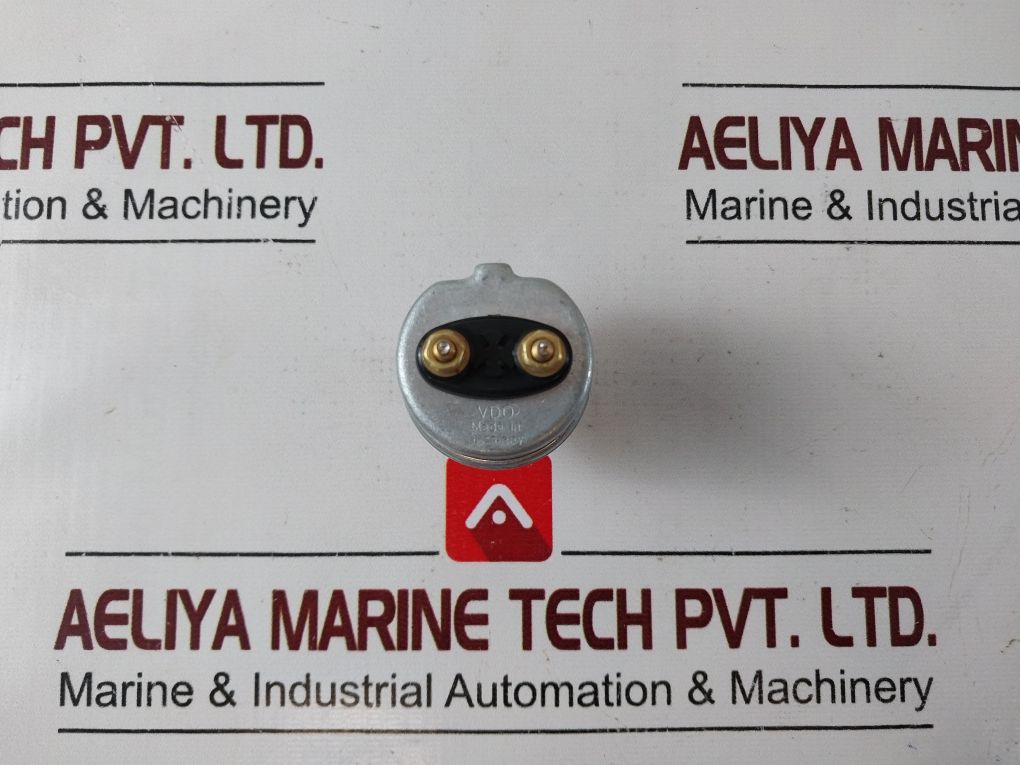

Vdo 38/1 Pressure Sensor

Vdo

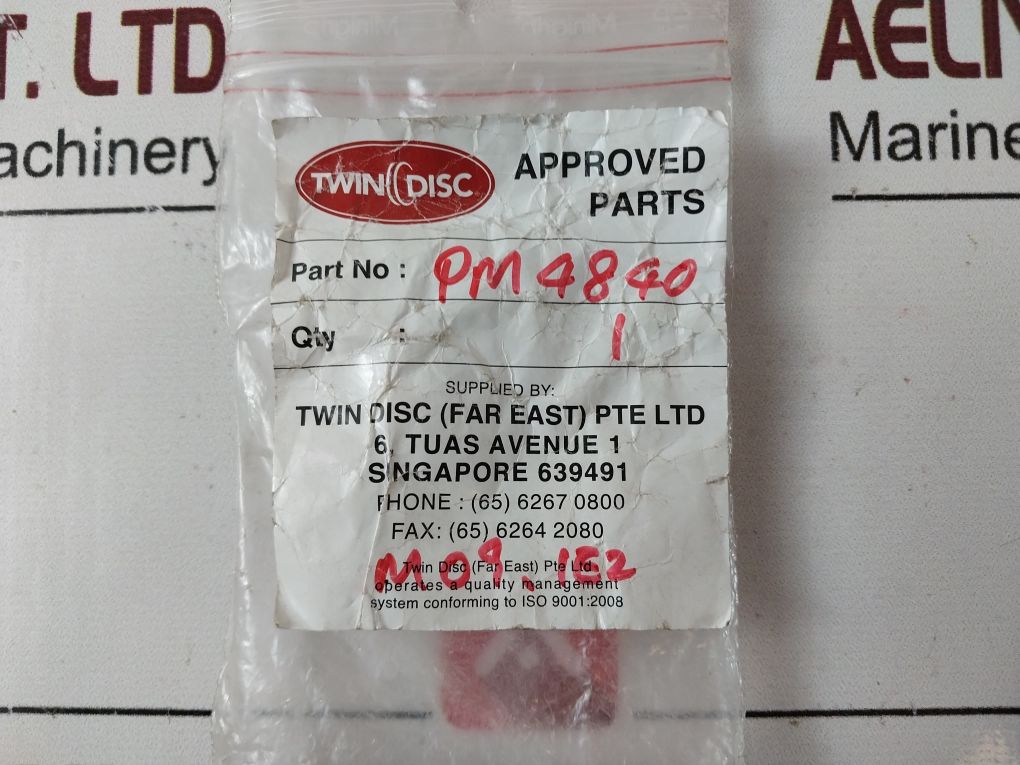

Twin Disc

Part No: Pm4840

38/1

1017/10.17

0/5 Bar

Made In Germany

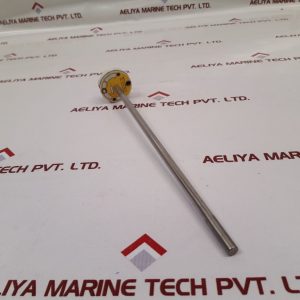

Weight : 140 Gm

Condition : New 1 Pcs

Ref No : 62136

This sensor is paramount in pressure limiting in several systems to ensure that performance is optimum, safety is assured, and service life of all equipment is guaranteed.

VDO 38/1 Pressure Sensor

The VDO 38/1 Pressure Sensor has been built to be highly sensitive, robust, and measure pressure with a great degree of accuracy. From automotive and industrial to marine-the most unforgiving environments have been engineered into this sensor to deliver reliable readings every time.

Key Features of the VDO 38/1 Pressure Sensor

High Accuracy: The VDO 38/1 Pressure Sensor stands out with extremely high accuracy. They measure pressure with very high precision that is required for smooth operations in numerous systems. With such an exact measurement, any fluctuation that may sometimes indicate problems can be possible to detect.

Durability and Robustness: VDO 38/1 is made from the finest materials and has been designed to meet adverse working conditions. It operates in a wide temperature range, resists extreme vibrations, and presents no problems in running under extreme pressure differences. Thus, it can be used in heavy industries where durability is the keyword.

Some of the wide application areas include monitoring oil pressure in engines, hydraulic systems, and industrial machinery, among others. The pressure sensor VDO 38/1 finds wide applicability in numerous industries. This versatility makes it a benchmark solution for both engineers and technicians.

Compact Design: Considering the high power and precision involved, the VDO 38/1 remains compact for easy fitment into systems where space can be an issue. The reduced size also enables more flexibility in installation without sacrifice in performance.

Long-Lasting Performance: The VDO 38/1 Pressure Sensor is built to ensure long-term performance because of its robust construction and employment of high-quality components. Fewer replacements reduce total hours of downtime, hence lowering overall maintenance costs over a period of time, which strengthens overall efficiency.

Applications of the VDO 38/1 Pressure Sensor

The VDO 38/1 Pressure Sensor is designed for various applications across various sectors:

Automotive Industry: In vehicles, pressure sensors are highly critical to observe engine oil pressure for the smooth running and efficiency of the engine. The VDO 38/1 assumes a great role in preventing engine failure because it provides early warning signals in case the pressure level is not at its optimal state.

Marine Field: Smooth functioning of marine engines and hydraulic systems relies on precise pressure monitoring. The VDO 38/1 sensor also finds application in ships and boats to maintain the operability of critical systems without any failure during operation at sea.

Industrial Equipment: It is very important in factories and industrial setups to maintain exact pressure levels of hydraulic systems, pumps, and compressors for safety and efficiency in operations. The VDO 38/1 makes sure that any deviation from this pressure is always noticed on time and corrective measure sought and done on time.

HVAC Systems: Pressure monitoring is also needed in HVAC systems for the regulation of airflow and fluids. The VDO 38/1 sensor maintains pressure levels within the optimum range to prevent system failure and ensure energy efficiency.

Why Choose the VDO 38/1 Pressure Sensor?

Proper selection of pressure sensors is very important for ensuring safety and efficiency within your systems. Indeed, the choice of the VDO 38/1 Pressure Sensor will be attributed to the following features:

Reliability: It works under the most extreme conditions without ever showing a reduction in performance and ensures that your systems are up and running.

Ease of Installation: Compact in size, this makes it conveniently installed in a system whether for retrofit or new installation.

Cost-effectiveness due to durability and long life, the VDO 38/1 reduces frequent replacements, hence making the operation cost-effective and minimizing system downtime.

VDO 38/1 Pressure Sensor Maintenance and Care

For your VDO 38/1 Pressure Sensor to always work within normal parameters, below are steps on how best you can conduct maintenance:

Routine Check: Routine inspection of the sensor for any evidence of wear and tear. Replace worn-out sensors without delay in order not to experience system failures.

Cleaning: Keep the sensor clean from dust and debris accumulation, especially in harsh environments. This will ensure accuracy in sensor readings apart from elongating the life of the sensor.

Calibration: As time goes on with use, sensors will drift out of calibration. Regular calibration will maintain the accuracy of the sensor at its high level.