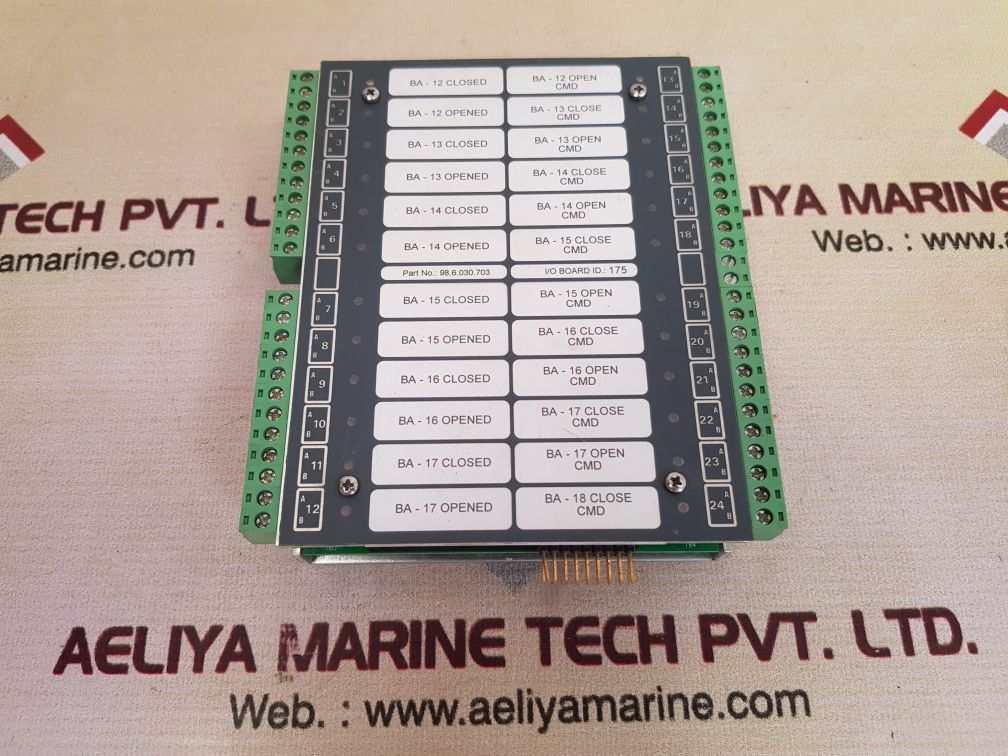

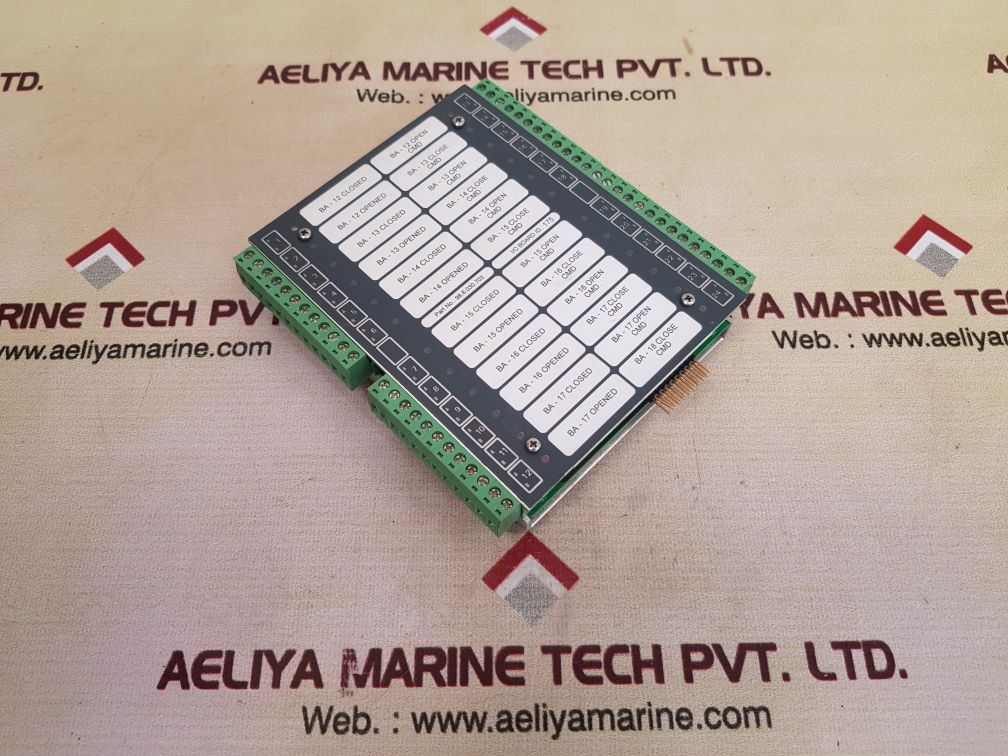

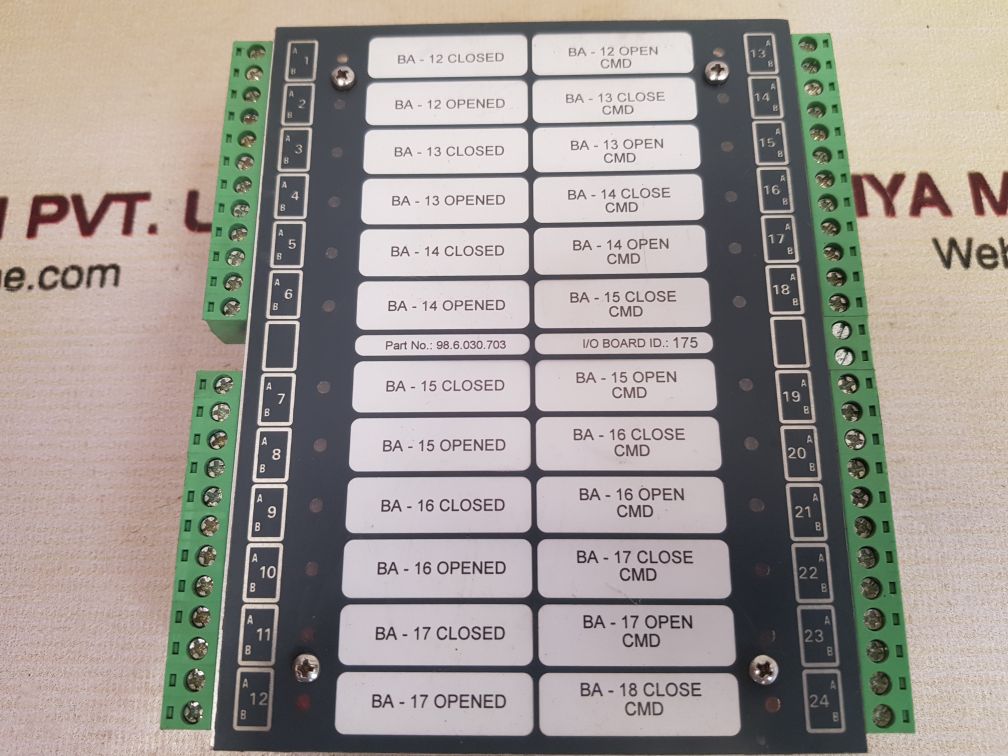

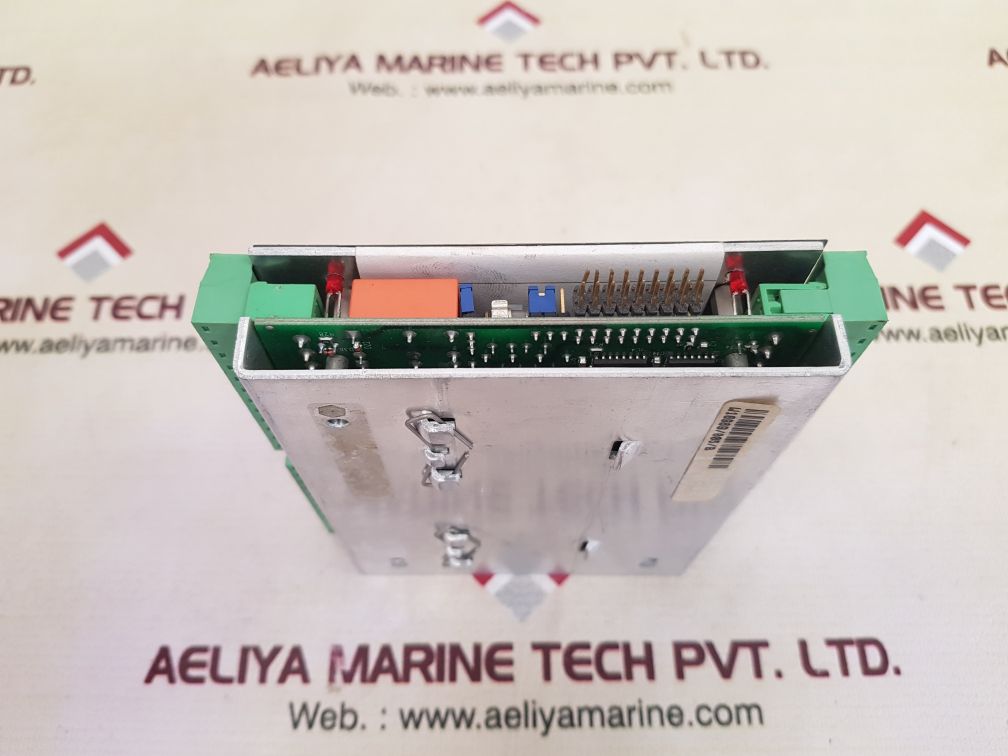

PRAXIS AUTOMATION ID98.6.030.703 I/O BOARD

PRAXIS AUTOMATION

PART NO.: 98.6.030.703

I/O BOARD ID: 175

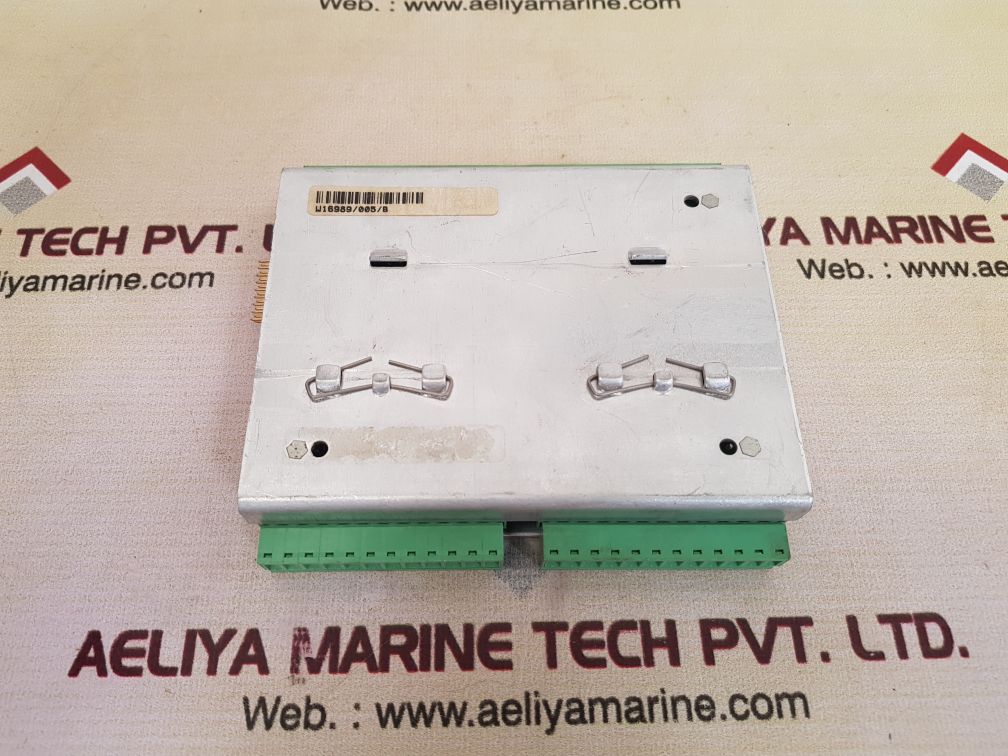

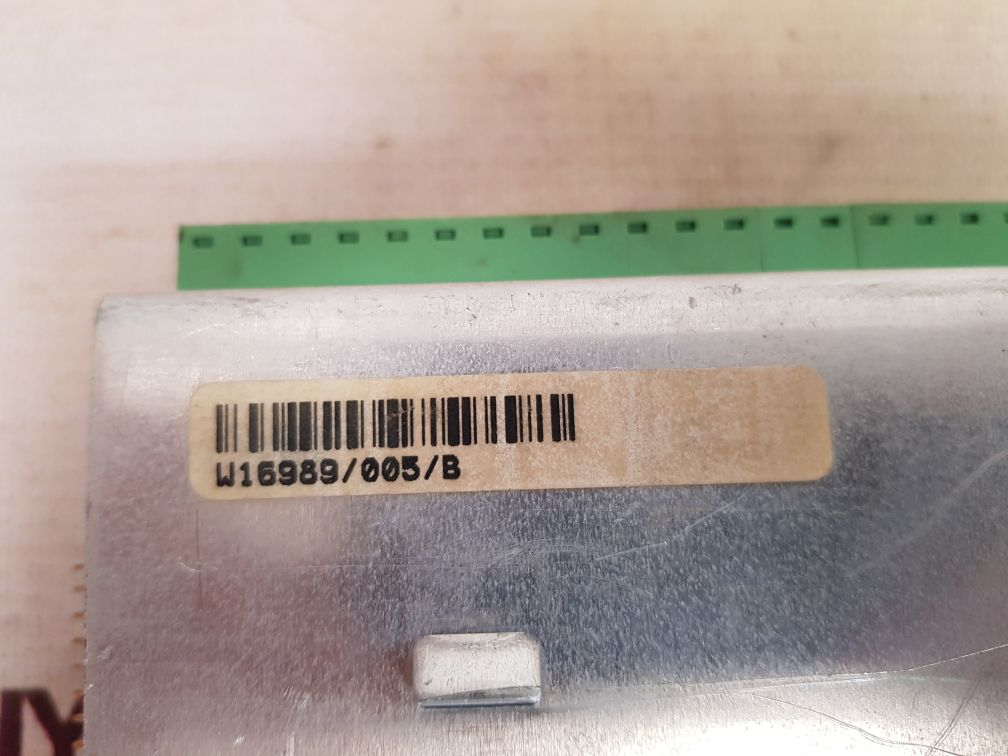

W16989/005/B

WEIGHT : 435 GM

CONDITION : USED 1 PCS

REF NO : 20839

What is an I/O Board?

An Input/Output (I/O) board is essentially a computer expansion card that enables a system to communicate with external devices. Think of it as a bridge between your computer and the real world. It allows your system to receive data from sensors, switches, and other devices, and send commands or data (output) to actuators, displays, and other equipment.

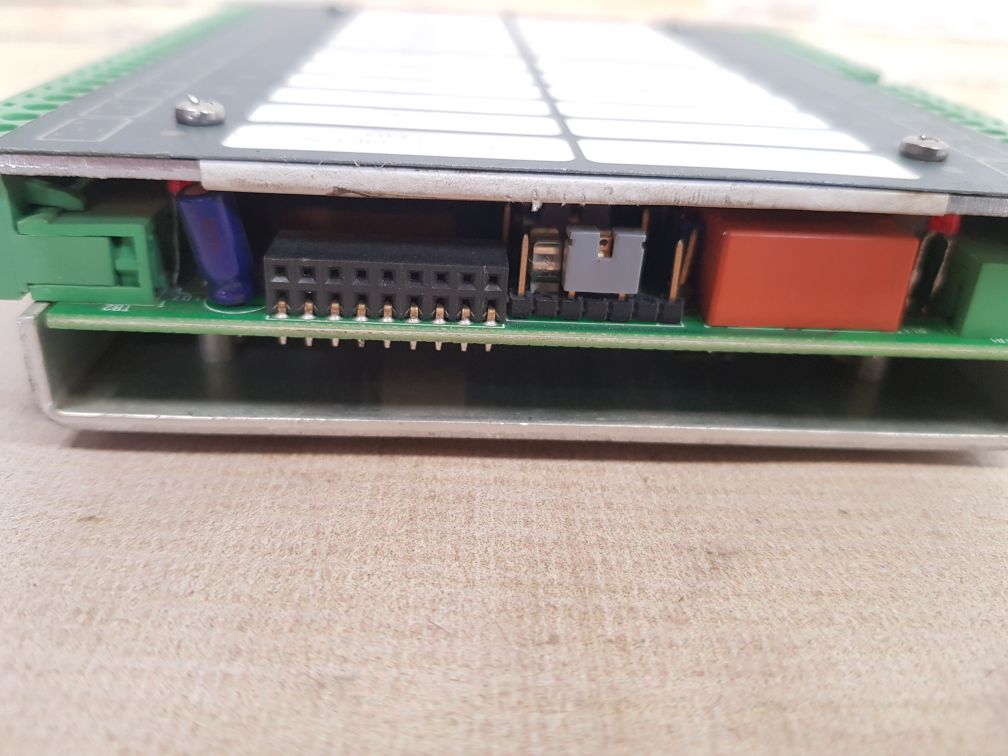

Potential Features of the PRAXIS AUTOMATION ID98.6.030.703 I/O Board

While we don’t have specific information about this particular board, based on common I/O board functionalities, it could potentially include the following features:

- Digital I/O: Handles on/off signals from devices like switches, relays, and sensors.

- Analog I/O: Processes continuous signals from sensors like temperature, pressure, and voltage.

- Counter/Timer: Measures events or time intervals for applications like speed control, frequency measurement, and pulse generation.

- Communication Interfaces: Connects to other devices or networks using protocols like Ethernet, RS-232, or fieldbus.

- Specialized Functions: Depending on the application, the board might have dedicated features like PWM (Pulse Width Modulation) for motor control, or high-speed data acquisition capabilities.

How the PRAXIS AUTOMATION ID98.6.030.703 I/O Board Might Be Used

The potential applications for this I/O board are vast and depend on the specific industry and system it’s integrated into. Here are some general examples:

- Industrial Automation: Controlling production lines, robotics, and machinery.

- Building Automation: Managing HVAC systems, lighting, and security.

- Data Acquisition: Collecting data from sensors for analysis and monitoring.

- Test and Measurement: Acquiring and processing signals for testing and calibration.

- Process Control: Regulating industrial processes based on sensor feedback.

Key Considerations When Using an I/O Board

When working with an I/O board, several factors are crucial:

- Compatibility: Ensure the board is compatible with your system’s hardware and software.

- Input/ Output Channels: Determine the number of input and output channels required for your application.

- Signal Types: Understand the types of signals the board can handle (digital, analog, etc.).

- Performance: Consider factors like data acquisition rate, processing speed, and accuracy.

- Environmental Conditions: Evaluate the board’s suitability for the operating environment (temperature, humidity, etc.).

- Software Support: Assess the availability of software drivers and development tools.

Maximizing the Potential of Your I/O Board

To fully leverage the capabilities of your PRAXIS AUTOMATION ID98.6.030.703 I/O board, consider the following tips:

- Thorough Documentation: Refer to the board’s user manual for detailed specifications and instructions.

- Proper Installation: Ensure correct installation and configuration of the board.

- Effective Software Integration: Utilize appropriate software to program and control the board.

- Regular Maintenance: Perform routine checks and maintenance to optimize performance.

- Continuous Learning: Stay updated on the latest I/O board technologies and best practices.