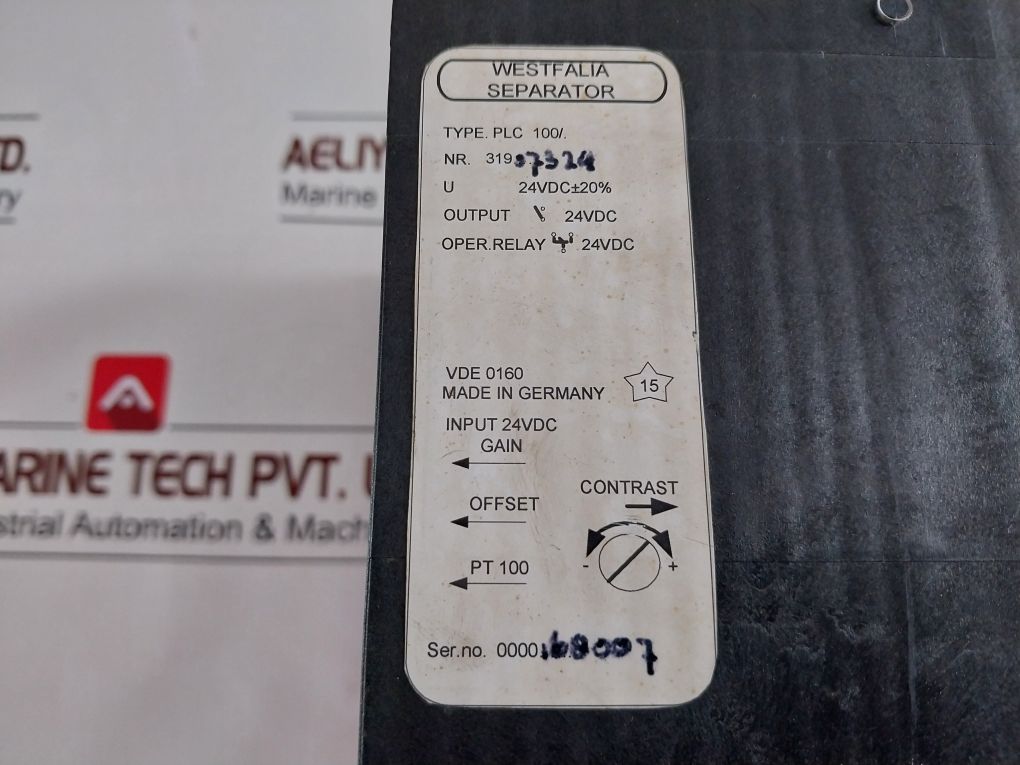

| Attribute | Value |

|---|---|

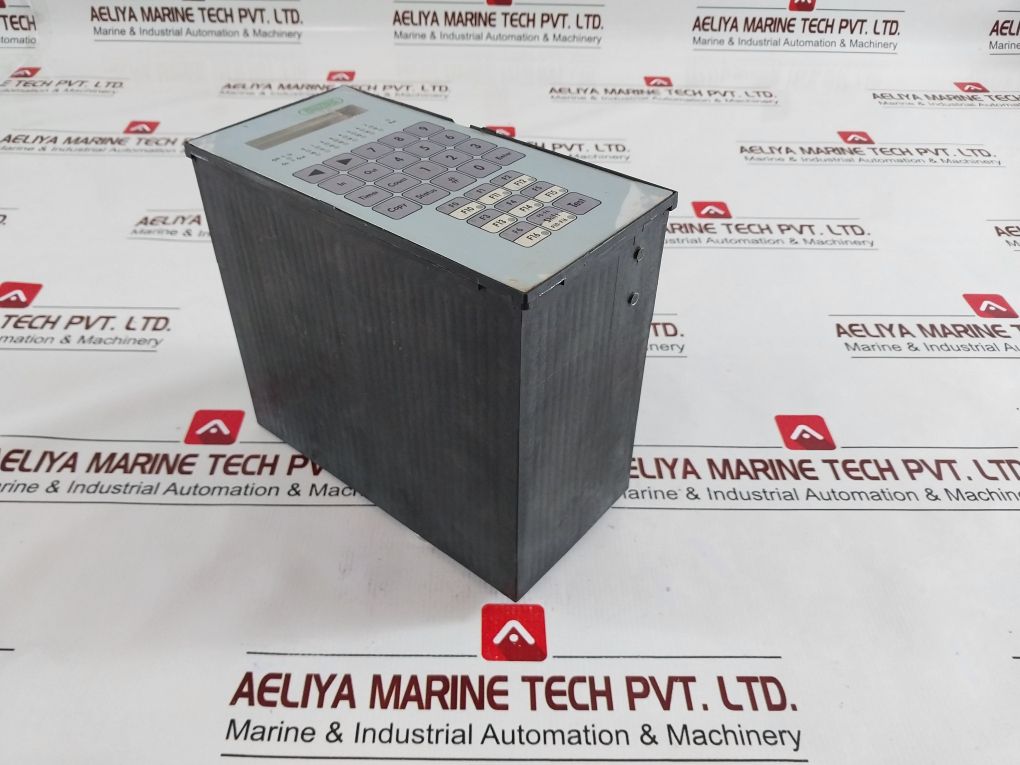

| Product Name | Westfalia Separator PLC 100 Control System |

| Brand | Westfalia Separator |

| Type | PLC 100/ |

| Nr. | 31997324 |

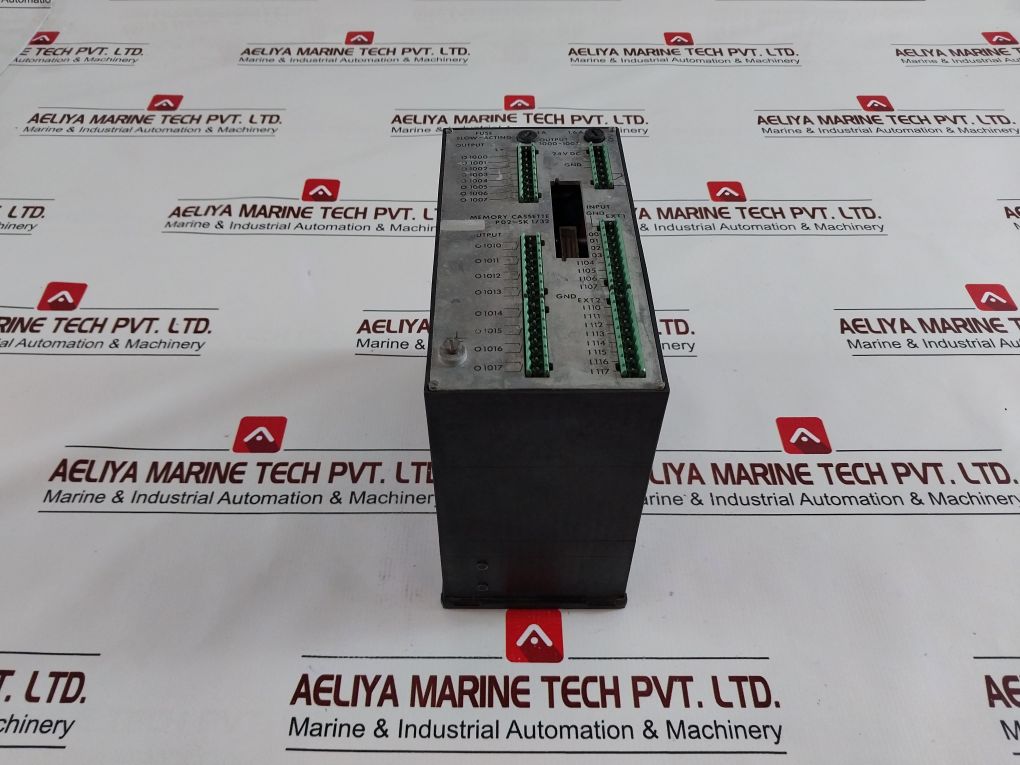

| Voltage (U) | 24VDC ±20% |

| Output / Input / Operating Relay | 24VDC |

| Standard | VDE 0160 |

| Temperature Sensor | PT100 |

| Output Range | 1000–1007 |

| Memory Cassette | P02-SK 1/32 |

| Country of Origin | Made in Germany |

| Weight | 1.160 Kg |

| Ref No | 60062 |

What Is the Westfalia Separator PLC 100 Control System?

The Westfalia Separator PLC 100 Control System is a programmable logic controller designed to manage, monitor, and automate the operation of Westfalia separation units.

It acts as the separator’s central brain, which controls the execution of tasks, including:

- Bowl speed regulation

- Feed control

- Discharge cycles

- Vibration monitoring

- Temperature and pressure supervision

- Safety interlocking

Westfalia PLC 100 ensures optimum performance of the separator and minimizes manual intervention, reducing the risk of operational errors.

Key Features of the Westfalia Separator PLC 100

1. Intelligent Automation

The PLC automates all major separator processes, enabling consistent output and reduced human error.

2. Real-time Monitoring

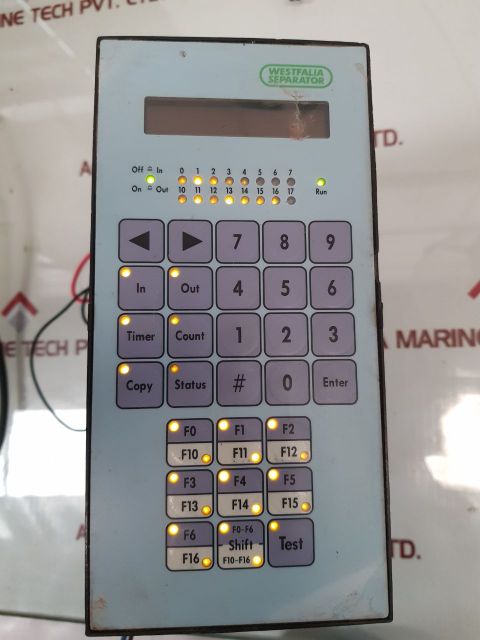

It constantly monitors the speed, vibration, temperature, and operation parameters to keep the system stable and safe.

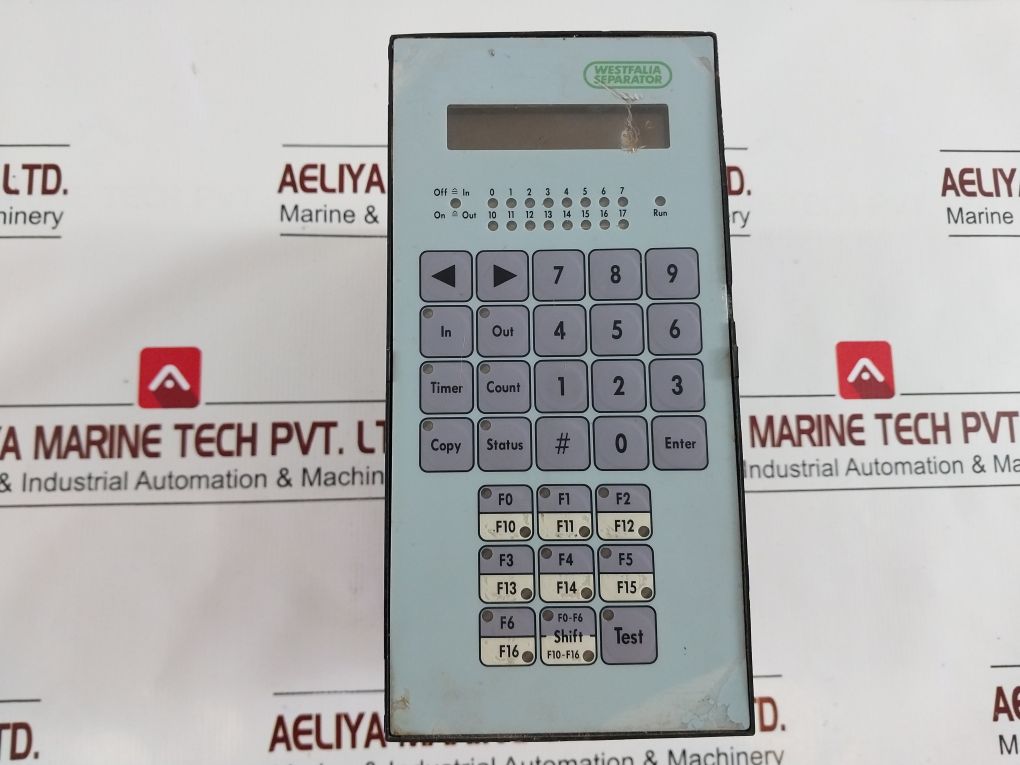

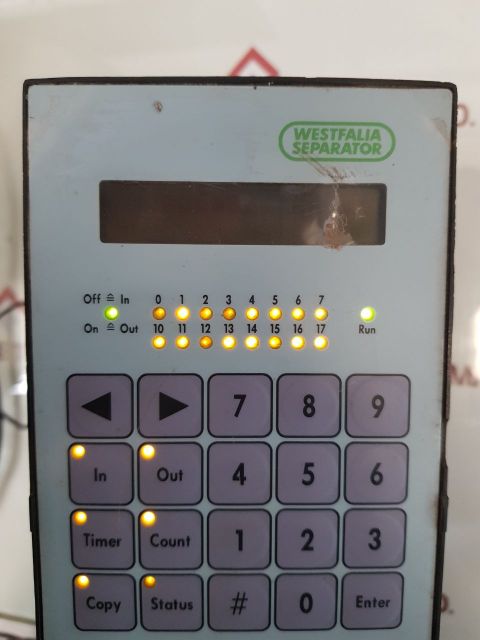

3. User-Friendly Interface

The control system allows easy navigation, fast update of the parameters, and intuitive status displays.

4. Advanced Safety Protection

Equipped with alarms, fault detection, emergency shutdowns, and interlocks, this assures safe operation under extreme conditions.

5. High Compatibility

Works seamlessly with various Westfalia separator models used across marine and industrial environments.

6. Industrial Design Durability

Built to operate reliably under vibration, extreme temperatures, and high-humidity marine environments.

7. Data Logging and Diagnostics

History data, fault logs, and performance reports can be used for troubleshooting.

8. Energy-Efficient Control

Optimizes bowl speed, feed flow, and discharge timing to reduce energy consumption.

Applications of Westfalia Separator PLC 100 Control System

The PLC 100 is widely used across industries where separation and purification processes are critical.

Overview Marine Sector

- Fuel oil purification

- Lube oil separation

- Bilge water treatment

- Diesel Oil Treatment Systems

- Engine room auxiliary systems

Industrial Applications

- Edible oil processing

- Beverage & dairy separation

- Biofuel refining

- Chemical and pharmaceutical production

- Wastewater treatment plants

- Nuclear Power Plants

- Turbine lube oil purification

- Boiler feedwater treatment

- Cooling system filtration

Food & Beverage Industry

- Dairy cream separation

- Juice clarification

- Brewery processes

The PLC 100 increases process stability, ensuring consistent product quality and continuous operation within these industries.

Why Choose the Westfalia Separator PLC 100 Control System?

1. Proven Reliability

Westfalia is a world-renowned brand with a reputation for providing high-precision separation technology. The PLC 100 offers reliability and robust automation control.

2. Reduced Downtime

Precise diagnostics and speedy fault detection minimize time-consuming troubleshooting and avoid sudden failures.

3. Improved Productivity

In this context, automated control will help enhance separation performance, optimize energy consumption, and raise overall productivity.

4. Easy Integration

The system is designed to fit effortlessly with existing Westfalia separation units and to reduce installation and training time.

5. Reduced Operational Costs

Automation of critical functions reduces manual labor, saves energy from being wasted, and prolongs the life of equipment.

6. High Safety Standards

Equipped with advanced alarm and protection features to provide safe operation in harsh marine and industrial conditions.

7. Long-Term Durability

It is engineered for long operational life, making it a smart investment for industries needing continuous separation processes.