| Attribute | value |

|---|---|

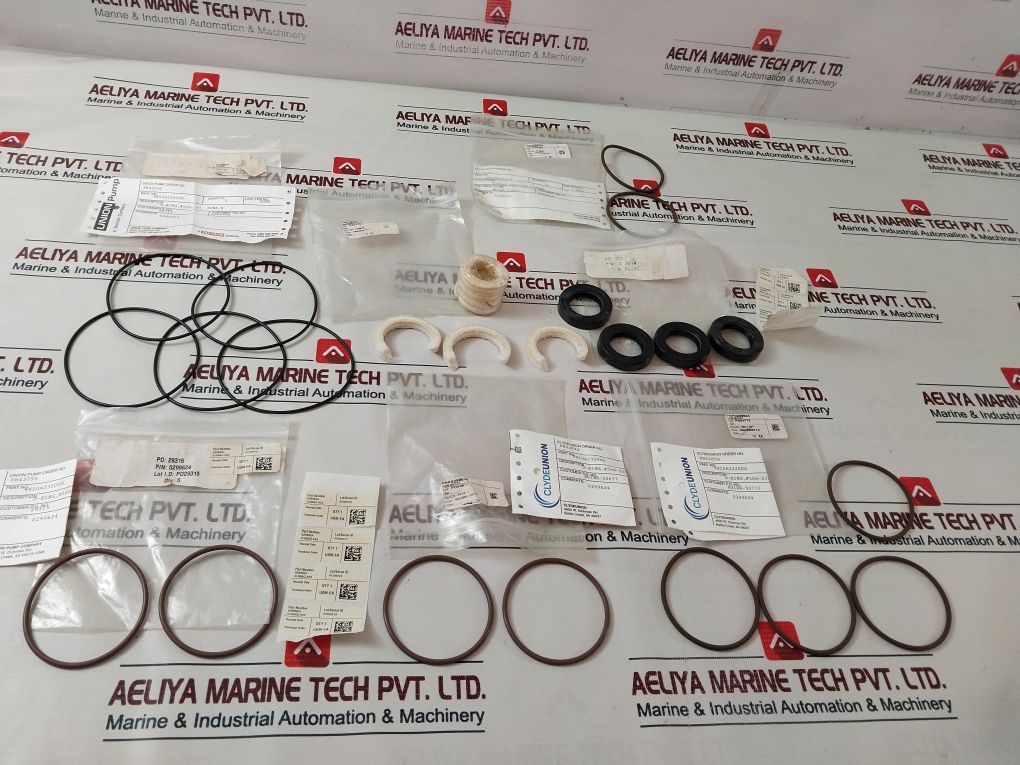

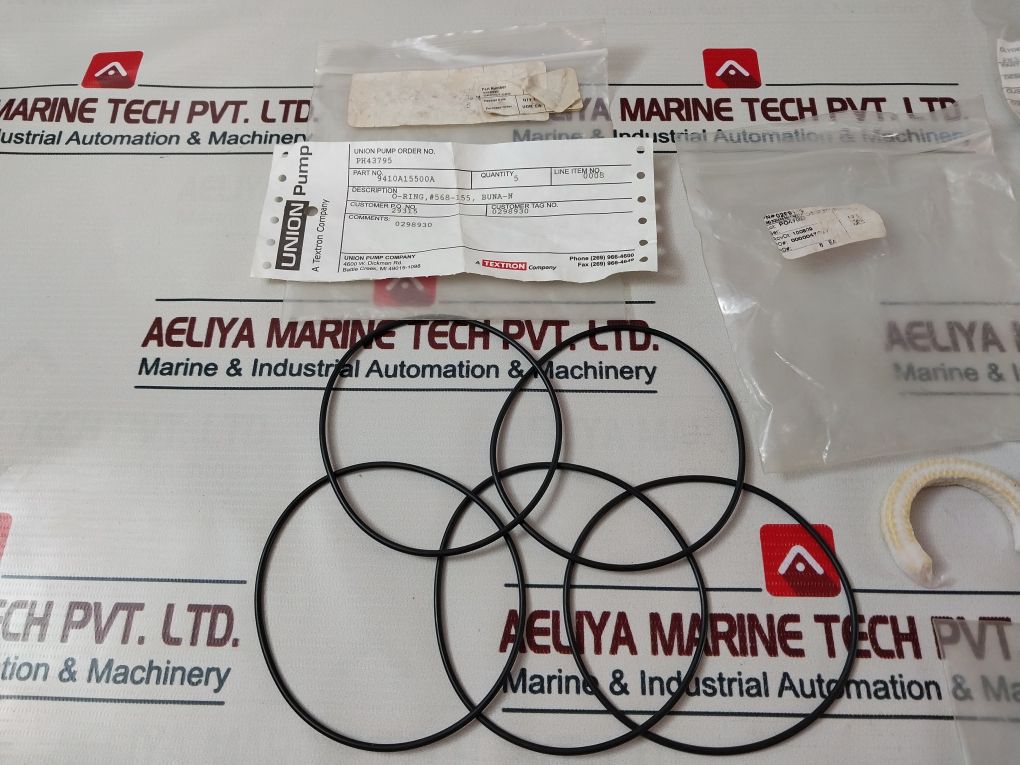

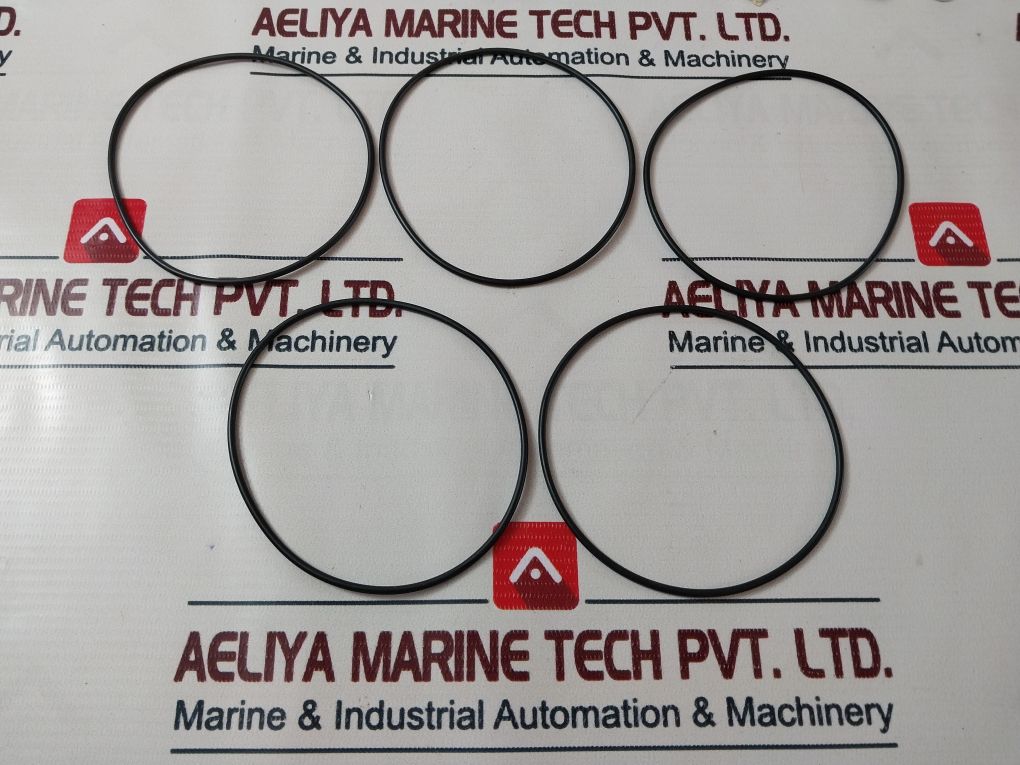

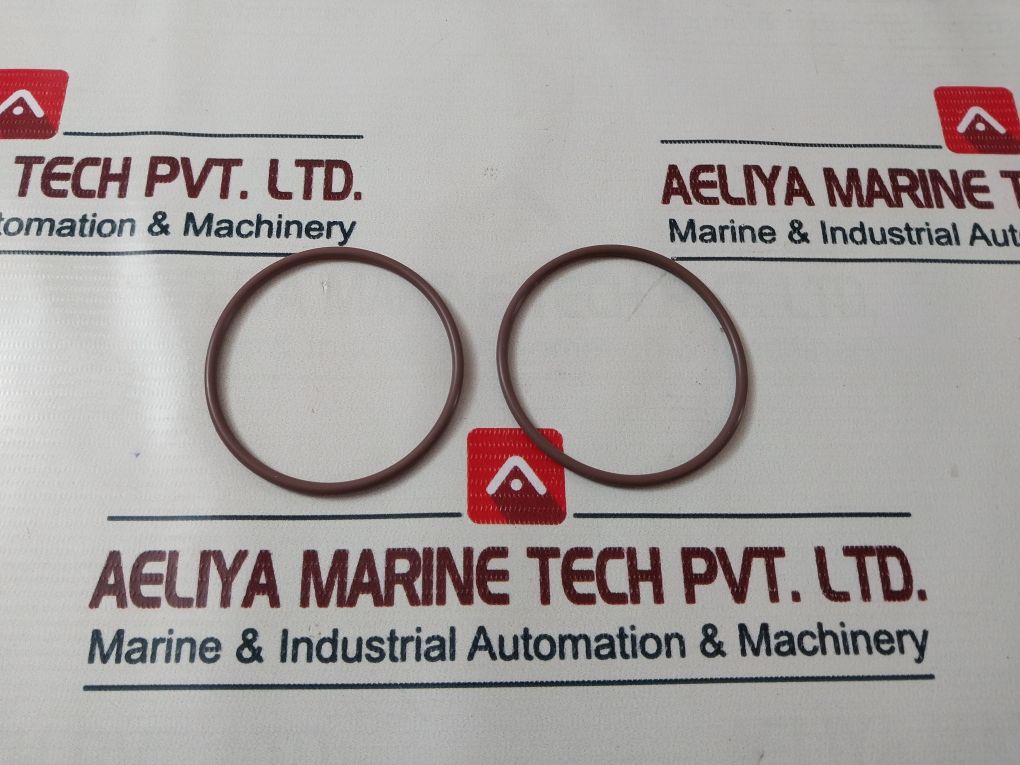

| Product Name | Viton 568-232 O-ring |

| Brand | Viton |

| Manufacturer | Union Pump Company, A Textron Company |

| Associated Brand | Clydeunion |

| Order No (1) | PH43795 |

| Part No | 9410A23200G |

| Description | O-ring, #568-232 |

| Order No (2) | PH55048 |

| Order No (3) | PH52859 |

| Part Number/PN # | 0299624 |

| Seal Type | Seal Oil C |

| Part Number (Alternate) | 0298810 |

| Weight | 330 GM |

| Ref No | 73958 |

What is the Viton 568-232 O-Ring?

The Viton 568-232 O-Ring is a fluorocarbon rubber (FKM) sealing component precision-engineered under the trade name Viton. It is part of the AS568 standard series of O-rings, with the -232 size engineered to fit into grooves where consistent sealing is imperative.

This O-ring is widely used across several industries because of its resistance to a broad spectrum of chemicals, high working temperatures, and compressive stress retention, making it perfect for hostile sealing conditions.

Features of Viton 568-232 O-Ring

Excellent Chemical Resistance

Viton O-rings resist oils, fuels, lubricants, and most mineral acids. The 568-232 type functions well in contact with hydrocarbons and aggressive chemicals that deteriorate normal rubber seals.

High-Temperature Performance

Works well in an extensive temperature range of -20°C to +200°C (shortly up to +250°C), the reason why it’s perfect for engine systems, pumps, and valves under thermal stress.

Durability and Life

Fluorocarbon content provides high resistance, minimal compression set, and superior wear resistance. This translates to fewer replacements, reduced downtime, and long-term cost savings.

Compliance to Standard Sizing

Being part of the AS568 series, it suits perfectly in standardized grooves, easier to replace and cross-brand compatible.

Low Gas Permeation

Ideal for vacuum and pressurized applications, preventing leakage and reduction in performance over time.

Uses of Viton 568-232 O-Ring

Owing to its tough nature, the Viton 568-232 O-Ring finds application in:

Automotive and Diesel Engines – sealing oil, fuel, and coolant systems.

Chemical Processing Plants – prevention of safety hazards due to exposure to harsh chemicals.

Hydraulic and Pneumatic Systems – withstanding breakdown of fluids over time.

Marine Applications – withstanding integrity in saltwater and oil-based environments.

Aerospace and Aviation – stringent performance demands in fuel systems.

Why Select Viton Instead of Conventional Rubber?

Although conventional rubber seals (such as nitrile or EPDM) are appropriate for general sealing services, they soften rapidly when exposed to heat, oil, and chemicals. However, Viton has the ability to retain its shape and functionality, even during harsh working conditions. The size 568-232 provides an ideal combination of compatibility and versatility for equipment builders and maintenance technicians.

Reviews

There are no reviews yet.