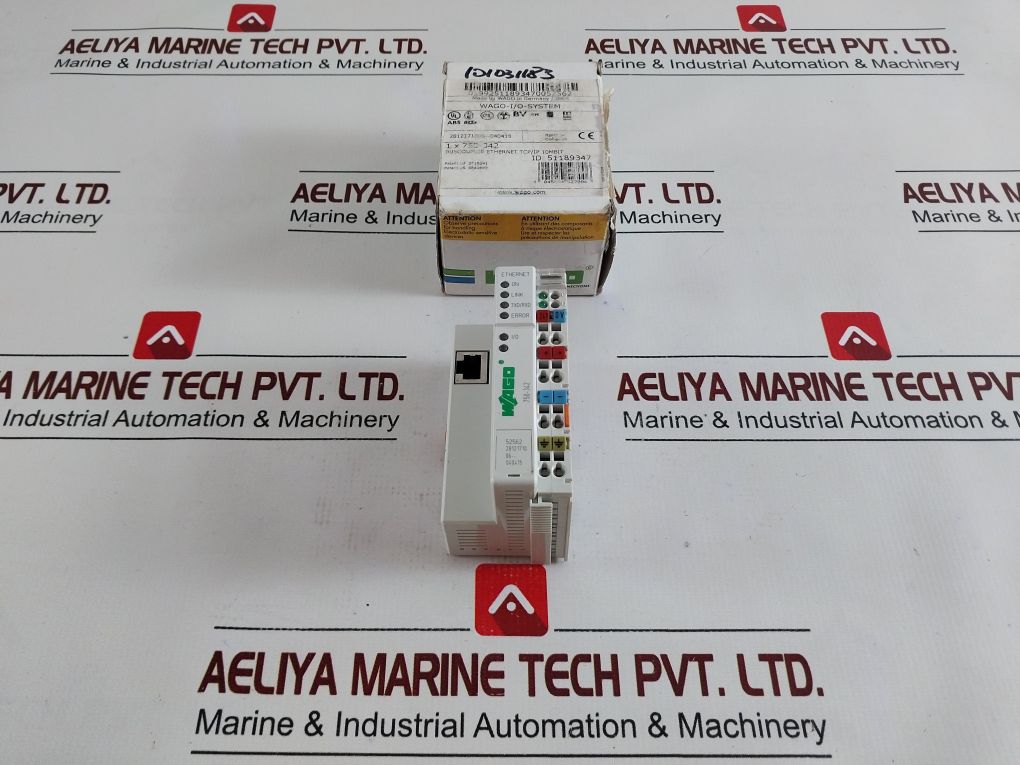

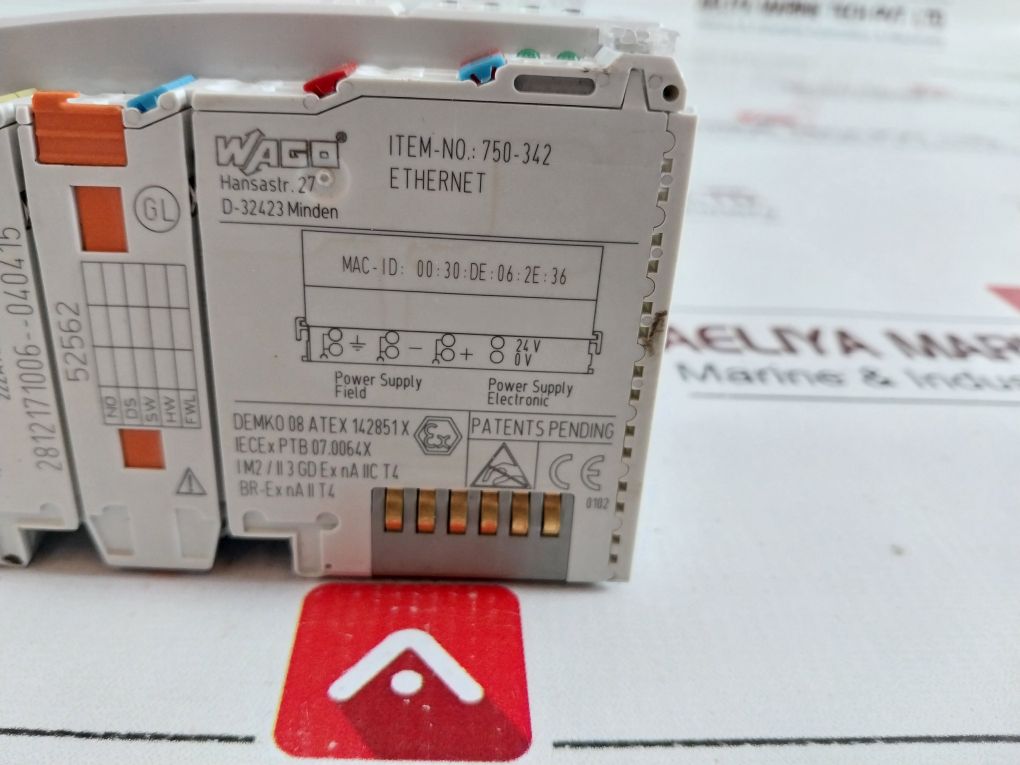

Wago 750-342 Ethernet I/o-system

Made By Wago

I/o-system

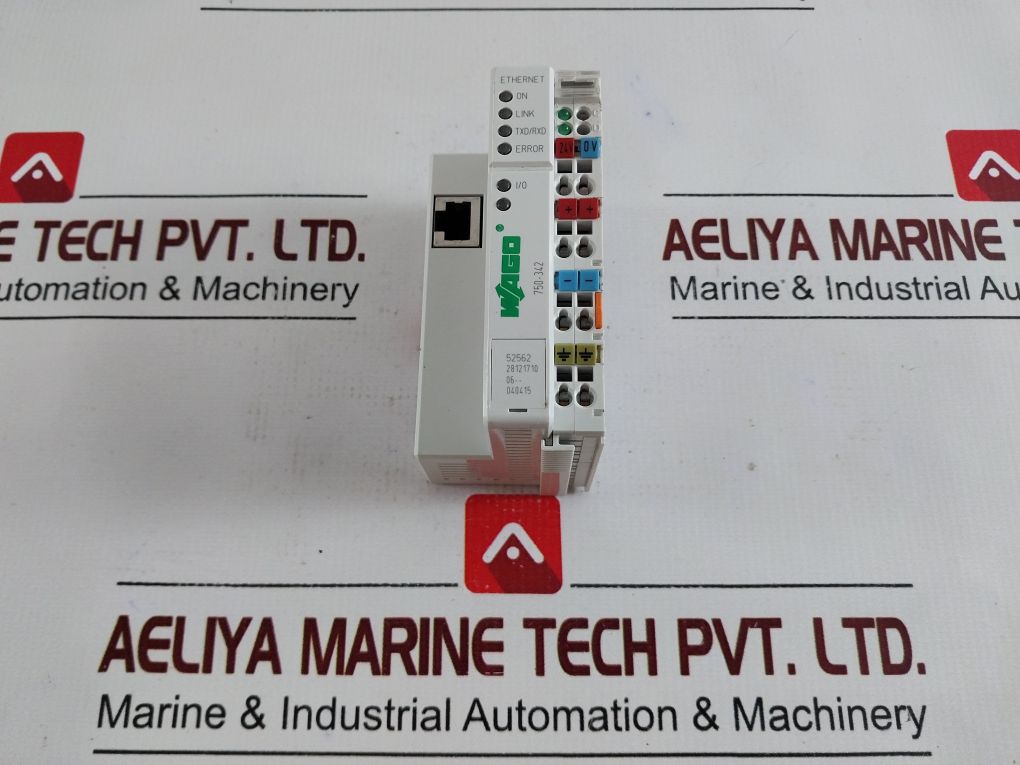

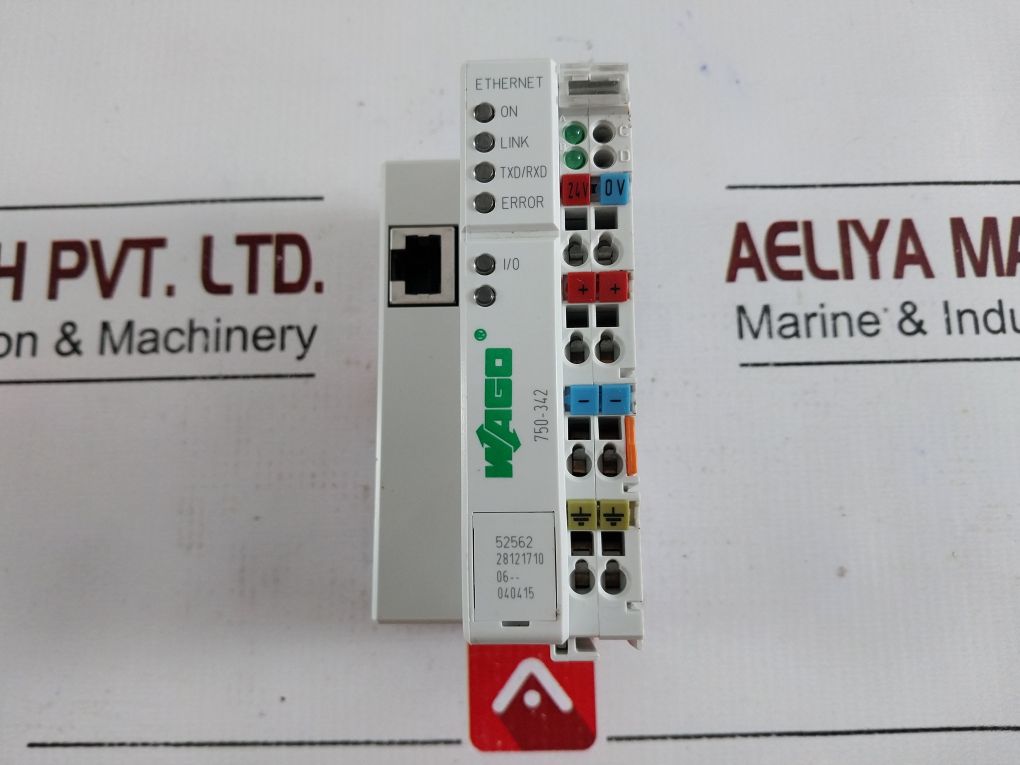

Ethernet

Item-no: 750-342

52562

28121710

06–

040415

Mac-id: 00:30:de:06:2e:36

Demko 08 Atex 142851x

Iecex Ptb 07.0064x

Im2/ii 3 Gd Ex Na Iic T4

Br-ex Na Ii T4

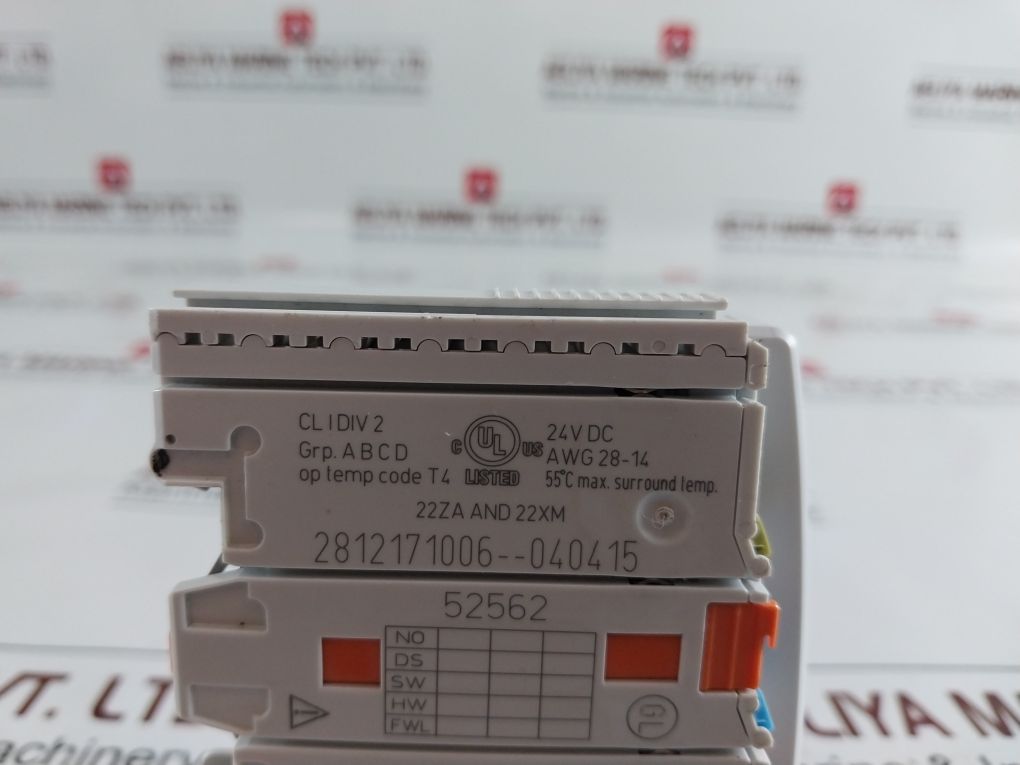

24v Dc

Awg 28-14

55°c Max. Surround Temp.

Cl I Div 2 Grp. A B C D

Op Temp Code T4

22za And 22xm

2812171006–040415

1 X 750-342

Bus Coupler Ethernet Tcp/ip 10mbit

Id: 51189347

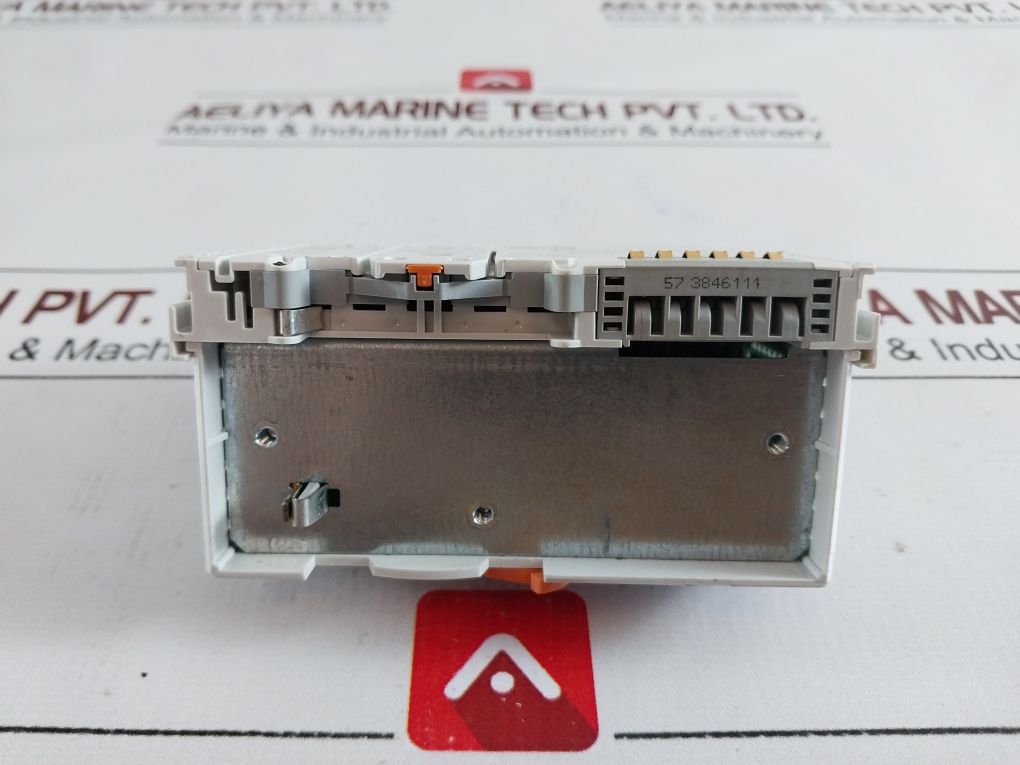

57 3846111

Made In Germany

Weight : 210 Gm

Ref No : 60593

What is Wago 750-342 Ethernet I/o-system?

The WAGO 750-342 is essentially a translator that allows industrial machines and equipment to communicate with computer networks. Imagine your factory floor as a bustling marketplace where different machines speak different languages. This coupler acts as a fluent interpreter, converting the machine language into a language computers understand.

How does it work?

- Connects machines to the network: It physically links industrial equipment to your Ethernet network.

- Translates data: It takes data from the machines and converts it into a format that can be understood by computers and software applications. It can take instructions from the network and convert them into commands for the machines.

- Enables remote monitoring and control: By connecting machines to the network, it allows you to monitor their performance, troubleshoot issues, and even control them remotely.

Key features and benefits

- Versatile: Supports multiple network protocols, making it compatible with a wide range of machines and networks.

- Easy to use: Offers user-friendly configuration options and built-in web pages for easy access to information.

- Reliable: Designed for harsh industrial environments and built to withstand fluctuations in temperature, humidity, and electrical noise.

- Efficient: Optimizes data transfer, ensuring smooth communication between machines and the network.

- Secure: Incorporates security features to protect sensitive data and prevent unauthorized access.

Applications

The 750-342 finds applications in various industries

- Manufacturing: Monitoring production lines, collecting data for quality control, and optimizing processes.

- Building Automation: Controlling HVAC systems, lighting, and security systems.

- Energy Management: Monitoring energy consumption, optimizing energy usage, and integrating renewable energy sources.

- Water and Wastewater Treatment: Monitoring water quality, controlling treatment processes, and managing distribution.