| Attribute | Value |

|---|---|

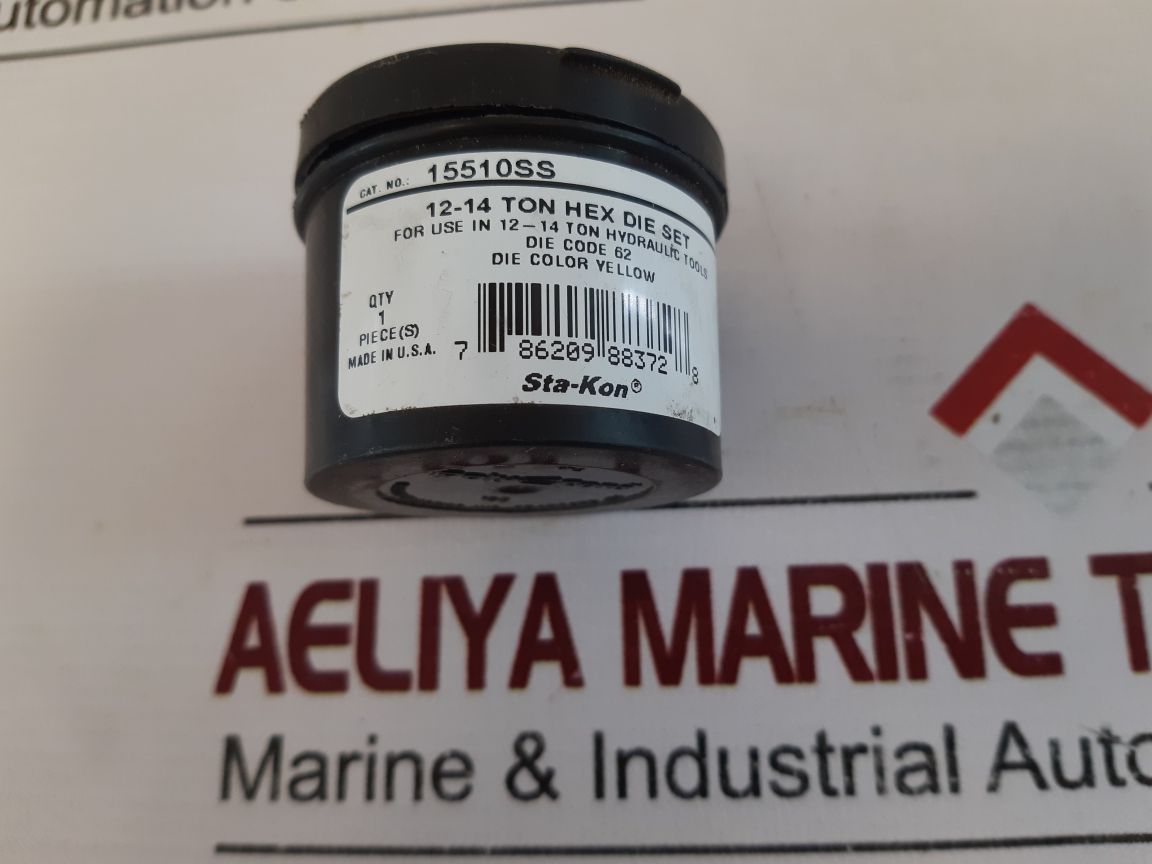

| Product Name | Thomas & Betts 15510SS Connector Die |

| Brand | T&B / Thomas & Betts |

| Series | Sta-Kon |

| Model / Part Number | 15510SS (Die Code 62) |

| Catalog Number | Cat. No. 15510SS |

| Type | 12-14 Ton Hex Die Set |

| Application | For Use in 12-14 Ton Hydraulic Tools |

| Die Color | Yellow |

| Barcode | 7 86209 88372 8 |

| Country of Manufacture | Made in U.S.A. |

| Weight | 250 gm |

| Condition | New (1 Piece) |

| Reference Number | 57670 |

What is the Thomas & Betts 15510SS Connector Die?

The 15510SS is a precision-machined crimping die from Thomas & Betts, a trusted name in electrical connection technology. This die is designed for use with compatible hydraulic crimping tools to create secure, uniform, and high-conductivity crimps on lugs, connectors, and cables.

The 15510SS die is made from high-strength stainless steel, ensuring long life with corrosion resistance, and gives consistent performance even in harsh environments encountered in marine vessels, industrial plants, and outdoor installations.

Its distinctive die size and code make it ideal for particular conductor ranges, ensuring the perfect crimp every time.

Key Features of Thomas & Betts 15510SS Connector Die

1. High-Grade Stainless Steel Construction

Fabricated with extra-strong stainless steel that is resistant to corrosion, wear, and heavy-duty use in marine and industrial environments.

2. Precision-Engineered Crimp Profiles

Provides consistent, reliable crimps that improve electrical conductivity and reduce connection failures.

3. Compatible With Hydraulic Crimping Tools

Designed to fit 12-ton or 14-ton T&B hydraulic tools, depending on the specification, for safe and efficient operation.

4. Accurate Die Code Identification

Each die is clearly marked with a die code for easy verification of connector type compatibility and cable sizes by technicians.

5. Long Service Life

Resistant to mechanical fatigue and environmental damage, thus suitable for continuous professional use.

6. Ensures strong mechanical & electrical bonds.

Thomas & Betts products yield reliable, UL-listed crimps, which consistently outperform the expected performance.

Applications of the 15510SS Connector Die

The Thomas & Betts 15510SS die is widely employed in many different industries that rely on secure electrical terminations:

1. Marine & Offshore Systems

Used for wiring on ships and vessels, engine control panels, navigation systems, and offshore platforms where it is important to have corrosion resistance.

2. Industrial Electrical Installations

Ideal applications include panel builders, switchgear manufacturers, automation systems, and high-load electrical equipment.

3. Power Distribution & Control

Perfect for crimping connectors in substations, MCC panels, power control centers, and energy distribution networks.

4. Automotive & Heavy Machinery

Used for cable terminations in trucks, cranes, excavators, forklifts, and industrial vehicles.

5. Renewable Energy Systems

Useful in solar power plants, wind turbines, and battery energy storage systems where strong cable connections are vital.

6. Maintenance, Repair & Overhaul (MRO)

Reliable tool for technicians performing repairs in field and workshop environments.

Why Choose the Thomas & Betts 15510SS Connector Die?

✔ Trusted Global Brand

Thomas & Betts have been synonymous with providing the best electrical tools and accessories with top-class reliability.

✔ Excellent Durability

It features a stainless-steel body that resists corrosion, scratches, and deformation, making it ideal for long-term applications.

✔ Guaranteed Crimp Quality

It has precision dimensions and die profiles that ensure that each crimp is uniform, safe, and electrically efficient.

✔ Suitable for Various Hostile Environments

The die performs flawlessly-from marine applications to dusty industrial facilities-with no failures.

✔ Fast and Easy Identification

Die markings allow the technicians to quickly select the right die, hence reducing errors and enhancing workflow efficiency.

✔ Improved Safety

Proper crimps reduce overheating, arcing, and mechanical failures—protecting equipment and personnel.