| Attribute | Value |

|---|---|

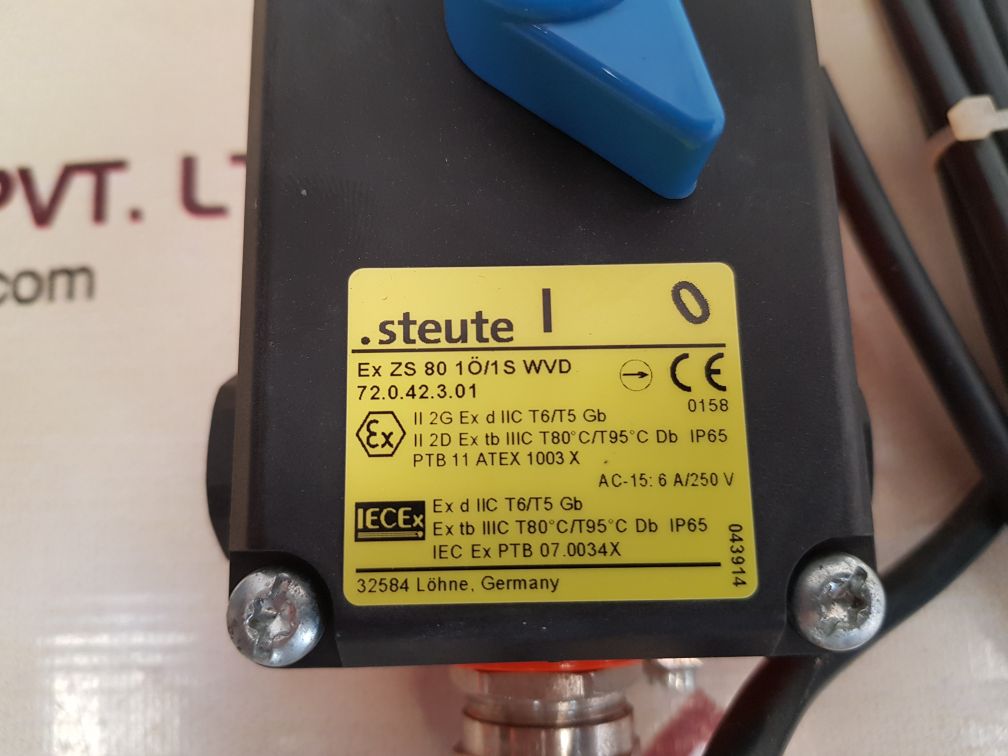

| Product Name | Steute EX ZS 80 1O/1S WVD Emergency Pull-Wire Switch with Safety Function |

| Model | EX ZS 80 1O/1S WVD |

| Part Number | 72.0.42.3.01 |

| Additional Code | 0158 |

| ATEX Certification | II 2G Ex d IIC T6/T5 Gb II 2D Ex tb IIIC T80°C/T95°C Db IP65 PTB 11 ATEX 1003X |

| Electrical Rating | AC-15: 6A / 250V |

| IECEx Certification | Ex d IIC T6/T5 Gb Ex tb IIIC T80°C/T95°C Db IP65 IECEx PTB 07.0034X |

| Reference Number | 043914 |

| Country of Origin | Germany |

| Weight | 970 gm |

What is the Steute EX ZS 80 1O/1S WVD Emergency Pull-Wire Switch?

The Steute EX ZS 80 1O/1S WVD is an industrial emergency pull-wire switch designed for hazardous and explosive environments (EX zones). It allows operators to trigger an emergency stop by pulling a wire installed along industrial conveyors, processing lines, and machinery areas.

Unlike standard emergency stop buttons, a pull-wire switch covers long distances—often several meters—making it accessible from anywhere along the installation path. This ensures immediate shutdown of equipment in case of danger, preventing accidents, equipment damage, or production downtime.

The model features 1 normally open (1O) and 1 normally closed (1S) contact configuration, offering reliable switching performance for safety circuits.

Key Features of the Steute EX ZS 80 1O/1S WVD

1. Explosion-Proof Construction

Designed for Zone 1 and Zone 21 hazardous areas, this switch ensures safe operation in environments with gas, dust, or combustible materials. Its rugged housing protects internal components from sparks, heat, and impacts.

2. Long Monitoring Distance

The pull-wire system enables emergency stopping across conveyor belts or extended machinery sections, offering superior accessibility compared to localized emergency buttons.

3. High Mechanical Durability

Built to withstand tough industrial conditions, the switch features corrosion-resistant materials suitable for heavy industries like mining, marine environments, oil & gas facilities, and manufacturing units.

4. Reliable Contact System (1O/1S)

Equipped with:

-

1 Normally Open (NO) contact

-

1 Normally Closed (NC) contact

This ensures dependable signaling for emergency stop and safety monitoring circuits.

5. Easy Installation and Maintenance

The switch includes adjustable tension indicators, accessible terminals, and robust mounting options that simplify installation and reduce downtime during maintenance.

6. Visible Wire Tension Indicator

A clear display shows the correct wire tension, ensuring the system remains ready to operate. If tension drops, the switch trips automatically for safety assurance.

7. IP66 / IP67 Protection

Highly resistant to dust, water, moisture, and industrial contaminants—ideal for outdoor or harsh indoor environments.

Applications of Steute EX ZS 80 1O/1S WVD

This safety switch is widely used in industries where emergency stopping across long distances is required, especially in hazardous areas. Typical applications include:

Conveyor Systems

Used in bulk handling industries such as mining, cement plants, steel mills, and packaging facilities where long conveyors operate continuously.

Chemical and Petrochemical Plants

Ideal for hazardous zones with flammable gases, vapors, or dust.

Oil & Gas Refineries

Ensures instant emergency shutdown around pipelines, compressors, and processing units.

Marine and Offshore Platforms

Its corrosion-resistant design makes it suitable for ships, drilling rigs, and marine automation systems.

Food Processing & Pharmaceutical Plants

Supports hygienic, sealed protection where chemical washdowns or powdered materials are present.

Heavy Manufacturing Systems

Used for assembly lines, machinery guarding, or automated production units requiring robust safety mechanisms.

Why Choose the Steute EX ZS 80 1O/1S WVD?

1. Trusted Global Safety Brand

Steute is known worldwide for producing high-integrity safety switches with certifications for explosive environments and industrial automation.

2. Superior Emergency Response

A pull-wire switch allows immediate reaction from any point along the machinery, improving safety and reducing accident risks.

3. Built for Harsh Environments

Whether exposed to chemicals, high temperatures, moisture, or dust, the EX ZS 80 performs reliably without failure.

4. Certified for Hazardous Areas

Compliance with ATEX, IECEx, and other global safety standards ensures suitability for sensitive and regulated industries.

5. Minimal Downtime

Its durable design and easy maintenance help prevent operational interruptions, saving time and costs for industrial operators.

6. Flexible Integration

Compatible with a wide range of industrial safety circuits, PLC systems, and emergency shutdown controls.