| Attribute | Value |

|---|---|

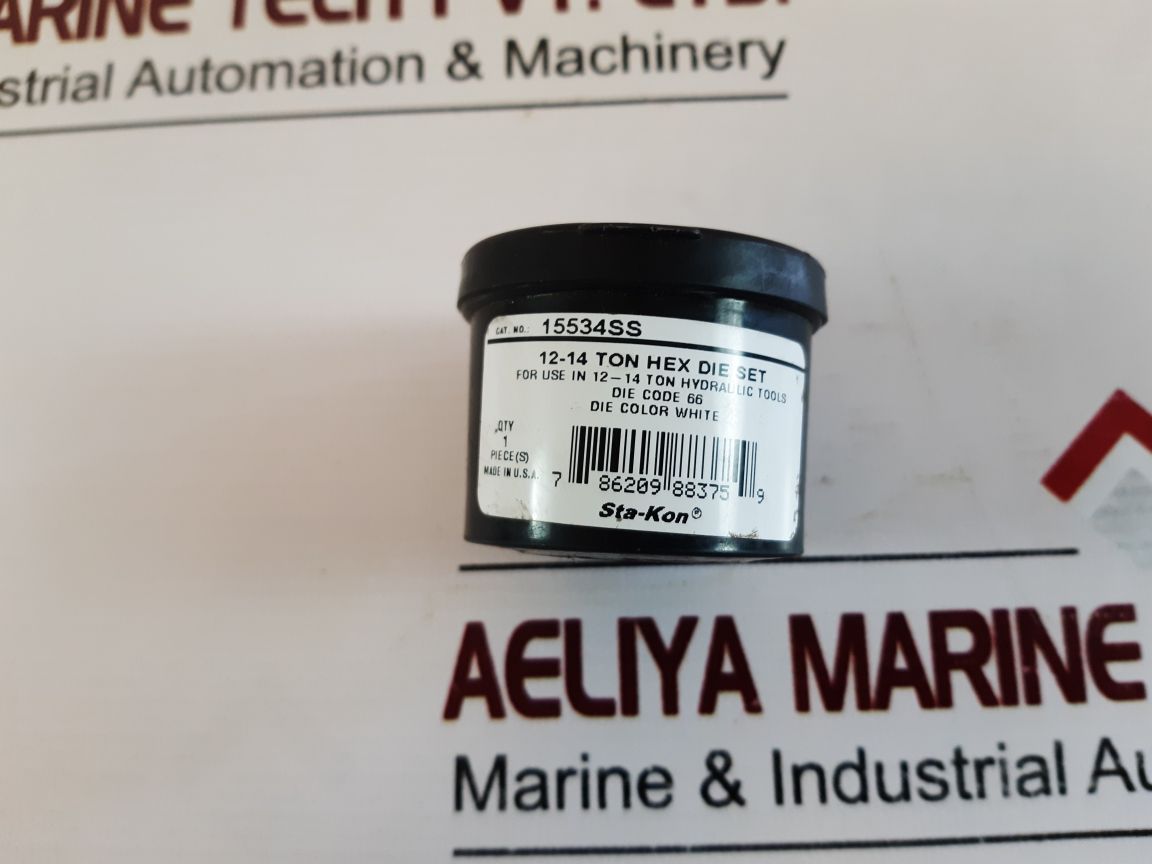

| Product Name | Thomas & Betts 15534SS Connector Die |

| Brand | T & B / Thomas & Betts / Sta-kon |

| Model / Part No. | 15534SS / 66 |

| Category | Hex Die Set |

| Capacity | 12–14 Ton |

| Application | For use in 12–14 ton hydraulic tools |

| Die Code | 66 |

| Die Color | White |

| Barcode | 7 86209 88375 9 |

| Country of Origin | Made in U.S.A. |

| Weight | 230 gm |

| Condition | New (1 Pc) |

| Reference No. | 57619 |

What is the Thomas & Betts 15534SS Connector Die?

The Thomas & Betts 15534SS Connector Die is a specialty stainless-steel crimping die used with compatible T&B hydraulic or mechanical crimping tools. This produces a precise and secure crimp in various styles of electrical lugs, terminals, and connectors for strong electrical continuity and mechanical holding force.

Built for heavy-duty environments, it maintains consistent performance even under demanding conditions such as continuous usage, high-vibration areas, or corrosive atmospheres found in marine and industrial setups.

Key Features of the Thomas & Betts 15534SS Connector Die

1. Stainless Steel Construction

The 15534SS die uses high-grade stainless steel which resists corrosion, wear, and deformation. It is ideal for harsh industrial and marine environments.

2. Precision-Engineered Crimp Profile

The die creates uniform and secure crimps with excellent conductivity, minimizing the chances of failure caused by loose or improper terminations.

3. High Durability for Long Life

Its sturdy build means that it can be used for extended periods with minimal wear, thereby reducing replacement costs and enhancing productivity.

4. Compatible with numerous crimping tooling options

The 15534SS is designed to fit Thomas & Betts OEM tools and selected industry-standard crimpers, offering flexibility and ease of integration.

5. Reliable Performance in Demanding Conditions

Whether applied to high-load cables, marine wiring, or industrial control panels, this die provides consistent results.

6. Easy Identification

Stamped markings provide for quick identification of die sizes, thereby minimizing occurrences of errors during installations.

Applications of the Thomas & Betts 15534SS Connector Die

The die finds wide applications in many industries that demand high-quality cable terminations:

✔ Industrial Electrical Panels

For crimping lugs and connectors inside MCCs, PLC panels, power cabinets, and control systems.

✔ Marine & Offshore Installations

Its build of corrosion-resistant stainless steel makes it suitable for ships, engine rooms, and offshore rigs.

✔ Power Distribution Systems

It is used in heavy-duty crimping at substations, transformers, and high-current wiring.

✔ HVAC & Building Automation

Guarantees reliable connections in high-capacity HVAC motors, switchboards, and automation circuits.

✔ Manufacturing Automation

From conveyors to robotics, secure wiring is critical for uninterrupted operations.

✔ Electrical Maintenance & Field Services

Portable and robust, it’s a tool often used in on-site repair jobs.

Why Choose the Thomas & Betts 15534SS Connector Die?

Choosing the right connector die is critical to ensuring long-term electrical safety and performance. What makes the 15534SS stand out includes:

1. Performance from a Trusted Brand

Thomas & Betts is a globally recognized name in electrical infrastructure for its precision engineering and reliability.

2. Superior Corrosion Resistance

Construction of stainless steel ensures longevity in wet, salty, or chemically harsh environments.

3. Ensures Safe & Strong Connections

A perfectly shaped crimp helps with electrical flow and reduces risks such as overheating, sparking, or terminal loosening.

4. Reduced Maintenance & Operational Downtime

Its durability minimizes the need for replacement, keeping your workforce focused on productivity.

5. Ideal for Professional Installers

If your work requires perfect electrical terminations, this die provides the consistency and control needed.

6. Ideal for Marine & Industrial Use

Designed for high-stress, high-vibration, and high-current operating environments.