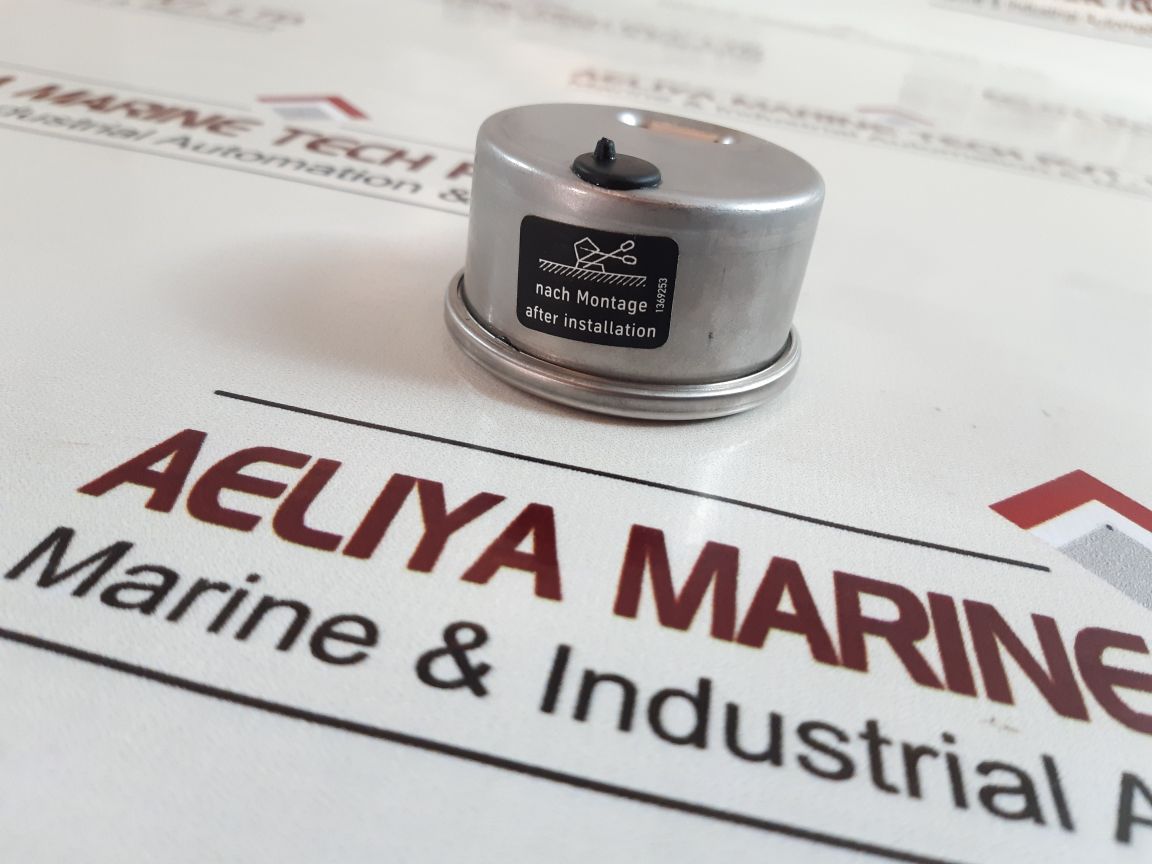

WIKA EN 837-1 PRESSURE GAUGE 0 TO 16 BAR

WIKA

0 TO 16 BAR

316 SS

EN 837-1

8970007098

CL 1.6

1369253

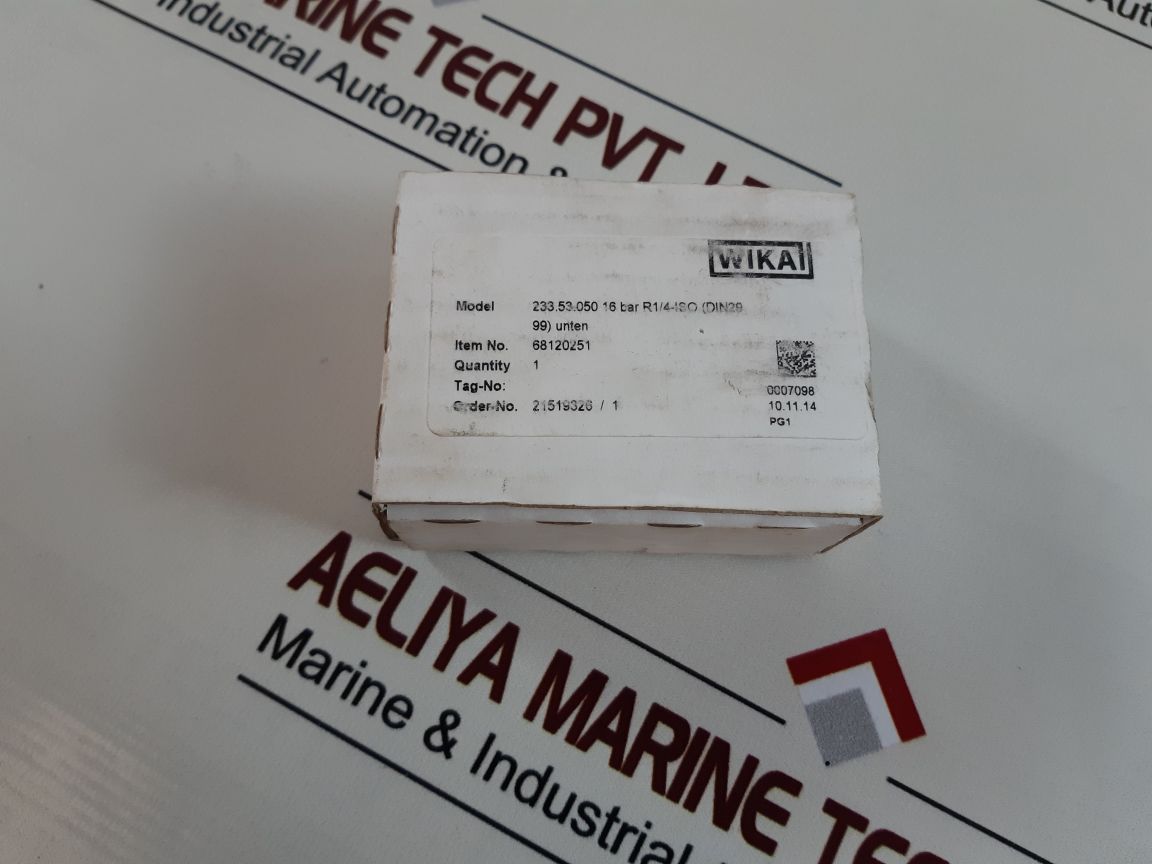

MODEL: 233.53.050 16 BAR R1/4-ISO (DIN29 99) UNTEN/BELOW

ITEM NO: 68120251

ORDER NO.: 21519326/1

0007098

WEIGHT : 160 GM

CONDITION : NEW 2 PCS

REF NO : 51261

What is WIKA EN 837-1 Pressure Gauge?

WIKA EN 837-1 Pressure gauge mechanical gauges series, used for measuring the pressure of liquids or gases. “EN 837-1” is an abbreviation of the European standard that applies to the design and manufacturing process, as well as to the accuracy of pressure gauges. This standard has met strict quality standards; the gauge should be used to operate virtually in any industrial environment, from hydraulics, pneumatics, through to process control.

The 0 to 16 bar model finds especial utility in all those applications where intermediate pressure measurement is required at regular intervals, like in chemical plants, water treatment facilities, oil refineries, and mechanical engineering industries.

Key features:

1. Material of High Quality

WIKA pressure gauges are strongly built. Housing is often stainless steel, anti-rust and sturdy enough to withstand wear on operation over time, even in harsh environments. The inner parts, such as the bourdon tube, are usually made of copper alloys or stainless steels depending on the demand of the application.

2. Precision and Accuracy

WIKA EN 837-1 gauges have precision accuracy, which is often between the classes of ±1.0% to ±2.5%. Therefore, they can produce accurate readings needed for ensuring that industrial systems operate in a safe and efficient manner.

3. Rugged Assembly

This gauge is designed for challenging conditions. It can endure high pressure without losing its performance capabilities. Apart from that, the WIKA EN 837-1 is provided as glycerine-filled models that reduce vibrations and thus protect the gauge from pulsation effects; an adverse condition faced in dynamic applications.

Applications

The 0 to 16 bar range makes this pressure gauge versatile. It is used in various industries, which include but are not limited to:

Manufacturing and Processing Plants: Used in compressors, hydraulic systems, and pressurized tanks.

Water Management: This is done to maintain a given constant pressure level in the water treatment and distribution system.

Oil & Gas: Used to monitor pressure in pipelines and refineries and gas processing plants.

HVAC Systems: This is used in the maintenance and monitoring pressure levels of heating, ventilation, and air conditioning systems.

Meets the EN 837-1 Standard

There is a wide range of pressure gauges covered by the European Standard EN 837-1, which will guarantee that the WIKA gauge falls within the required safety and performance criteria. This means compliance will instill confidence in the user that an instrument will give reliable and repeatable results.

Working Principle of Pressure Gauge

If one understands the fundamental working principle of a pressure gauge, this might help appreciate its value in the industrial setting.

This transducer employs the bourdon tube principle; essentially, it is a coiled tube that is connected to the source of the pressure. When the fluid or gas applies force to this tube, it slightly straightens it. Then, this movement is transmitted to the dial via a pointer which reflects the level of the pressure. The more the pressure is raised, the more the tube straightens and the more the pointer moves.

This simple yet strong mechanism has been in use for many years, reputationally known as highly reliable and accurate.

Advantages of the WIKA EN 837-1 Pressure Gauge

1. Reliability in Harsh Environments

The robust structure of the WIKA pressure gauge makes it ideal for industrial applications where conditions such as temperature changes, corrosive media, and mechanical shock may exist in the working environment. For example, the use of stainless steel for the casing prevents corrosion and impacts from external sources.

2. Ease of Use and Installation

The WIKA EN 837-1 pressure gauge is mechanical in nature, which is very easy setup and requires a very minimal maintenance cycle, you will not require external powers to operate it-this automatically makes its application in most remote locations or places simply hard to access electricity easy.

3. Cost-Effective Solution

Unlike other advanced digital pressure sensors, mechanical gauges, such as WIKA EN 837-1, are more economical pressure monitoring without compromising accuracy; thus, these devices are ideal for applications that want reliable pressure readings without breaking the bank to avoid the higher costs of digital systems.

4. Safety

For this reason, pressure needs to be measured with precise accuracy to avoid system failure, leakage, or even explosion in high-pressure systems. WIKA EN 837-1 Gauge ensures consistent reading; therefore, it can detect whether the operators operate at the normal pressure levels or if the readings are different.

5. Flexibility

The WIKA EN 837-1 pressure gauge is one of the most easily accessible pressure measuring instruments, from small-scale applications to industrial large-scale processes. A 0 to 16 bar range serves most of the widely common industrial pressures.