| Attribute | Value |

|---|---|

| Brand | Wartsila |

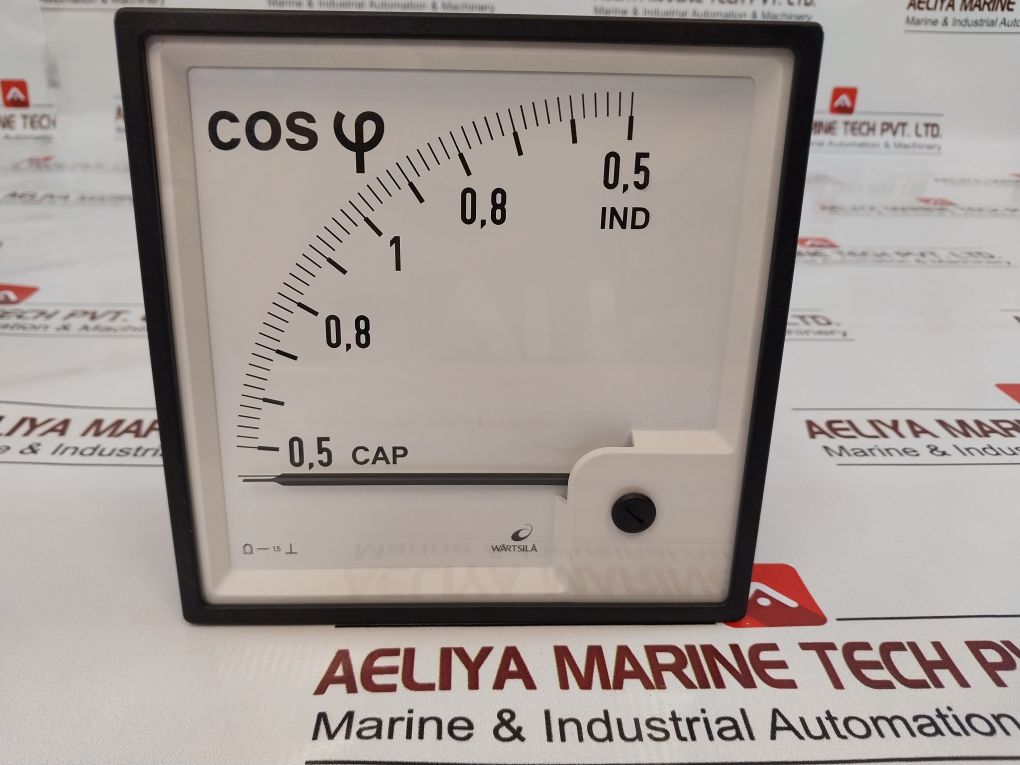

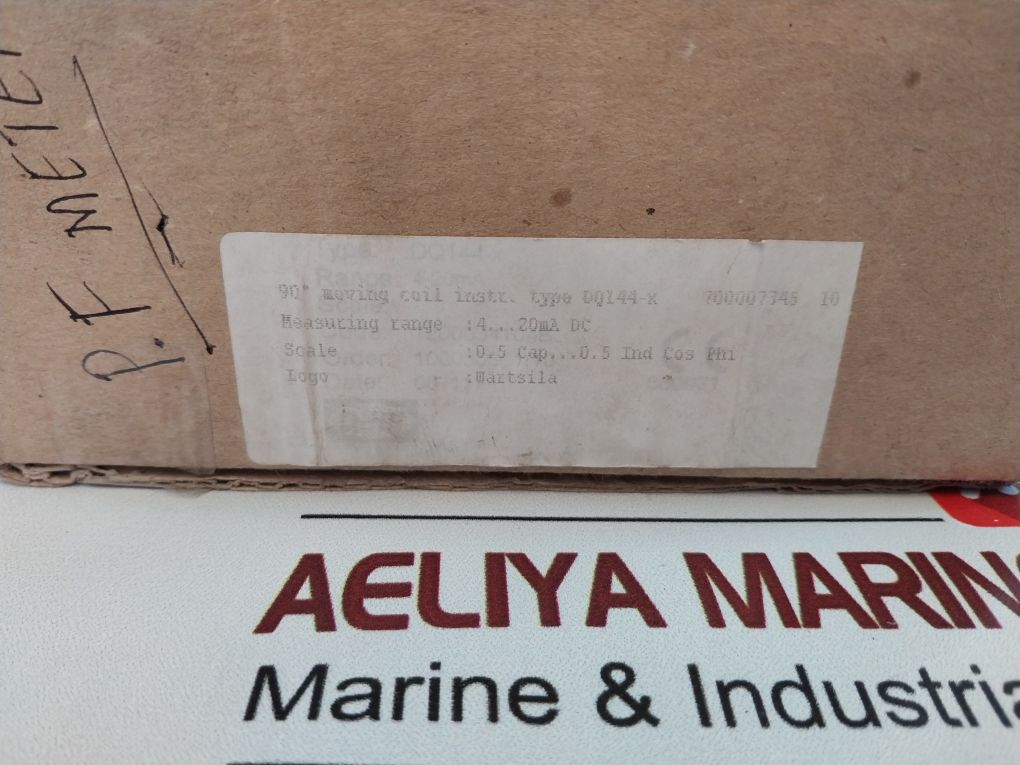

| Model / Type | DQ144-X |

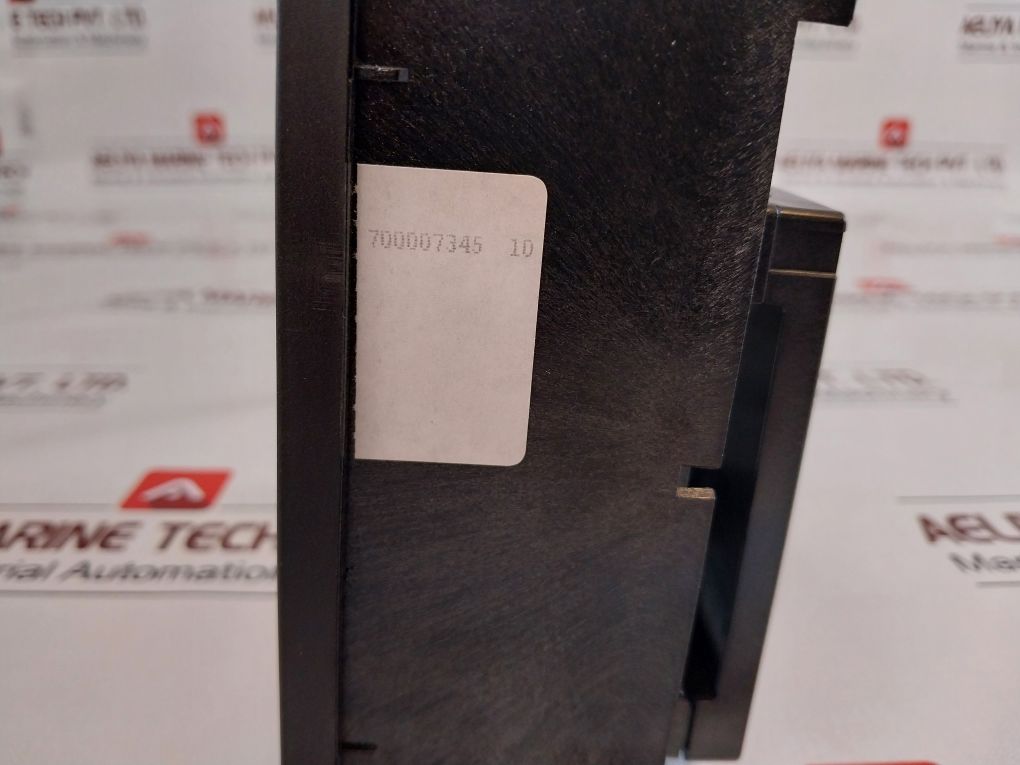

| Part Numbers | 1200034104B / 560971 / 700007345 10 |

| Instrument Type | 90° Moving Coil Instrument |

| Measuring Range | 4…20 mA DC |

| Scale | 0.5 Cap … 0.5 Ind Cos Φ (Phi) |

| Country of Origin | Europe |

| Weight | 460 gm |

| Condition | New – 1 Pcs |

| Ref No | 58857 |

What is the Wartsila DQ144-X Meter?

The Wartsila DQ144-X Meter is a high-precision electrical measurement device for the monitoring of key electrical parameters such as voltage, current, frequency, and power output. Built by Wärtsilä, a globally trusted name in marine power solutions, this meter has been engineered for harsh maritime environments where reliability and precision are non-negotiable.

It helps the ship operator, engineers, and technicians monitor power quality, system load, engine performance, and general electrical health. Moreover, with robust components and steady performance, it is very significant in breakdown prevention, fault reduction, and safe navigation.

Key Features of Wartsila DQ144-X Meter

1. High-Accuracy Marine-Grade Measurement

It is designed to give accurate electrical readings and maintain consistency under variable loads, as well as harsh marine conditions.

2. Rugged Construction for Harsh Environments

Wartsila meters are known for:

- corrosion-resistant design

- vibration tolerance

- long service life

This makes the DQ144-X suitable for engine rooms, control panels, and offshore platforms.

3. Wide Measurement Range

It can monitor several electrical parameters, thus providing complete visibility for the power system.

4. Easy Installation & Integration

The compact, modular design fits directly into existing marine or industrial control panels without major modifications.

5. Stable Output & Reliable Performance

Its accuracy ensures a proper flow of information continuously to the automation systems, SCADA setups, and control modules.

6. Backlit Display or Panel-Mounted Visibility

Depending on the variant and configuration, it provides readable measurements even in low-light engine rooms.

7. Compatible with marine automation systems

Works seamlessly with generator controllers, synchronizers, power management systems, and monitoring devices used in ships.

Applications of the Wartsila DQ144-X meter

The Wartsila DQ144-X meter is widely used in multiple critical areas, both in marine and industrial environments.

Marine Applications

- Main Engine Power Monitoring

- Auxiliary Engine Electrical Output Measurement

- Generator Panels & Switchboards

- Bridge and Navigation Systems

- Marine Automation & PMS Systems

- Engine Room Control Panels

Industrial Applications

- Power plants

- Heavy machinery panels

- Industrial switchboards

- Manufacturing systems

- HVAC & large pump setups

- Process automation equipment

Offshore & Energy Sector

- Oil & gas platforms

- Offshore power distribution units

- Renewable energy systems: wind, marine engines

Wherever electrical precision and system stability are essential, the Wartsila DQ144-X finds its place.

Why Choose the Wartsila DQ144-X Meter?

1. Trusted Global Brand

Wartsila is among the world’s major manufacturers of marine engines, energy systems, and automation components. Their meters ensure reliability and long operational lives.

2. Exceptional Accuracy

Precise measurement minimizes the risk of overloads, failures, and system imbalances, hence it is crucial for ship safety and industrial productivity.

3. Built for Tough Marine Conditions

Saltwater, vibration, heat, and humidity-the meter is designed to perform faultlessly under those harsh maritime conditions.

4. Long-Lasting & Low Maintenance

Its robust design means it requires little maintenance, reducing downtime and minimizing operational costs.

5. Perfect for Retrofitting

The DQ144-X is a very convenient and compatible replacement when upgrading older marine systems; it is ideal for retrofit projects.

6. Supports Safe & Efficient Operations

Engineers depend on the stable performance of it to keep the electrical system healthy, avoid equipment failure, and ensure continuous operation.