| Attribute | Value |

|---|---|

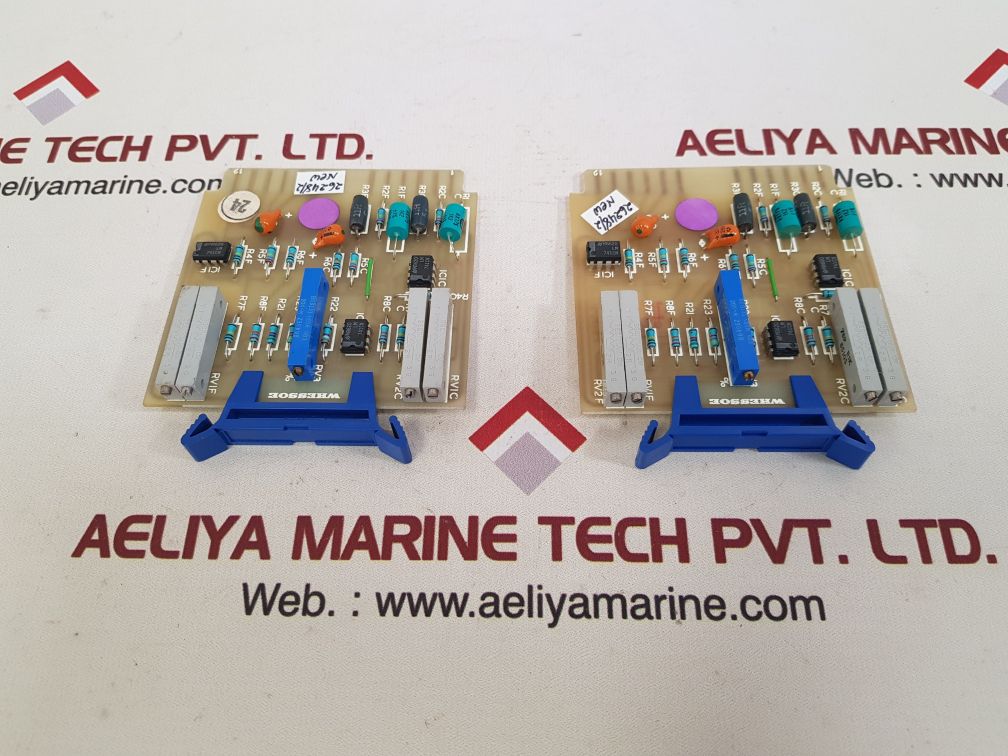

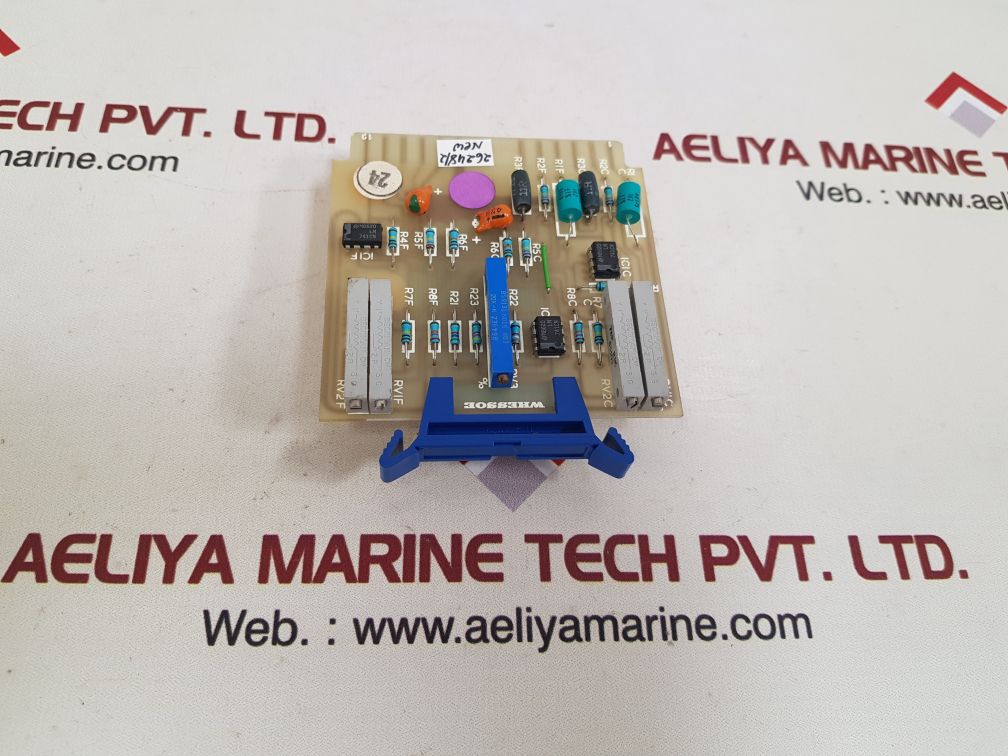

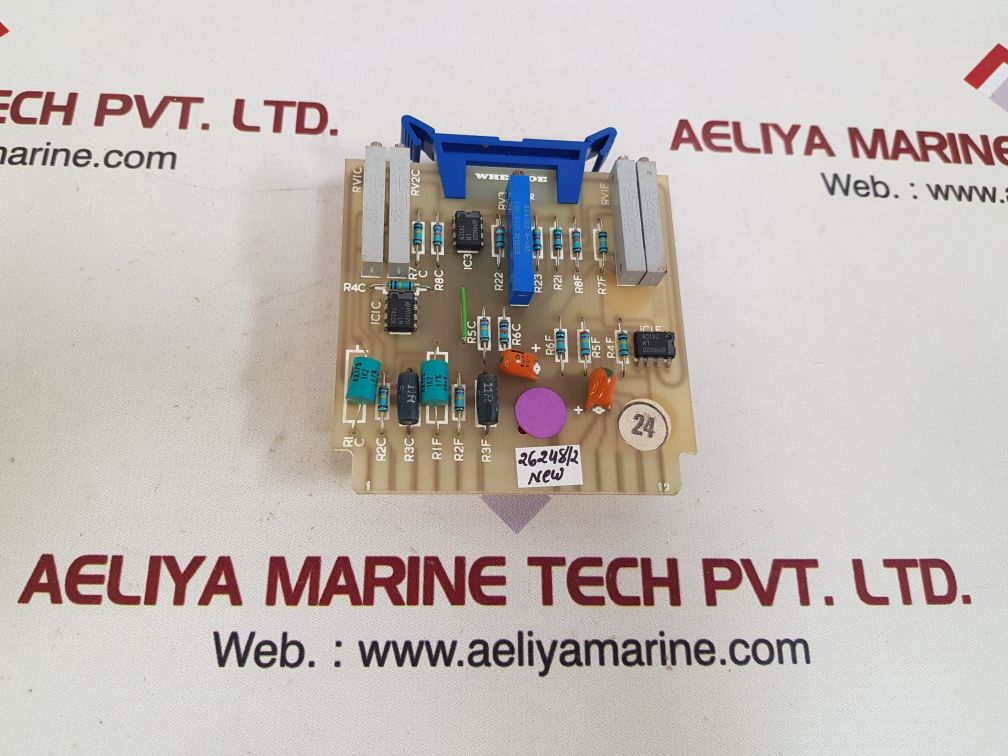

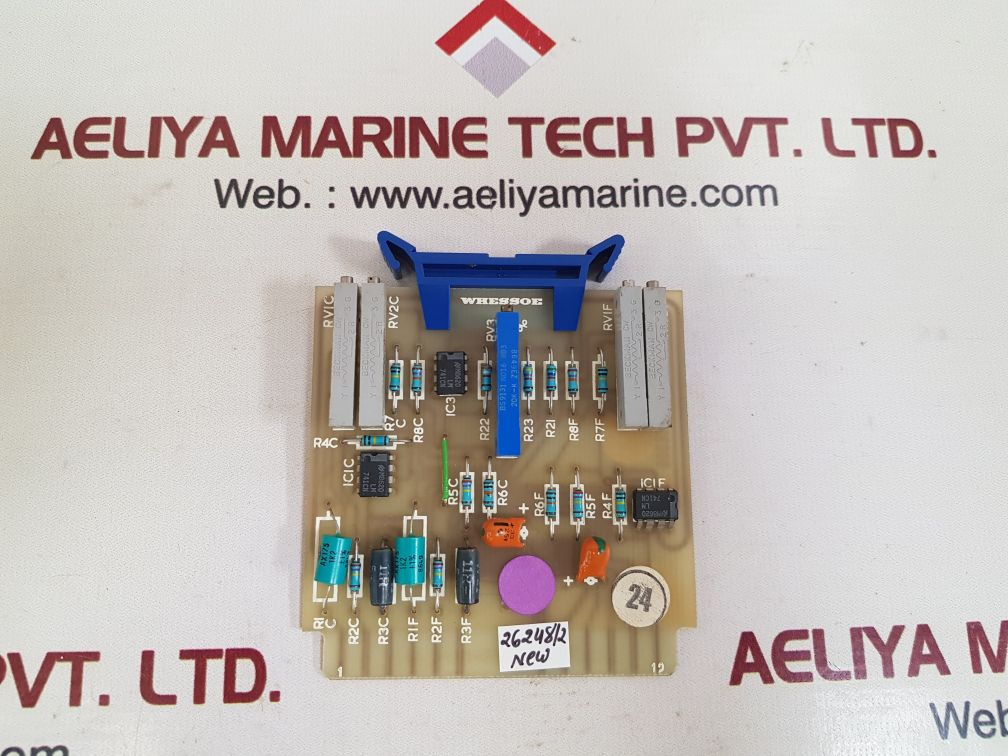

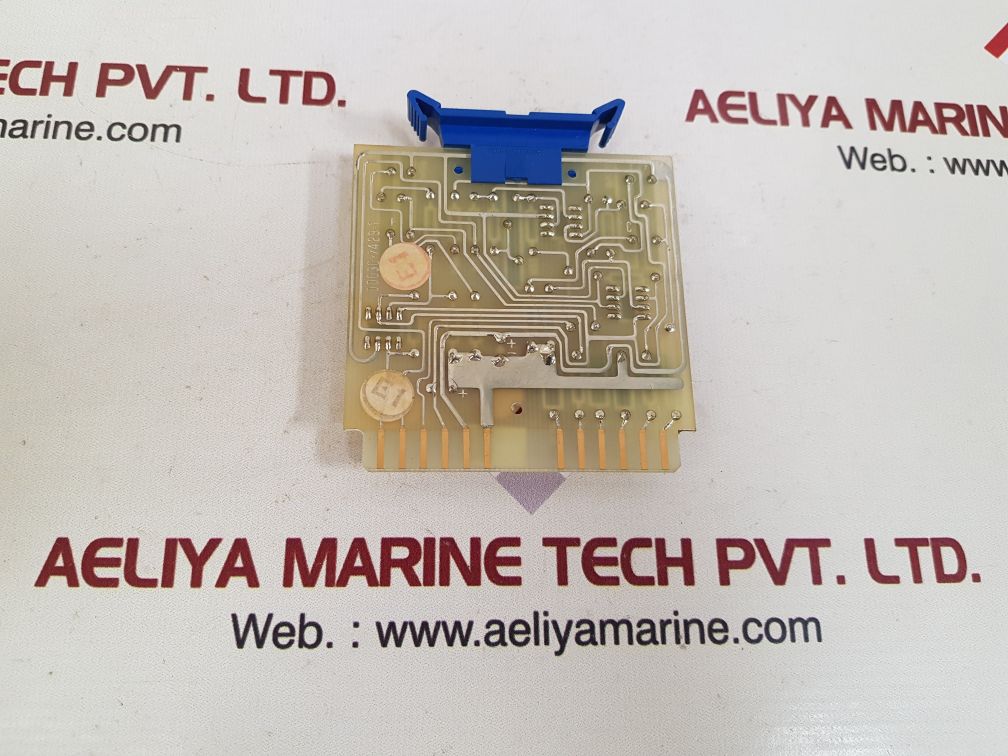

| Brand | Whessoe |

| Part Number | 00030-7429-1 |

| Product Type | Level Input Module |

| Model | 98-NS5-5253 |

| Code | 020110 |

| Weight | 100 gm |

What is the Whessoe 00030-7429-1 Level Input Module?

The Whessoe 00030-7429-1 is a precision level input module designed to measure liquid levels in process vessels and storage tanks. Produced by Whessoe, a renowned industrial instrumentation brand, the module is designed for integration into bigger control and safety systems to provide safe, continuous operation in harsh environments.

Usually combined with Whessoe radar or ultrasonic sensors, the module receives entering level signals and transmits them effectively to control units for dynamic monitoring.

Top Features and Advantage

Some are the key features that make 00030-7429-1 module stand out as an industrial automation solution of choice:

High Sensitivity and Precision: Capable of reading and processing subtle-level modifications, providing true tank level outputs.

Durable Construction: Designed for rugged environment use, it provides immunity to dust, vibration, and temperature fluctuations.

Modular Architecture: May be easily interfaced with any existing SCADA, DCS, or PLC system without large system upgrades.

Low Service Life: Post-installation maintenance is minimal, minimizing downtime operations.

Isolation of the Signal: Provides galvanic isolation to suppress signal interference and shield downstream electronics.

Technical Specifications

Model Number: 00030-7429-1

Alternate Code: 98-NS5-5253

Input Type: Analog level signal (usually 4–20 mA or resistance-based)

Output: Transmitted to controller/PLC

Mounting: DIN-rail compatible

Operating Voltage: Standard 24V DC (verify actual device label for details)

Certifications: Most likely complies with ATEX, IECEx standards (in accordance with Whessoe’s general industrial compliance)

Applications

The Whessoe 00030-7429-1 is utilized in a range of industries for precise liquid level measurement, particularly in situations where hazardous substances or stringent safety requirements are present.

1. Oil & Gas Terminals

Utilized for fuel level monitoring in storage tanks, preventing overfills and ensuring safe transfer operations.

2. Chemical Manufacturing

Provides accurate level measurement of reactive or dangerous chemicals where stability and measurement integrity are crucial.

3. Marine Industry

Typically installed in cargo or ballast tanks, allowing robust measurement under dynamic conditions like vessel movement and changing pressures.

4. Pharmaceuticals and Food Processing

Sensor provides accurate level inputs necessary for batch processing and quality control.