| Attribute | Value |

|---|---|

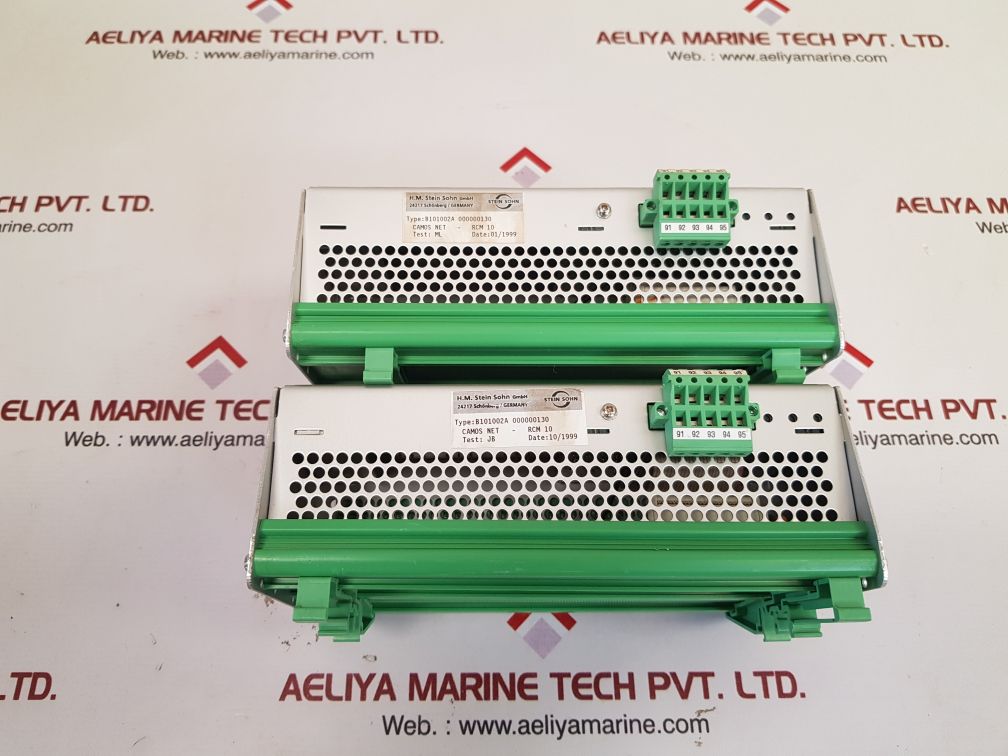

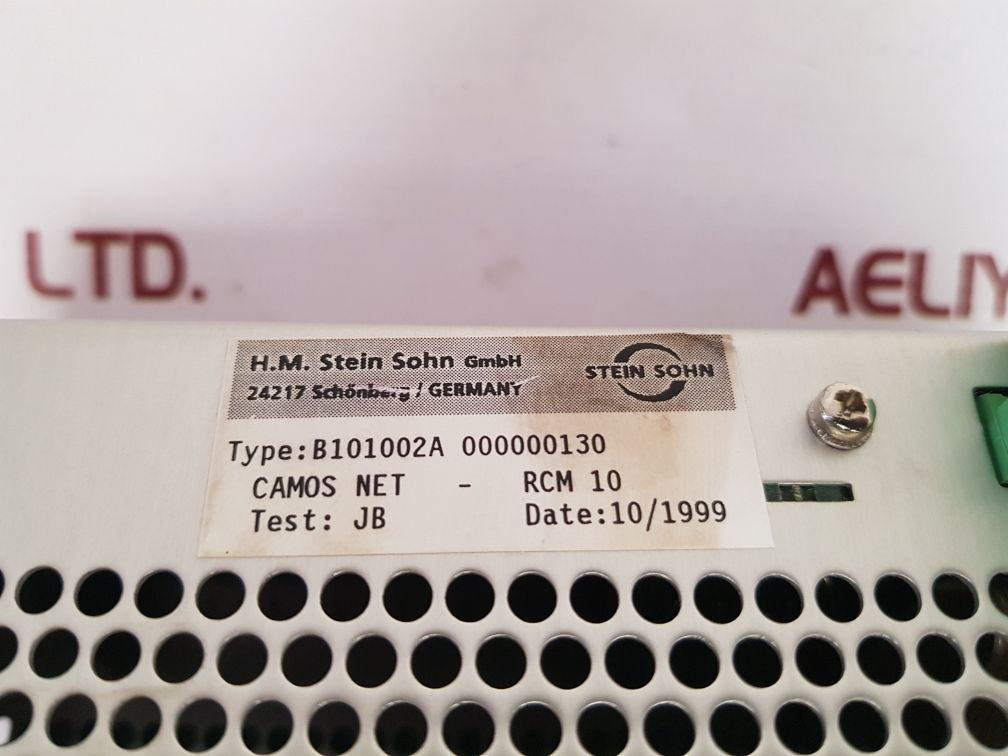

| Manufacturer | H.M. Stein Sohn GmbH |

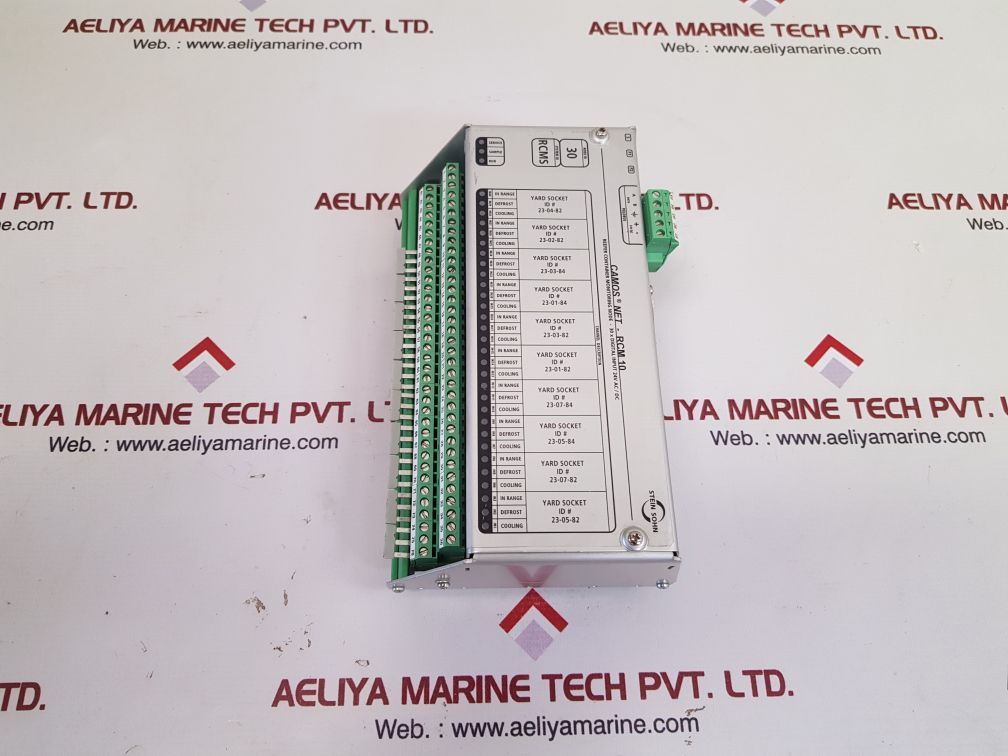

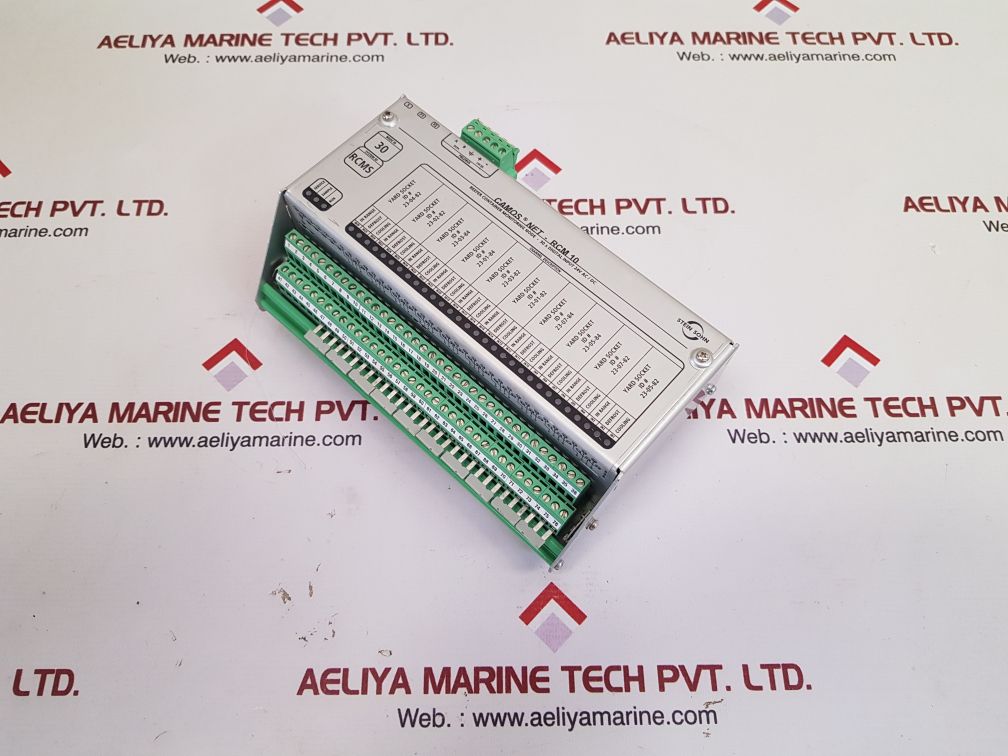

| Model | CAMOS NET-RCM 10 |

| Application | Reefer Container Monitoring |

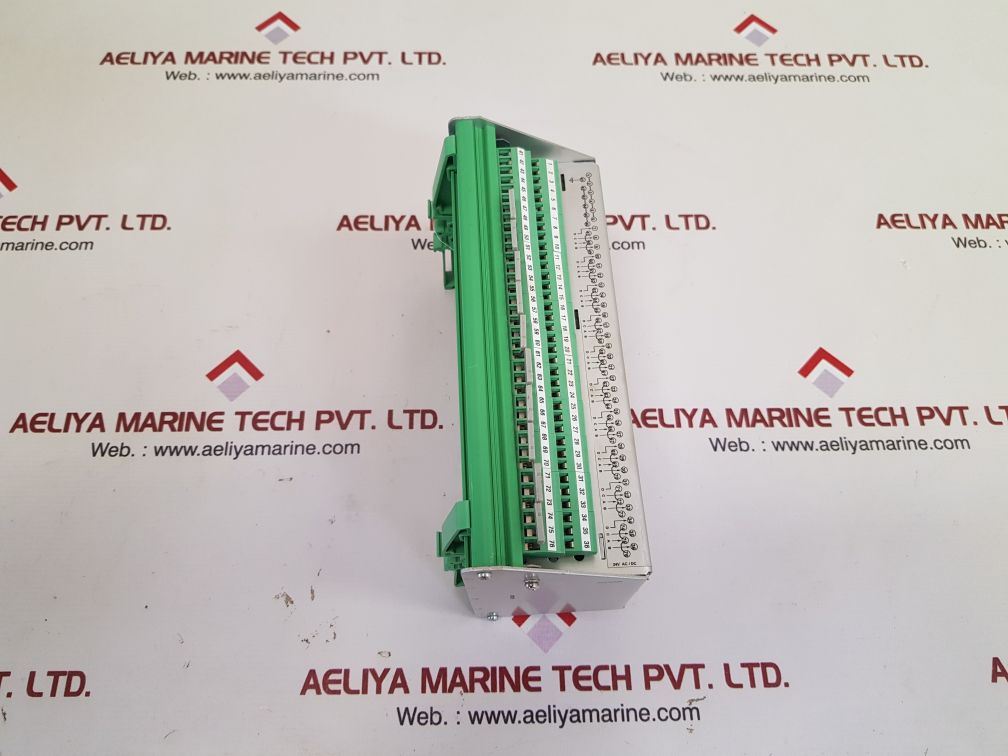

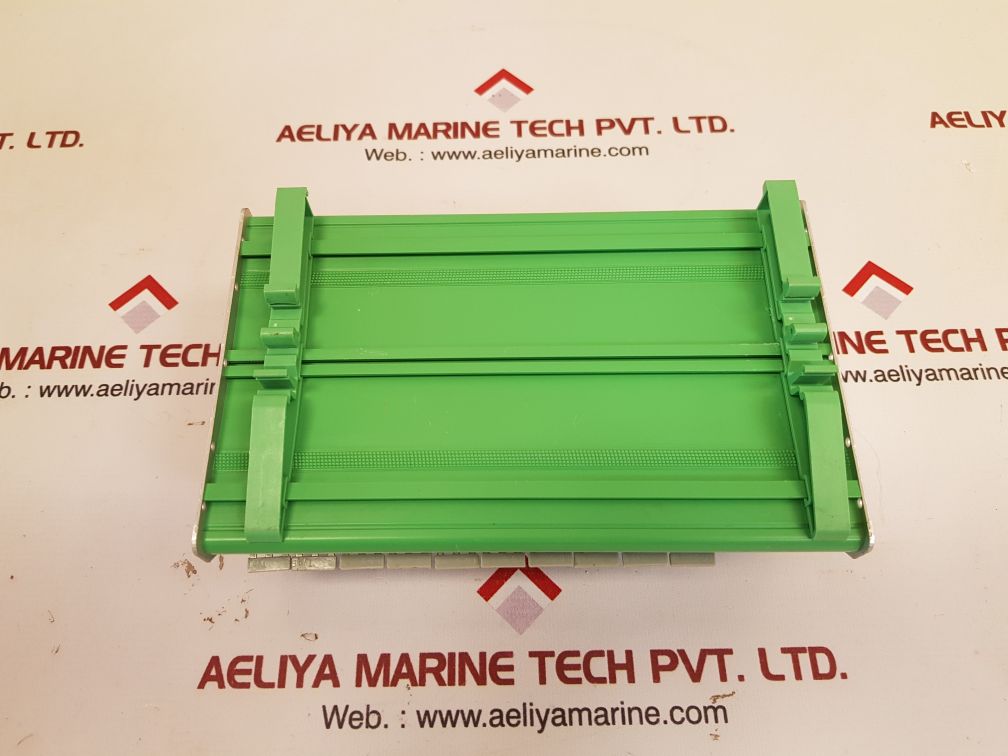

| Description | Node-30 x Digital Input 24V AC/DC |

| Node ID | 37 |

| System ID | RCMS |

| Type | B101002A 000000137 |

| Country | Germany |

| Weight | 670 gm |

What is Stein Sohn CAMOS NET-RCM 10?

The CAMOS NET-RCM 10, having reference code B101002A / 000000137, is a dedicated reefer container monitoring device produced by Stein Sohn. This equipment is specifically created to offer real-time data acquisition, remote monitoring, and control of refrigerated containers, so that your goods remain at the set temperature during its transit.

Main Features

Real-Time Monitoring

The CAMOS NET-RCM 10 constantly monitors internal container temperatures, humidity, and system status. With real-time information, you can identify any problems before they escalate into major issues.

Remote Access and Control

With its network features, the NET-RCM 10 enables operators to remotely access container information. You can review readings, set conditions, or trigger diagnostics—all without having to physically intervene.

Data Logging and Reporting

With built-in memory and connectivity, this device logs essential data for auditing, compliance, and reporting. You’ll have detailed records of your reefer’s performance over time.

Durability and Marine-Grade Build

Designed for use in harsh environments, including onboard ships, it features a rugged casing and reliable electronics that resist corrosion, moisture, and vibration.

Compatibility and Integration

It works smoothly with contemporary reefer container systems and monitoring solutions. This provides compatibility between different brands and models of containers.

Uses of the NET-RCM 10

Shipping Lines

Track refrigerated shipments while at sea to keep perishable commodities such as seafood, pharmaceuticals, and produce under optimal conditions.

Port and Terminal Operations

Guarantee reefer containers are under proper conditions when being loaded, unloaded, and stored at terminals.

Cold Chain Logistics Providers

Enhance supply chain visibility and ensure industry compliance and regulation standards.

Food and Beverage Sector

Monitor cargo integrity from farm through to fork for enhanced food safety along the distribution channel.

Benefits

Increased Operational Efficiency: Reduced manual inspection and faster system alert response.

Less Cargo Loss: Detect faults before they result in spoilage.

Enhanced Compliance: Comply with regulation requirements for transportation of perishables.

Peace of Mind: Be assured that your cargo is being tracked 24/7, even halfway around the globe.