| Attribute | Value |

|---|---|

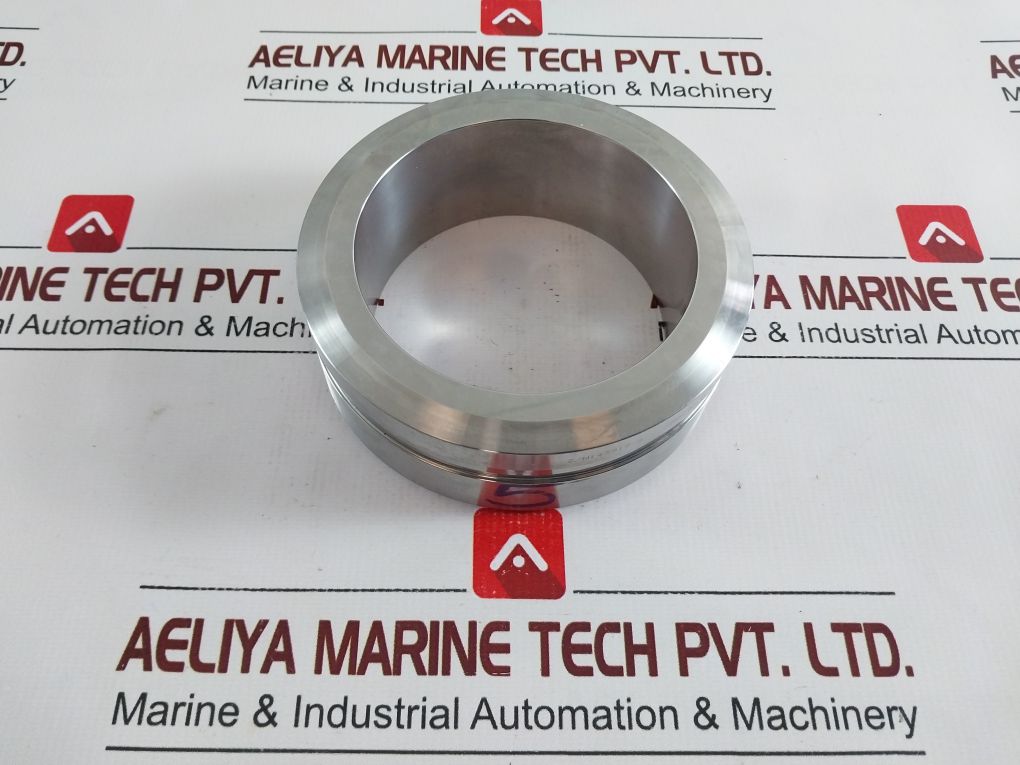

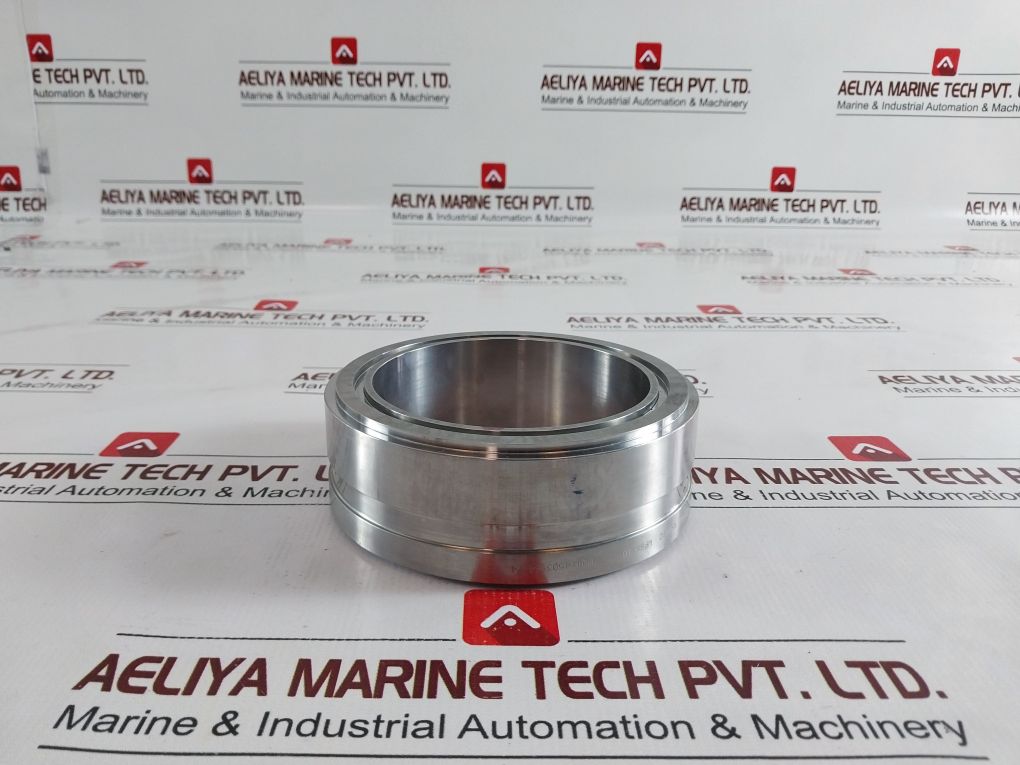

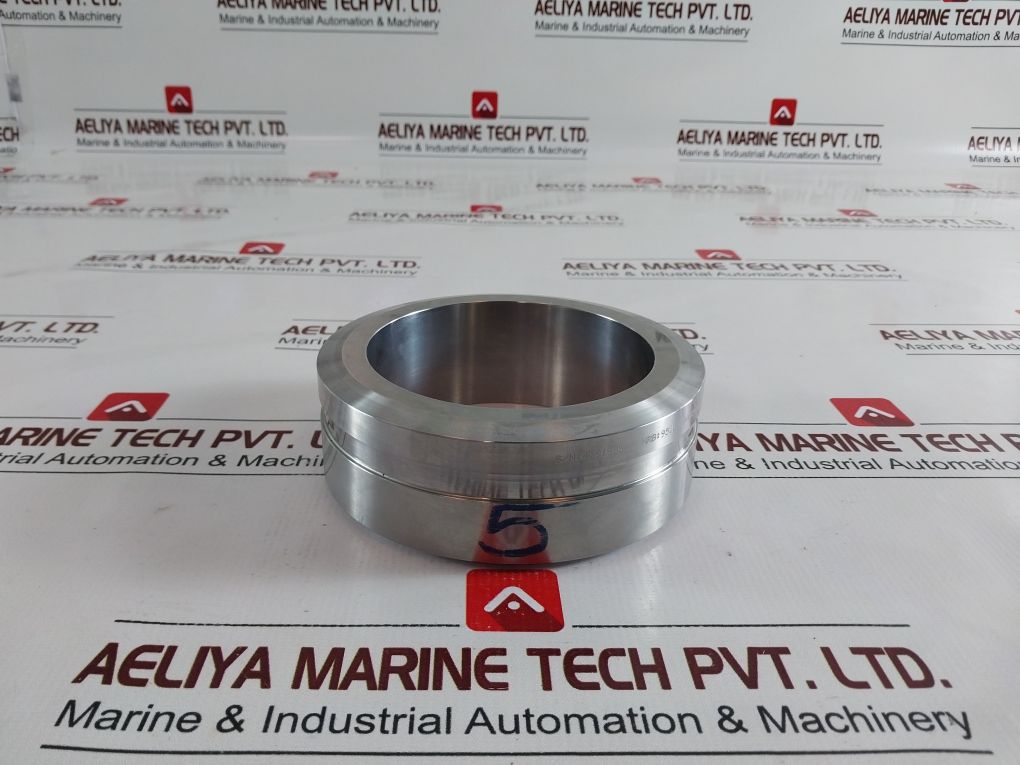

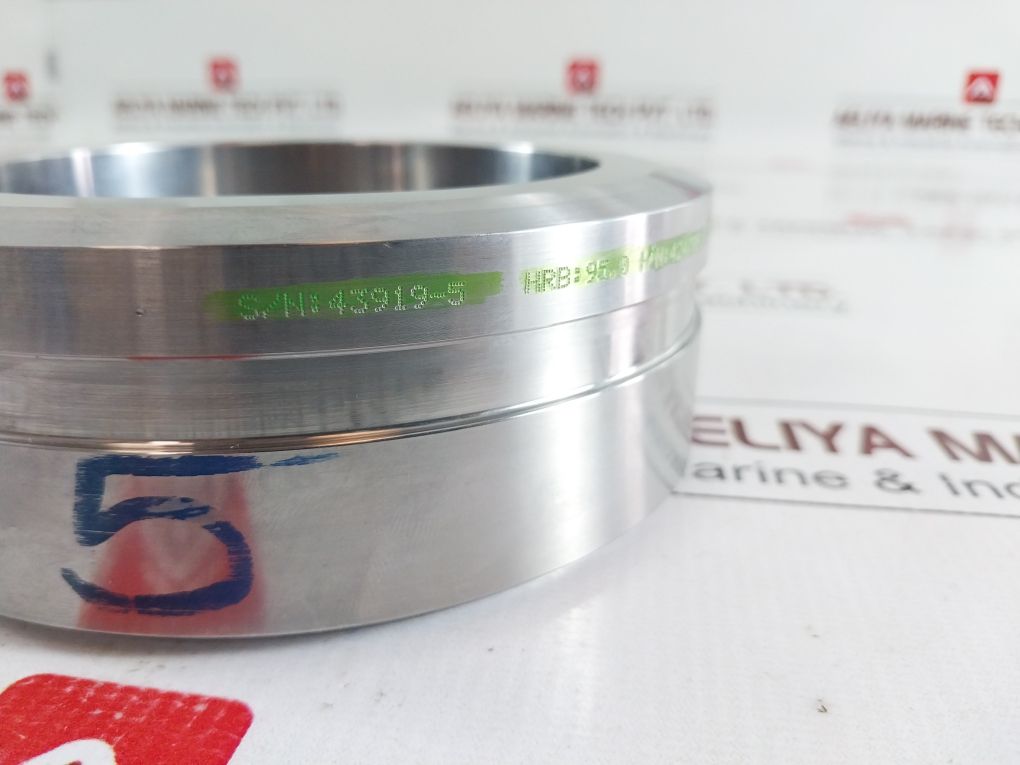

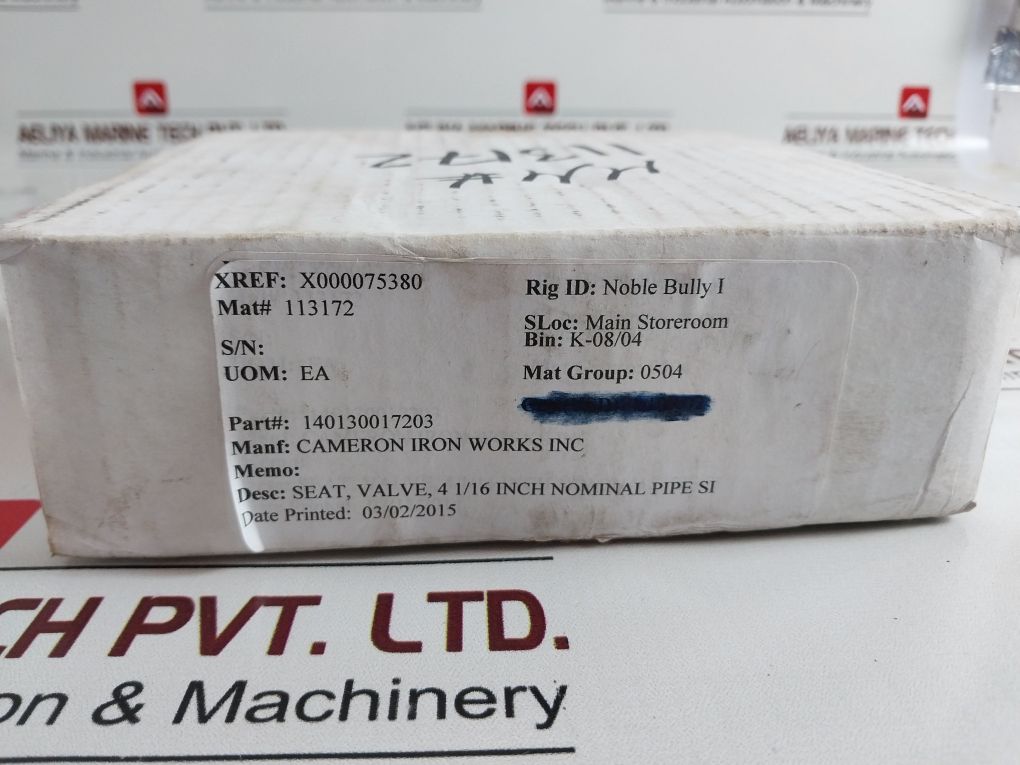

| Product Name | Tribocor 140130-01-72-03 Valve Seat |

| Brand | Tribocor Technologies Inc. |

| Manufacturer | Cameron Iron Works Inc. |

| HRB | 95.0 |

| H/N | 424785 |

| P/N | 140130-01-72-03 |

| Revision | 02 |

| WPS | 110 |

| Description | Seat, Valve, 4 1/16 Inch Nominal Pipe Si |

| XREF | X000075380 |

| Material Number | 113172 |

| Weight | 2.470 Kg |

| Condition | New (2 Pcs) |

| Ref No | 61196 |

What is the Tribocor 140130-01-72-03 Valve Seat?

The Tribocor 140130-01-72-03 Valve Seat is a precision-engineered seating component that provides tight sealing in valves operating in industrial, process, and marine applications. Made from high-strength materials with advanced coating technologies, it ensures extended life expectancy even in operational environments involving abrasive fluids, high pressures, or corrosive media.

Valve seats play a critical role in flow control, providing a proper seal surface for the valve plug, ball, or disc. This Tribocor model is unique because of its design accuracy, surface finish, and capability for maintaining seal functionality after long operation.

Key Features of Tribocor 140130-01-72-03 Valve Seat

1. High Wear Resistance

The advanced material composition used to manufacture Tribocor seats allows them to resist friction, abrasion, and high cycle counts. This extends the lives of valves even under harsh operating conditions.

2. Corrosion-Resistant Construction

Model 140130-01-72-03 resists rust, chemical attack, and moisture, making it suitable for marine and chemical environments where the components are exposed to corrosive agents.

3. Precision Machining

Each valve seat is manufactured within tight tolerances to meet for a perfect fit. This geometry provides increased sealing reliability and reduces leakage.

4. Thermal Stability

It maintains structural integrity during fluctuating temperature ranges without distortion, with consistency in flow control.

5. Low Maintenance Design

Its robust build reduces the frequency of replacements and repair cycles, hence it is cost-effective for long-term use in an industrial setting.

6. Compatibility With Several Types of Valves

Designed to integrate with industrial valves such as control valves, safety valves, shut-off valves, and process valves.

Applications of the Tribocor 140130-01-72-03 Valve Seat

The Tribocor valve seat lends itself to versatility for many industries, especially in those areas where reliability and precision are of utmost importance.

1. Marine Mechanical Systems

Used in pumps, compressors, and fluid control systems on ships and offshore platforms.

2. Oil & Gas Industries

Ideal applications are high-pressure valves applied in drilling systems, refineries, and petrochemical plants.

3. Chemical Processing Plants

Suitable for valves handling corrosive fluids or aggressive chemicals.

4. Power Generation Units

Applied in steam, water, and cooling systems where durable seal components are called for.

5. Industrial Manufacturing Machinery

Applied in pneumatic, hydraulic, and automated flow control systems where consistent valve performance is required.

6. Water Treatment & Filtration Plants

Ensures dependable operation in systems subjected to widely ranging pressures and contaminants.

Why Choose the Tribocor 140130-01-72-03 Valve Seat?

1. Proven Durability

This valve seat offers a long service life to minimize plant downtime and the expenditure associated with frequent replacements.

2. Better Sealing Performance

Precision-engineered surface for minimal leakage and optimal flow control.

3. Quality of Tribocor You Can Trust

Tribocor stands for high-performance industrial components manufactured according to uniformly high standards of quality.

4. Ideal for Harsh Environments

It is reliable for marine, offshore, and chemical sectors because of its resistance to corrosion, wear, and temperature variation.

5. Cost-Efficient Over Time

Although built with advanced materials, the lower maintenance needs and long life provide excellent value.

6. Supports Operational Safety

Leak-tight performance decreases risks by protecting critical systems from operational hazards.