| Attribute | Value |

|---|---|

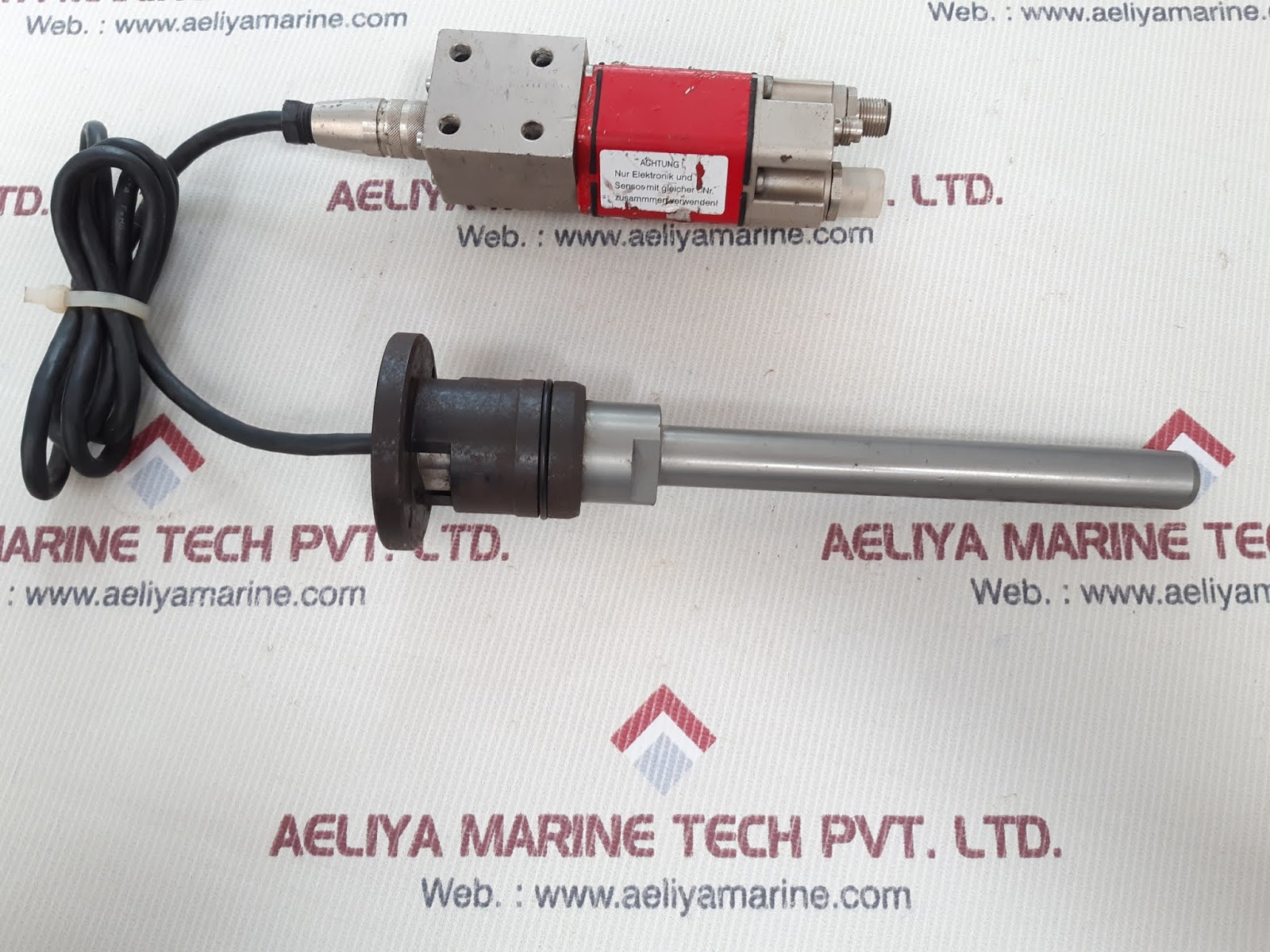

| Model | Temposonics mts z01a124 |

| Manufacturer | Temposonics |

| Series | R-Series |

| Brand | MTS |

| Part Number | RD4BD6S0070MD53P102 |

| Model Number | Z01A124 |

| GRD. | 2791.05 m/s |

| FNR. | 1312 0136 |

| Other Info | =TL+EP1-B1 |

| Weight | 1.160 kg |

Understanding Magnetostrictive Technology:

Before diving into the specifics of the z01a124, it’s crucial to understand the underlying principle of magnetostriction. Magnetostrictive sensors leverage the interaction between magnetic fields and a ferromagnetic material. A pulse of current is sent through a waveguide, generating a magnetic field. This field interacts with a permanent magnet attached to the moving part (e.g., a piston or actuator) being measured. The interaction produces a torsional wave that travels through the waveguide. The time it takes for the wave to return to the sensor head is measured with great accuracy and converted to a highly accurate linear position measurement.

Major Features of the MTS z01a124:

The Temposonics MTS z01a124 is used in demanding applications that need high accuracy, reliability, and longevity. Among some of its major features are:

Non-Contact Measurement: The sensor works without physical contact between the sensor and the moving component, avoiding wear and tear and providing long service life.

High Accuracy and Resolution: The z01a124 provides high accuracy and resolution, allowing accurate position control and feedback.

Robust Construction: Designed to withstand rugged environments, the sensor is shock, vibration, and temperature resistant.

Different Output Options: The z01a124 has different output signals, which provide easy integration into any control system.

Long Stroke Lengths: Long stroke lengths are supported by these sensors, and they are applicable in numerous applications.

Simple Installation: Advanced technology aside, Temposonics sensors are typically easy to install and integrate.

Uses of the MTS z01a124

The flexibility and dependability of the MTS z01a124 make it an ideal candidate for a broad spectrum of applications in many different industries:

Hydraulic and Pneumatic Systems: Accurate position feedback for hydraulic cylinders on industrial equipment, mobile machinery, and aerospace.

Manufacturing and Automation: Position control in robotic arms, CNC equipment, and other automation systems.

Packaging and Material Handling: Sensitive positioning of parts in packaging machines and material handling systems.

Plastics Processing: Tight injection molding machine and extrusion equipment control.

Woodworking: Positional accuracy in woodworking equipment.

Advantages of Selecting the MTS z01a124:

Higher Productivity: Reliability and accuracy of position feedback result in better process control and productivity.

Better Quality: High accuracy measurement ensures product quality consistency and less scrap.

Less Downtime: The heavy-duty construction and non-contact measurement reduce sensor failure downtime.

Reduced Maintenance Costs: Lack of wear and tear decreases the need for maintenance as well as the costs associated with it.

Long Lifespan: Temposonics sensors have a long lifespan and offer a cost-efficient and reliable option.