| Attribute | Vaue |

|---|---|

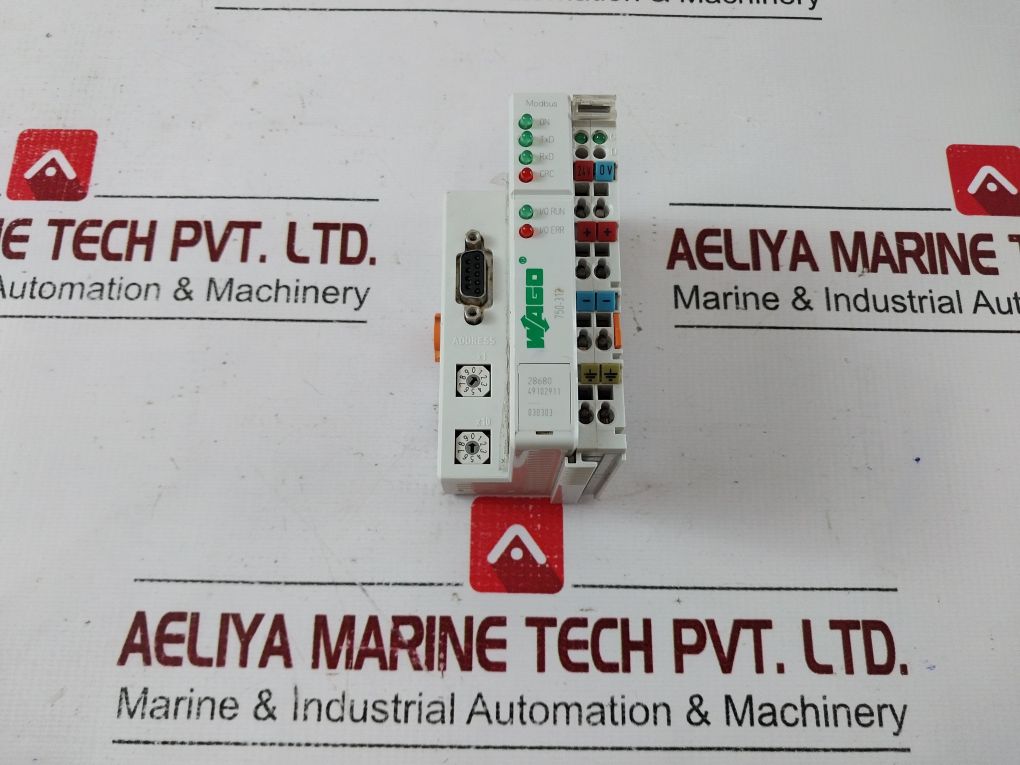

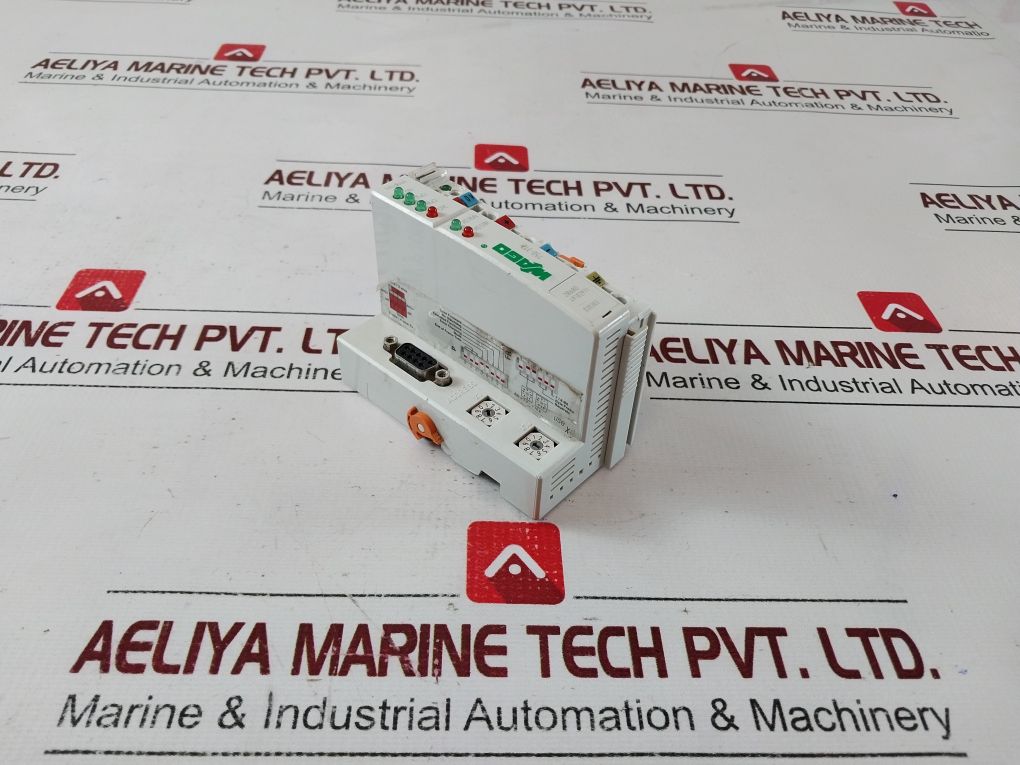

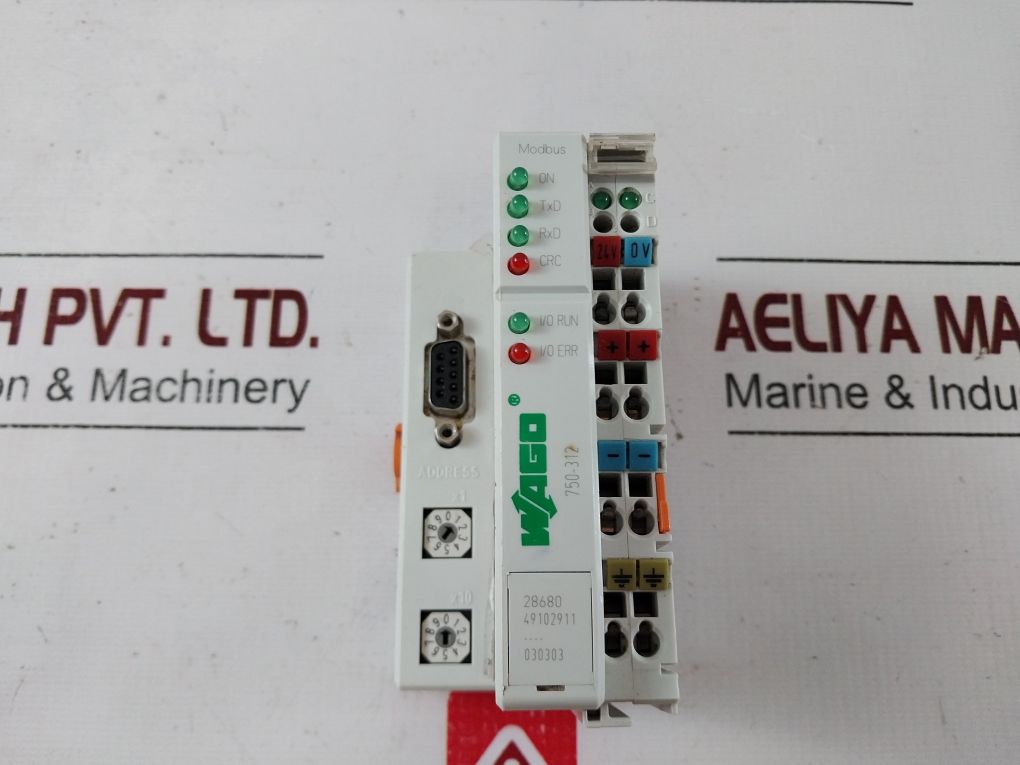

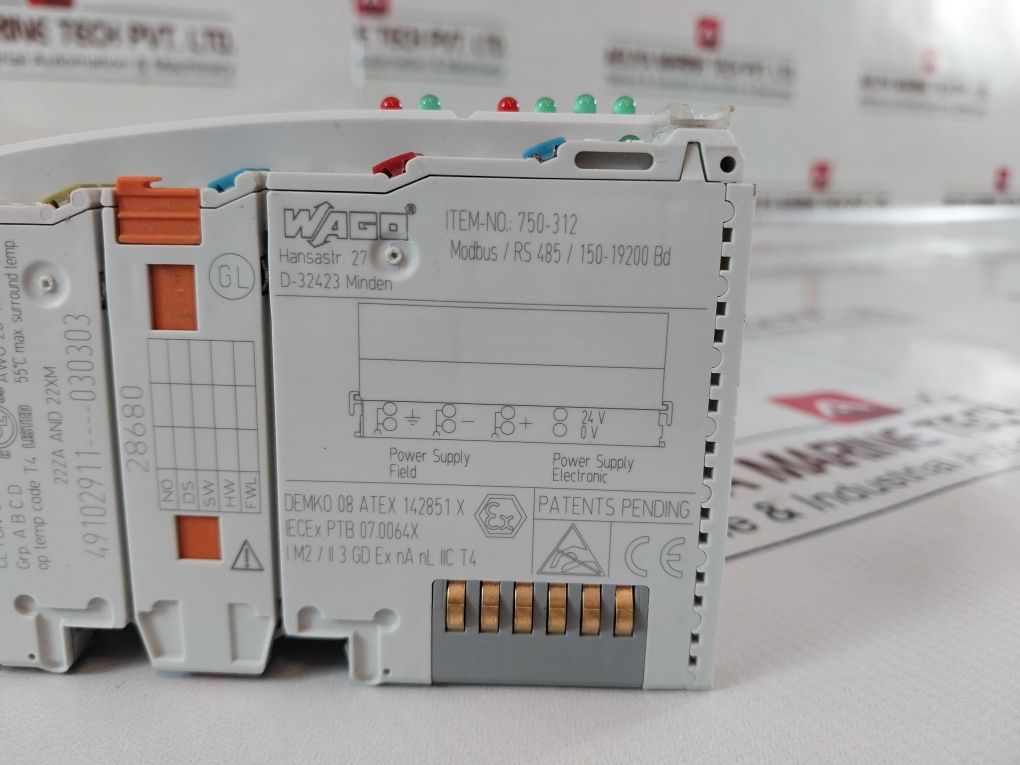

| Product | Wago 750-312 Fieldbus Coupler Modbus |

| Brand | Wago |

| Item No. | 750-312 |

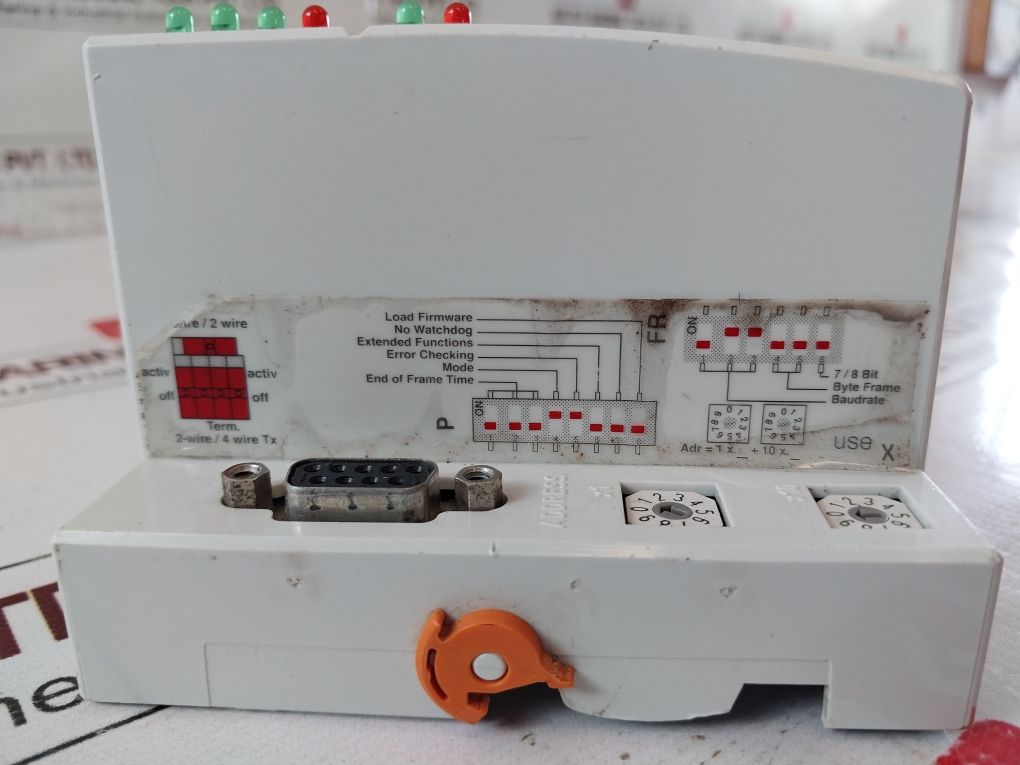

| Communication | Modbus/RS 485 / 150–19200 Bd |

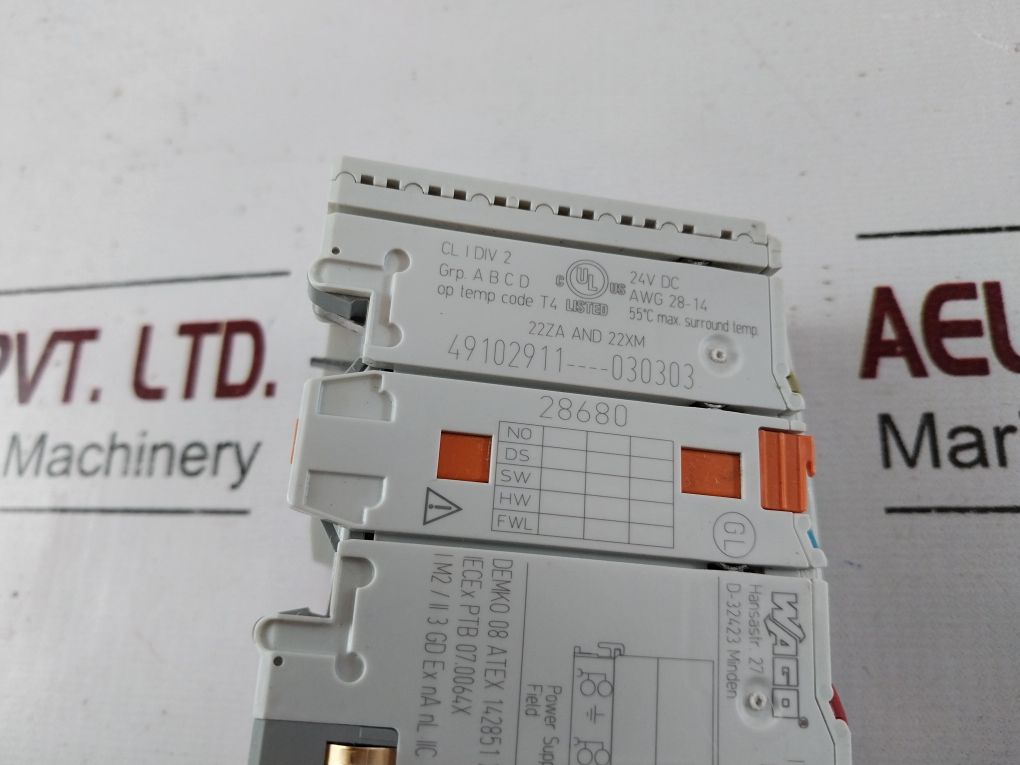

| Certifications | Demko 08 ATEX 142851 X IECEx PTB 07.0064X IM2 / II 3 GD Ex Na Nl IIC T4 Class I Div 2 Groups A, B, C, D |

| Temperature Code | T4 |

| Operating Voltage | 24V DC |

| Wire Size | AWG 28–14 |

| Max Surround Temperature | 55°C |

| Part Code | 49102911—-030303 / 28680 |

| Weight | 190 gm |

| Condition | Used (1 Pcs) |

| Ref No. | 63249 |

What is the Wago 750-312 Fieldbus Coupler Modbus?

The Wago 750-312 is a Modbus-compatible fieldbus coupler that connects modular Wago I/O nodes to higher-level controllers, including PLCs, SCADA systems, and DCS networks.

It works as a gateway, converting signals from digital or analog I/O modules to Modbus protocol messages and enabling easy communication across automation platforms.

It is designed for harsh industrial environments, with stable data exchange, efficient wiring, and expansion through additional I/O modules as an application requires.

Key Features of Wago 750-312 Fieldbus Coupler

1. Modbus RTU Compatibility

Supports Modbus RTU for easy integration with a wide range of controllers, PLCs, and industrial communication networks.

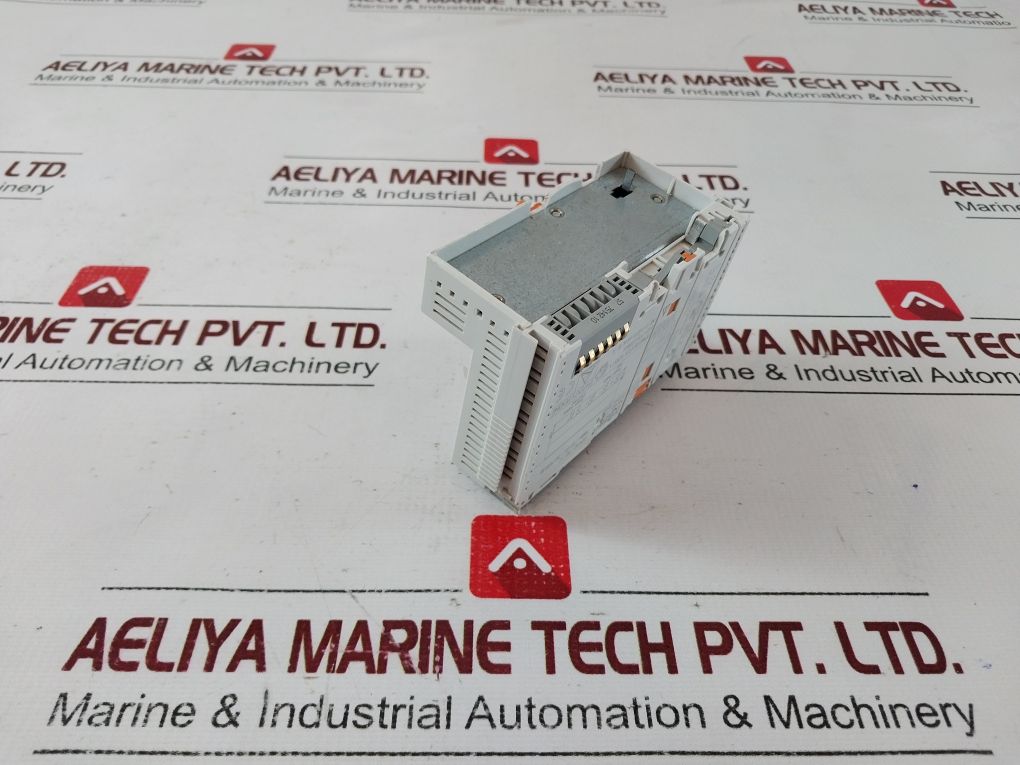

2. Modular I/O Architecture

Compatible with WAGO 750-series I/O modules to provide the ability to build customized I/O stations.

3. Rugged Industrial Design

Engineered to withstand vibration, temperature variations, and demanding operating environments.

4. Easy Configuration and Setup

Easy addressing and parameter configuration allow for fast and user-friendly installation.

5. Quick and Sure Communication

Provides strong data exchange with minimum latency, guaranteeing real-time visibility and control.

6. Diagnostic LEDs

Provides quick indication of communication status, power, and system health for ease of troubleshooting.

7. Flexible Network Integration

Designed to operate as a communication gateway for distributed field devices in complex automation networks.

8. Low Power Consumption

It saves energy by an effective design without reducing performance.

Applications of the Wago 750-312 Fieldbus Coupler

The Wago 750-312 can be used in an extremely wide range of industries and automation tasks:

1. Industrial Automation Systems

Used in machinery control, automation of factories, and distributed management of I/O.

2. Marine and Offshore Automation

Suitable for ship control systems, engine rooms, monitoring panels, and remote operation systems.

3. Process Industries

Suitable for oil & gas, water treatment, pharmaceuticals, chemical plants, and food processing.

4. Building Automation

The integration of HVAC systems, lighting control, and energy management platforms.

5. SCADA and Monitoring Networks

Serves as the communication bridge for data acquisition and remote monitoring.

6. Renewable Energy Systems

Utilized in solar farms, wind turbines, and power distribution networks to monitor field devices.

7. Machinery and Equipment Upgrades

Ideal for retrofitting older systems that require modern Modbus communication capabilities.

Why Choose the Wago 750-312 Fieldbus Coupler?

1. Proven Reliability

Wago has become synonymous with durable and high-quality automation components, offering stable performance to many customers worldwide.

2. Compatibility with Multiple I/O Types

Supports analog, digital, and specialty I/O modules that provide complete design flexibility for any project.

3. Simplified Wiring and Maintenance

The modular layout reduces wiring complexity and allows easy replacement or expansion.

4. Cost-Effective Automation Solution

Provides high functionality at an affordable cost, making it ideal for budget-sensitive industrial upgrades.

5. Improves System Scalability

Allows your automation setup to scale up as operational demands increase.

6. Designed for Harsh Environments

Suitable for marine, industrial, and high-vibration areas where reliable communication is essential.

7. Ideal for distributed field applications

Perfect for distributed control systems, remote panels, and field installations requiring stable Modbus communication.