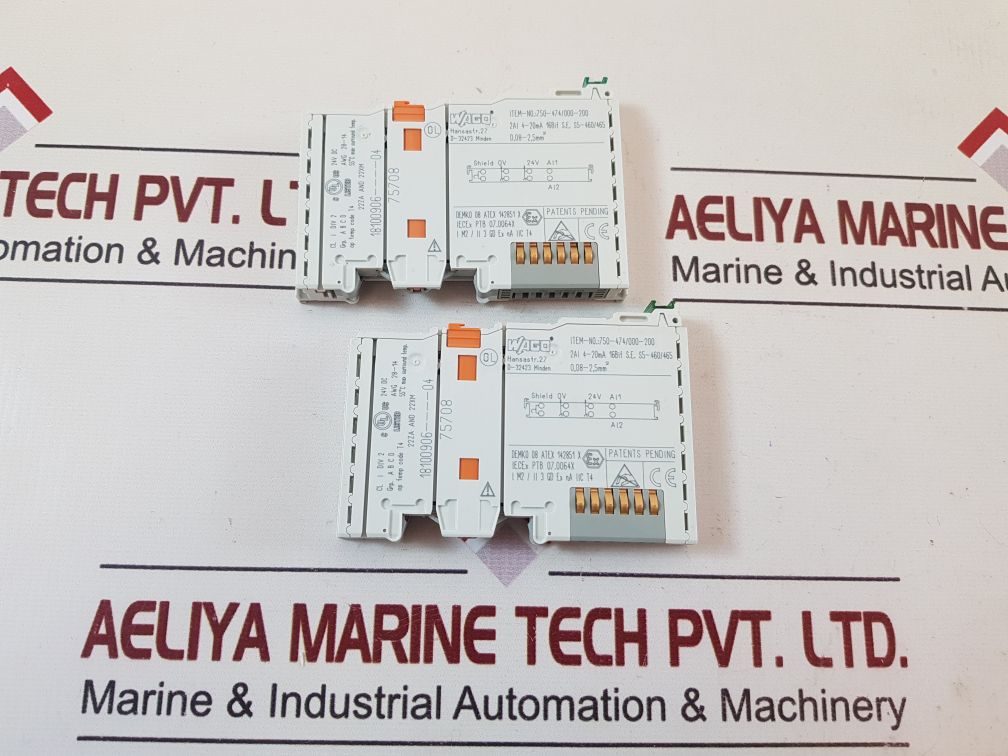

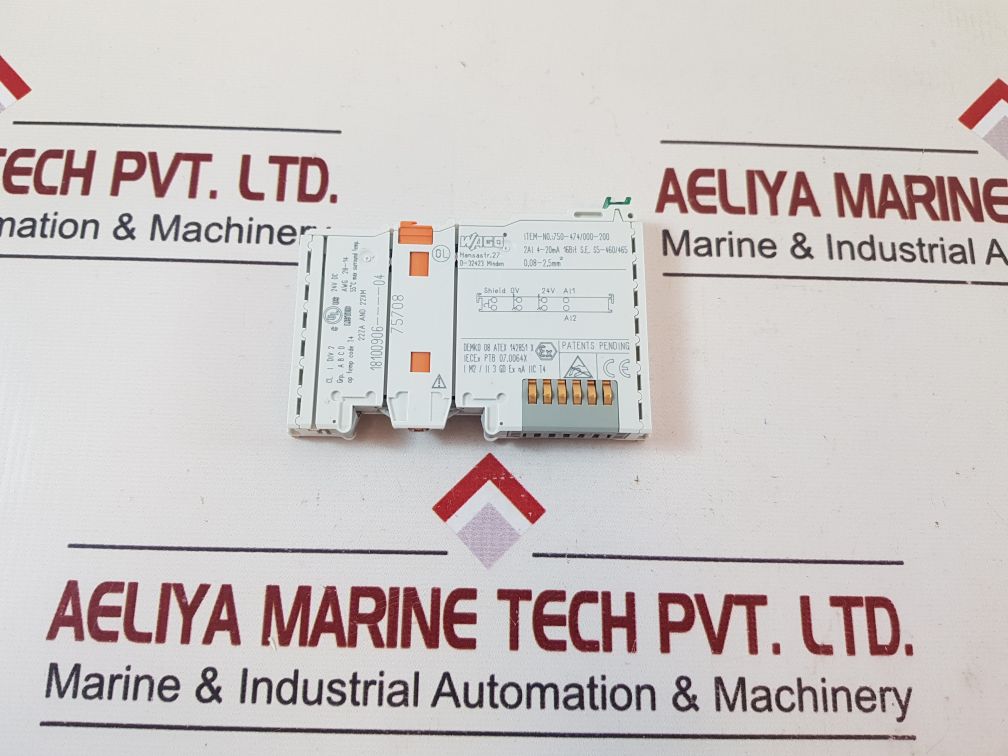

| Attribute | Value |

|---|---|

| Maker | WAGO Corporation |

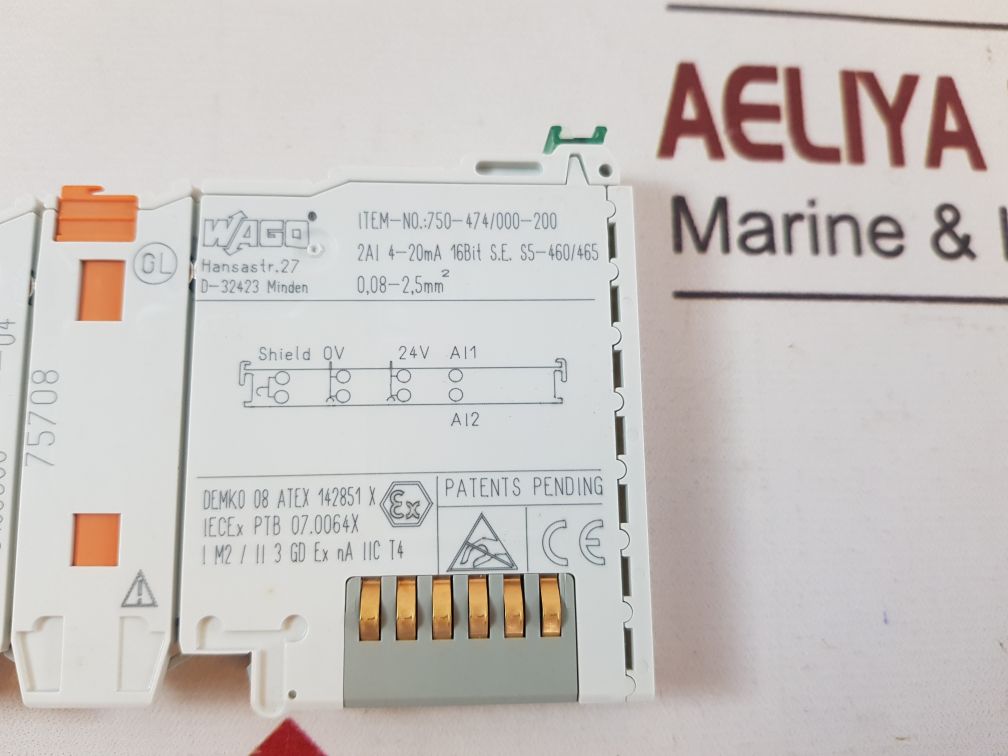

| Item No. | 750-474/000-200 |

| Description | 2AI 4-20MA 16BIT S.E. S5-460/465 |

| Connection Size | 0.08-2.5MM² |

| Certification | DEMKO 08 ATEX 142851X, IECEX PTB 07.0064X |

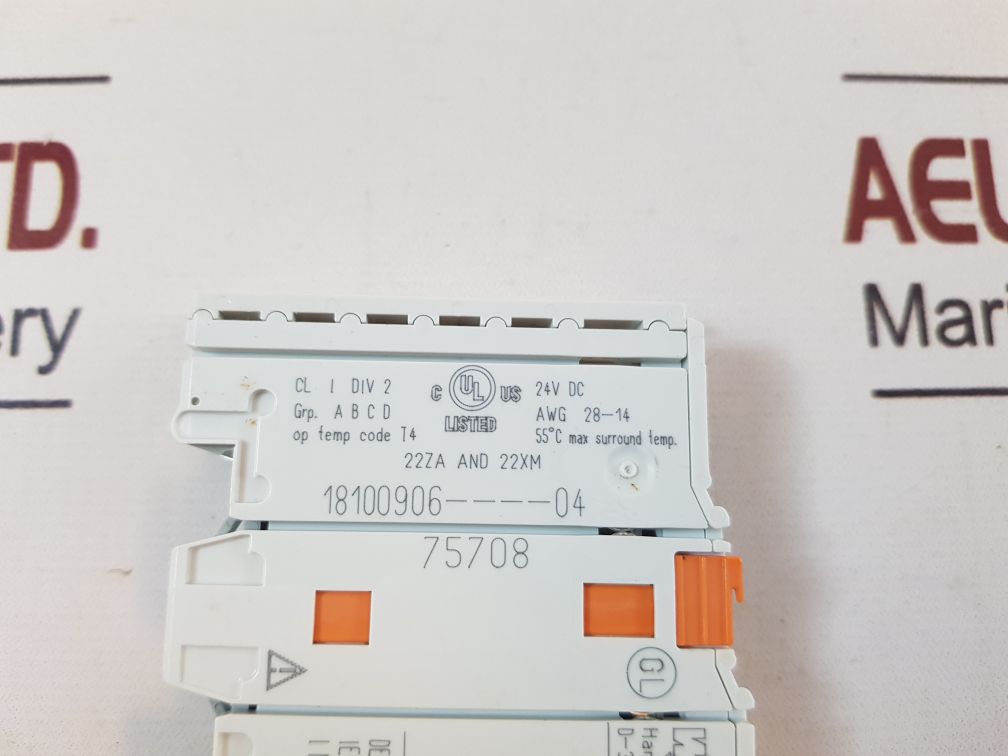

| Application | I M2/II 3 GD EX NA IIC T4, CL. I DIV 2 GRP. A B C D |

| Operating Temperature Code | T4 |

| Voltage | 24V DC |

| Wire Gauge | AWG 28-14 |

| Max. Surround Temp. | 55°C |

| Stock Numbers | 22ZA AND 22XM |

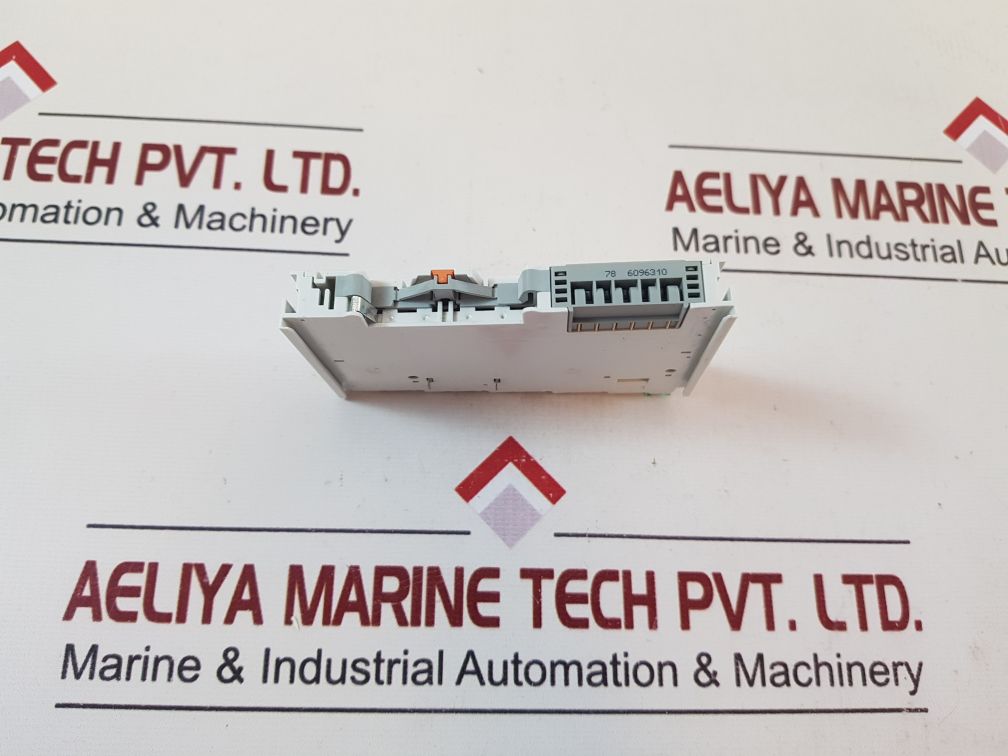

| Additional Numbers | 18100906—-04, 75708, 78 6096310, 9970-0699, 01260511808370075708 |

| Package Contents | 1 x 750-474/000-200 |

| Barcode | 4 045454 393311 |

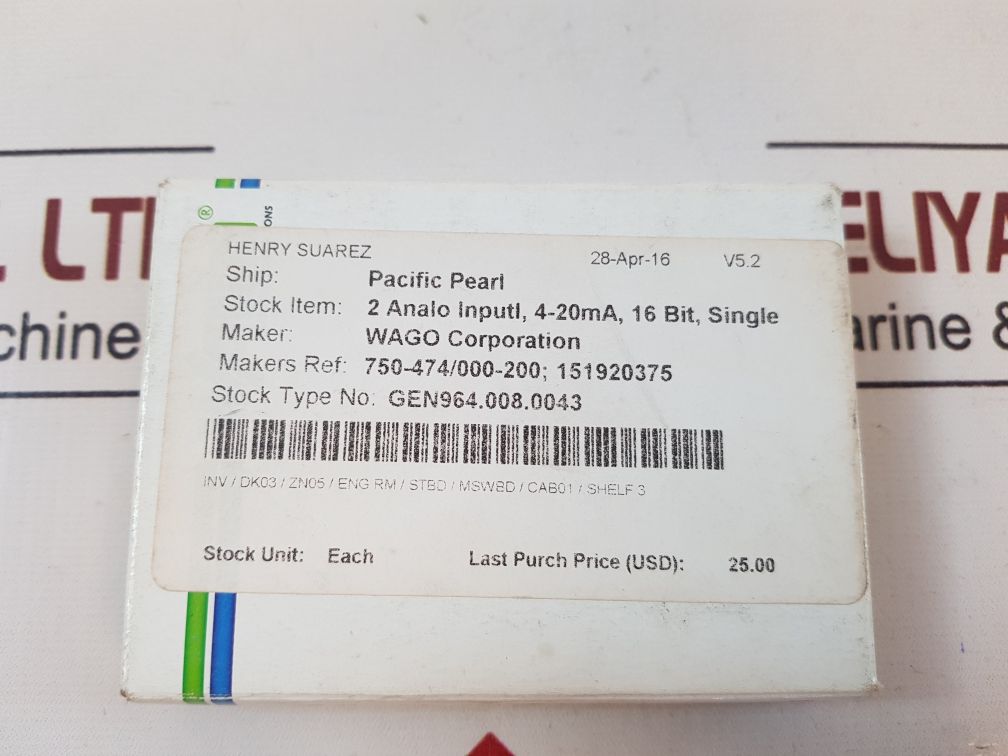

| Stock Item | 2 ANALO INPUT I, 4-20MA, 16 BIT, SINGLE |

| Makers Ref | 750-474/000-200; 151920375 |

| Stock Type No. | GEN964.008.0043 |

| Weight | 70 GM |

| Condition | NEW 3 PCS |

| Reference No. | 44591 |

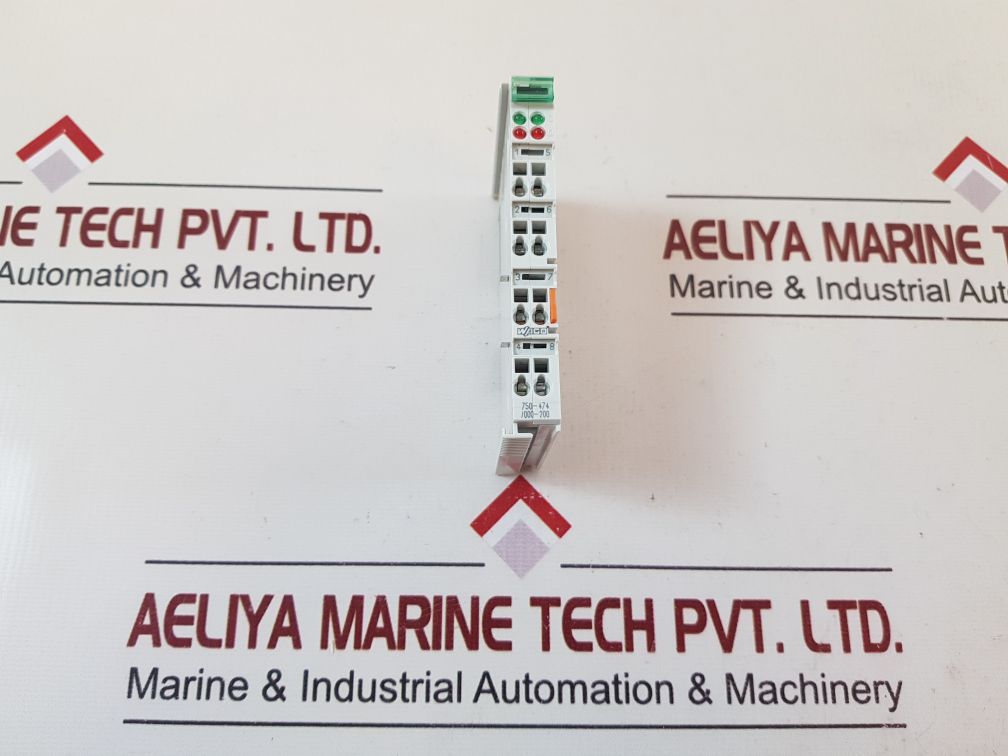

Understanding the WAGO 750-474/000-200 Module

At its core, this WAGO module is designed to handle two independent analog input signals. Whether you’re monitoring temperature, voltage, or current, the module ensures accurate measurement without sacrificing speed. Its compact form factor makes it well-suited for environments where space is at a premium, and its robust construction can endure challenging industrial conditions.

Key Features

Two Independent Channels

Each channel can be set up for various analog signals, making it flexible and scalable.

High Measurement Accuracy

The module minimizes noise interference, allowing you to capture accurate data for better control and monitoring.

Compact Footprint

The small size makes it easy to install in crowded control cabinets.

Simple Configuration

WAGO’s programming environment and documentation make setup straightforward, even for new users.

Wide Application Range

Suitable for temperature, pressure, flow, or level signals—almost any analog parameter in an industrial setup.

Why Accuracy Matters in Industrial Automation?

Optimized Process Efficiency: Accuracy in data collection can spell the difference between smooth operations and costly downtimes. The WAGO 750-474/000-200 module delivers reliable results that inform control loops and diagnostic tools. This fidelity ensures:

Optimized Process Efficiency: Better data means more accurate control, leading to resource savings and improved throughput.

Fewer Errors: High accuracy means fewer misreads, which helps you avoid sudden failures and product defects.

Consistent Quality Control: It is easier to maintain uniform product quality when your measurements are reliable.