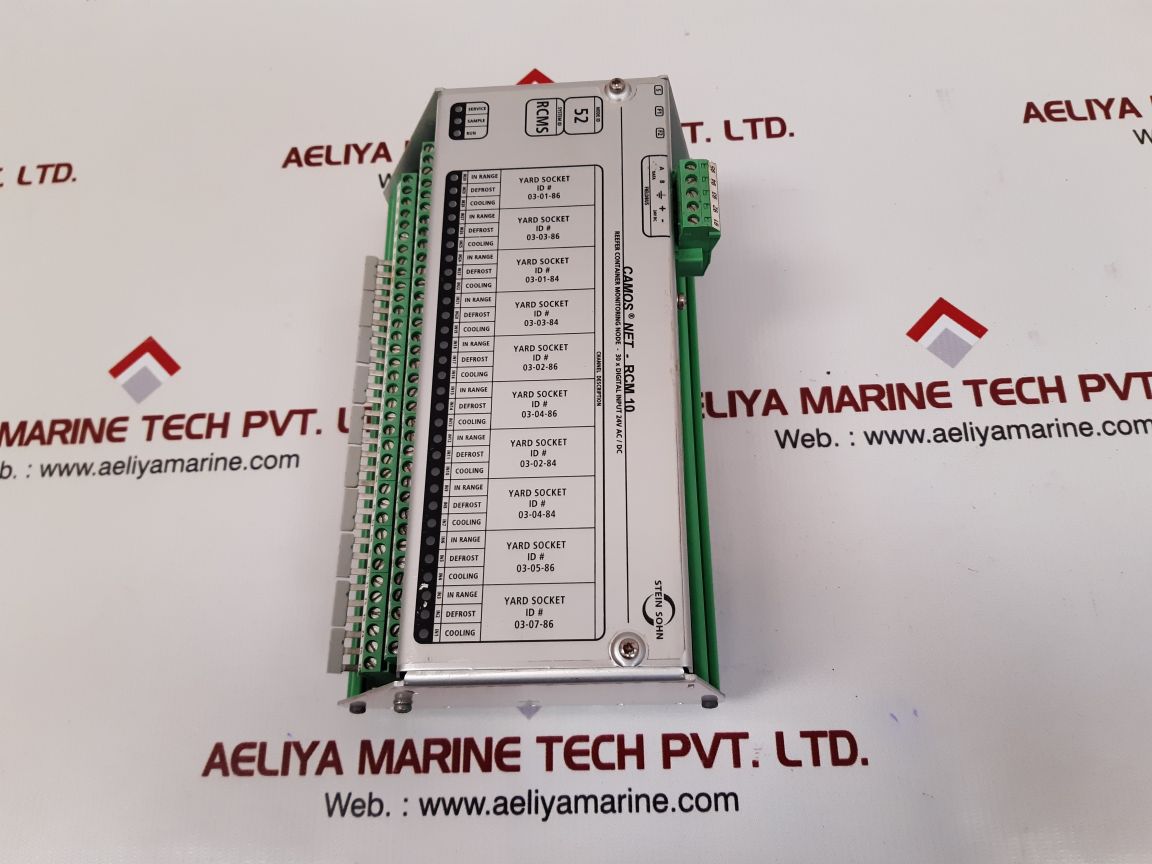

| Attribute | Value |

|---|---|

| Brand | Stein Sohn |

| Product Name | CAMOS Net – RCM 10 |

| Application | Reefer Container Monitoring |

| Part Number | B101002A 000000152 |

| Manufacturer | H.M. Stein Sohn GmbH |

| Connector Brand | Phoenix Contact |

| Node Type | Node-30 x Digital Input 24V AC/DC |

| Node ID | 52 |

| System ID | RCMS |

| Typ | UM 108-FE |

| Country of Origin | Germany |

| Weight | 660 gm |

What is Stein Sohn Camos Net RCM 10?

The RCM 10, or Reefer Container Monitoring, is part of Stein Sohn’s CAMOS NET solution, which was specifically created for reefer container monitoring and management on cargo ships. These solutions are designed to provide better visibility, automation, and control, enabling operators to remotely and real-time monitor conditions.

B101002A version is one among the particular module arrangements employed within various contemporary cargo vessels for the acquisition and processing of accurate reefer container information.

Key Features

Live Data Acquision

The RCM 10 repeatedly gathers data from integrated reefer containers with regards to their temperature, humidity, and function.

Remote Access and Monitoring Potential

Crew may track container condition from a control room, rather than physically checking every container. This conserves time and limits error.

Alarm & Fault Reporting

Automated alarms occur if a reefer container strays from pre-set parameters. Early alarming avoids cargo deterioration and equipment damage.

Modular Design

The RCM 10 system, particularly the B101002A model, is modular and expandable. It is simpler to upgrade or maintain.

Data Logging and Reporting

The system logs critical performance data over time. This information is essential for audits, problem-solving, and optimizing shipping procedures.

Applications

The CAMOS NET RCM 10 is applied extensively on reefer cargo involving container vessels. Common applications include:

- Ocean Freight Organizations

- Refrigerator Cargo Ships

- Port Terminal Administration

- Third-Party Reefer Monitoring Services

Its toughness, seagoing capability, and networking capability with onboard systems make it best suited for high-stress conditions.

Benefits for Ship Operators and Cargo Owners

Less Labor Cost: Hands-off monitoring saves labor costs.

Protection for the Cargo: On-time alert ensures valuable cargo safety.

Workload Efficiency: Simplified integration with shipboard systems enhances the process.

Security in Mind: Ensure your cargo’s safety even halfway across the sea.