| Attribute | Value |

|---|---|

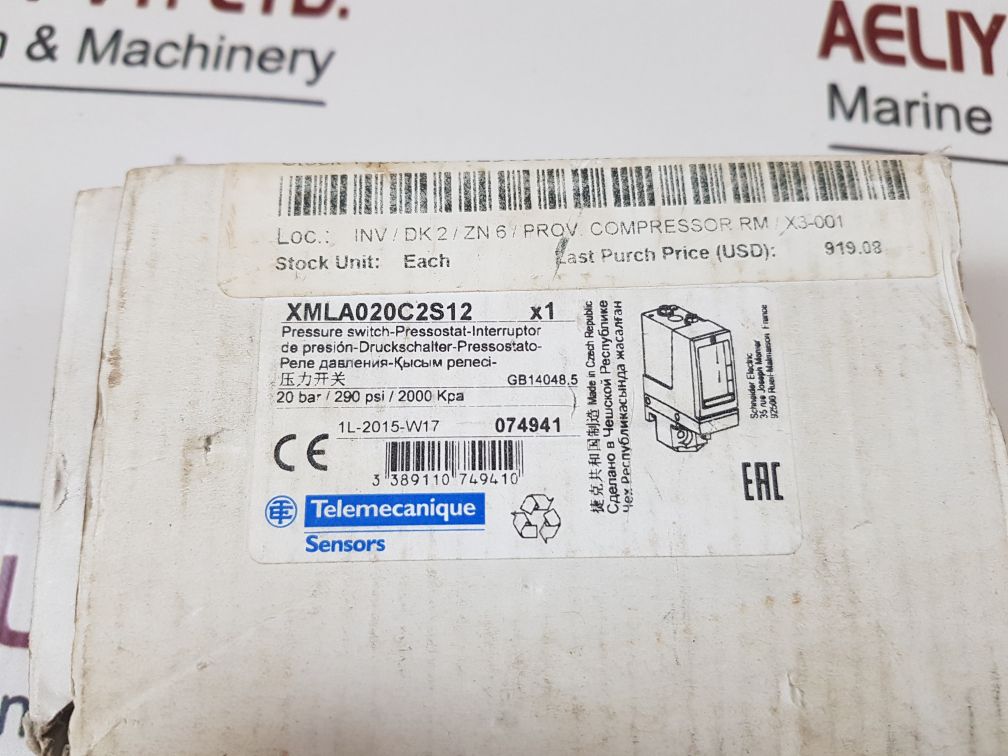

| Brand | Telemecanique / Schneider Electric |

| Model | XMLA020C2S12 |

| Series | XML Nautilus Sensors |

| Range (Pressure) | 100 to 2000 kPa / 14.5 to 290 PSI / 1 to 20 Bar |

| Polarity | Same Polarity |

| Enclosure Type | Type 4X / 12 (IEC/EN 60947-5-1) |

| Rated Insulation Voltage (Ui) | 500V |

| Protection Rating | IP66 |

| Contact Type | AC15 |

| Rated Operational Voltage (Ue) | 240V |

| Rated Operational Current (Ie) | 1.5A |

| Pressure Rating | 20 Bar / 290 PSI / 2000 kPa |

| Standard | GB14048.5 |

| Manufacture Code | 1L1517 / 1L-2015-W17 |

| Barcode | 3 389110 749410 |

| Country of Origin | Czech Republic |

| Weight | 730 gm |

| Condition | New (1 Piece) |

| Reference Number | 44569 |

What is TELEMECANIQUE SCHNEIDER ELECTRIC XMLA020C2S12 Pressure Switch?

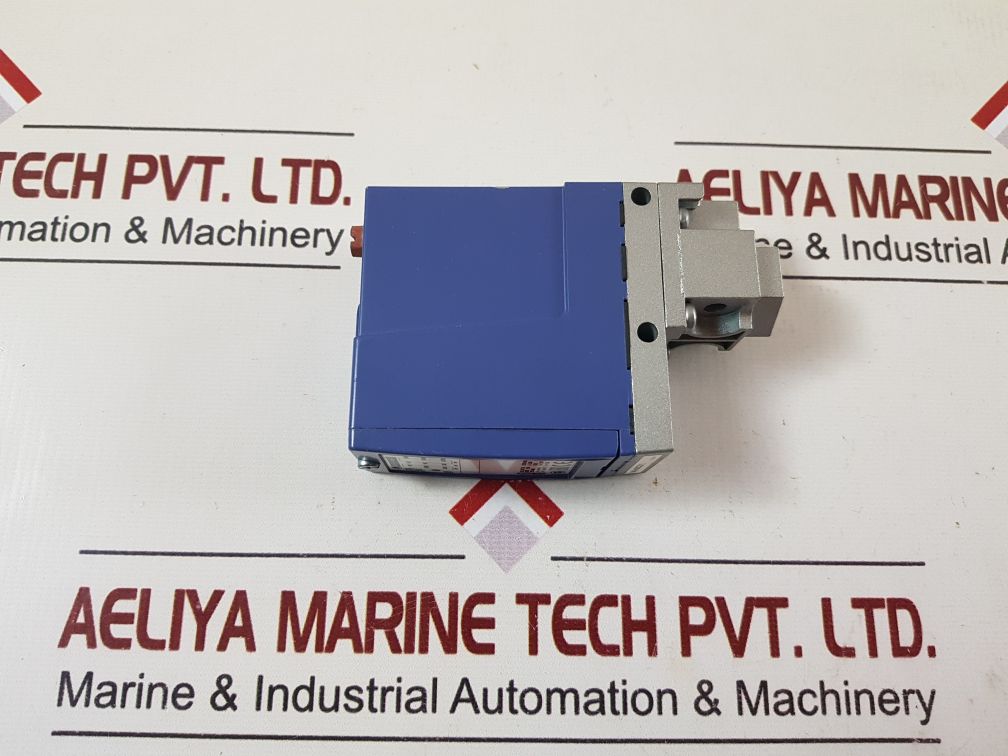

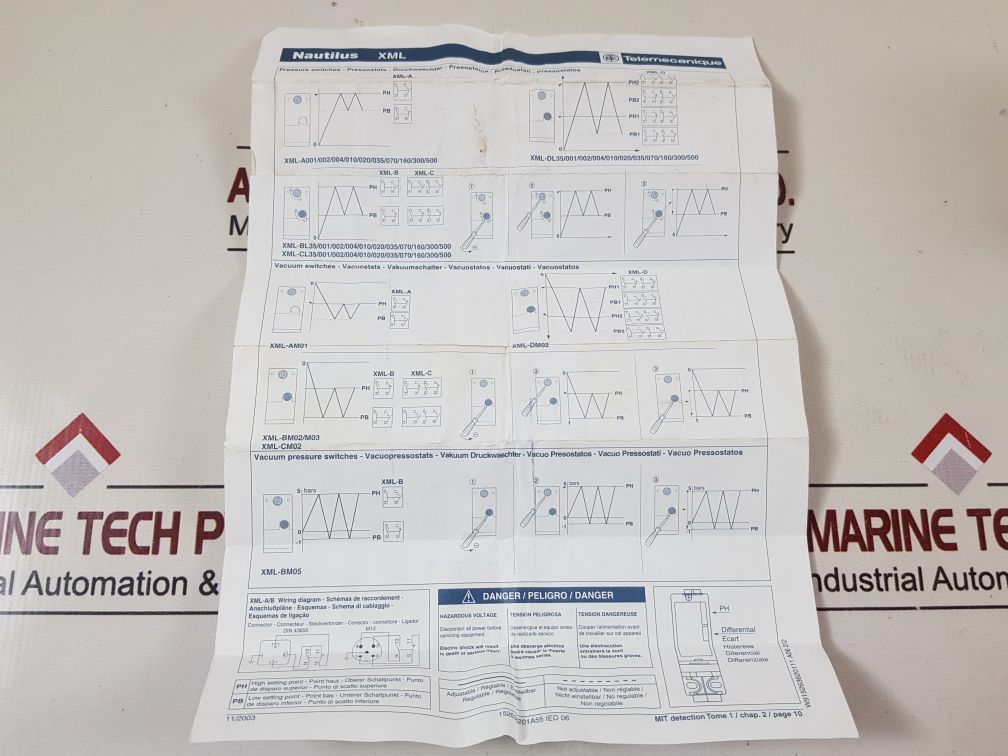

The Telemecanique Schneider Electric XMLA020C2S12 Pressure Switch is a high-performance industrial device designed to monitor and control pressure in automation systems. It operates by detecting changes in system pressure and activating electrical contacts at preset points, ensuring safe and efficient operation across a range of industrial and marine applications.

Manufactured by Schneider Electric, a global leader in automation and energy management, this pressure switch is engineered for precision, reliability, and durability. It is part of the renowned XMLA series, known for robust construction, consistent accuracy, and adaptability to both pneumatic and hydraulic systems.

This model (XMLA020C2S12) features a pressure range of 0–20 bar, making it suitable for a variety of industrial systems that demand accurate pressure monitoring and control under tough environmental conditions.

Key Features

-

Wide Pressure Range – Supports up to 20 bar, ideal for multiple process control applications.

-

High Accuracy & Sensitivity – Offers reliable switching performance for precise control.

-

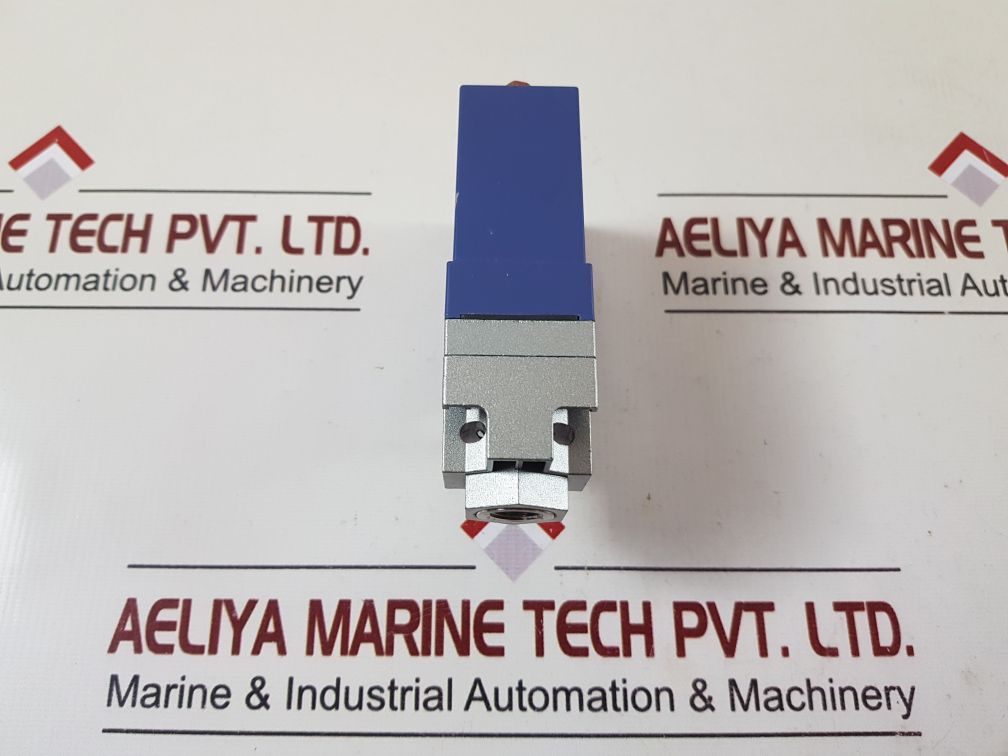

Durable Build – Designed for rugged industrial and marine environments.

-

Compact & Versatile Design – Easy to install in control panels, machinery, or automation systems.

-

Reliable Switching Contacts – Ensures stable performance with minimal maintenance.

-

Brand Trust – Manufactured by Schneider Electric, a trusted name in electrical and automation solutions.

-

Easy Adjustment – Pressure settings can be fine-tuned for specific operational needs.

-

IP-Rated Enclosure – Offers strong resistance to dust, moisture, and mechanical impacts.

Applications

The Telemecanique Schneider Electric XMLA020C2S12 Pressure Switch is widely used in industries that require precise pressure monitoring and safety control:

-

Industrial Automation Systems – For maintaining consistent pressure in production lines.

-

Marine and Offshore Equipment – For monitoring hydraulic and pneumatic systems in ships.

-

Pneumatic and Hydraulic Machines – Ensures correct operating pressure and system protection.

-

Water Treatment Plants – Controls pumps and compressors based on set pressure levels.

-

HVAC Systems – Monitors and regulates pressure in heating and cooling circuits.

-

Oil & Gas Industry – Used in control systems to maintain optimal process conditions.

-

Power Generation Units – Ensures safety in turbines and auxiliary systems.

Whether it’s automation, marine engineering, or energy systems, this pressure switch delivers consistent results and minimizes downtime.

Why Choose TELEMECANIQUE SCHNEIDER ELECTRIC XMLA020C2S12 Pressure Switch?

Choosing this Schneider Electric pressure switch means investing in quality, safety, and reliability. Here’s why it’s a smart choice for engineers and technicians:

-

Proven Reliability: Schneider Electric is a global leader with decades of experience in industrial automation.

-

Long Service Life: Built to endure high-pressure operations and harsh environments.

-

Maintenance-Free Operation: Offers reliable switching without frequent recalibration.

-

Compact & Cost-Effective: Provides advanced control in a small, budget-friendly design.

-

Easy Integration: Compatible with a variety of industrial and marine control systems.

-

Energy Efficient: Helps optimize system performance and reduce operational costs.

By integrating this pressure switch, operators can improve system efficiency, reduce failures, and enhance operational safety.