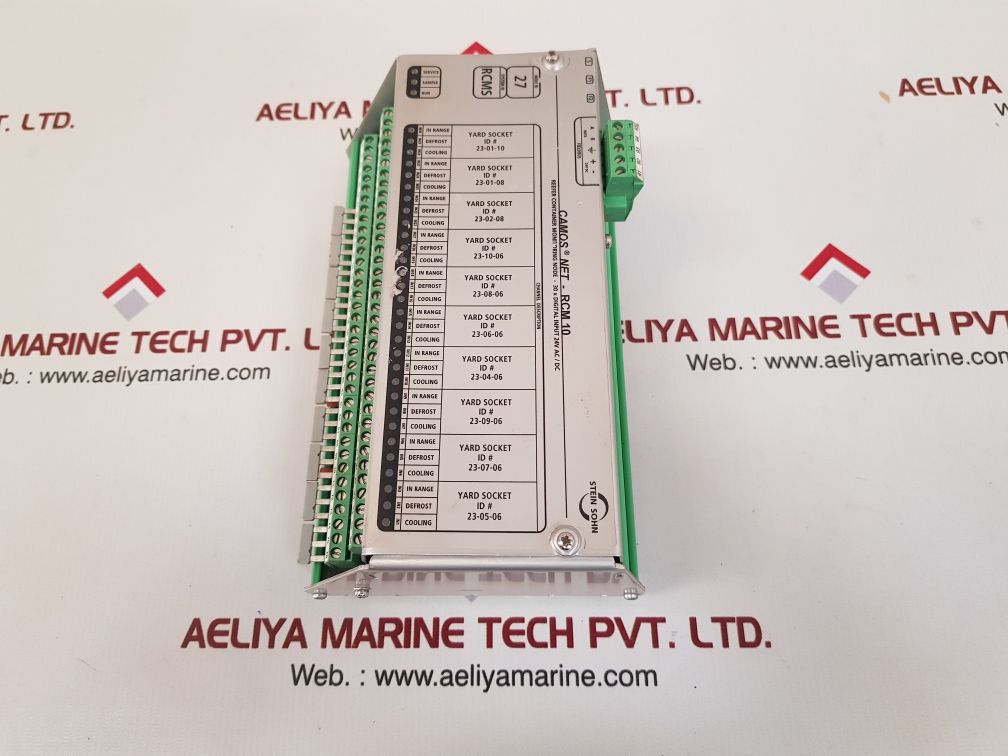

| Attribute | Value |

|---|---|

| Manufacturer | H.M. Stein Sohn GmbH |

| Brand | Phoenix Contact |

| Type | B101002A 000000127 |

| Model | Camos Net- RCM 10 |

| Application | Reefer Container Monitoring Node – 30 x Digital Input 24V AC/DC |

| Node ID | 27 |

| System ID | RCMS |

| Type | UM 108 FE |

| Country | Germany |

| Weight | 680 gm |

Features of RCM 10 Reefer Monitoring

1. Real-Time Temperature Monitoring

RCM 10 monitors temperature variations within the container on a real-time basis. It records such temperature variations throughout. This assists in avoiding spoilage and ensuring temperature-sensitive shipments stay within acceptable temperatures.

2. Advanced Data Logging & Alerts

The system records temperature, humidity, door position, and power supply status and sends real-time notifications in case of any drift. This provides operators with enough time to respond before cargo quality is affected.

3. Effortless IoT & Cloud Integration

RCM 10 offers seamless integration with contemporary Internet of Things (IoT) and cloud-based infrastructures. Shipping lines, freight forwarders, and cold chain operators can then access real-time information remotely.

4. Smart Diagnostics & Energy Efficiency

Stein Sohn Camos Net has developed the RCM 10 with energy-saving technology that minimizes power consumption without compromising performance. The system also offers smart diagnostics to assist operators in identifying possible mechanical failure before actual failure occurs.

5. Cold Chain Regulations Compliance

The system complies with international standards like HACCP (Hazard Analysis and Critical Control Points), GDP (Good Distribution Practices), and ISO 9001, maintaining compliance with food safety and pharmaceutical regulations.

How RCM 10 Enhances Reefer Container Operations

1. Reduces Cargo Loss & Spoilage

Due to real-time temperature monitoring and alerts, RCM 10 greatly reduces the risk of product spoilage, bringing perishable commodities in perfect condition.

2. Increases Operational Efficiency

Through automated temperature recording and condition reports of containers, RCM 10 avoids manual checks, conserving time, and decreasing human errors in reefer tracking.

3. Increases Supply Chain Transparency

RCM 10 delivers real-time transparency to stakeholders so that shipping operators, logistics partners, and end-customers may monitor shipments step by step.

4. Reduces Maintenance Cost

Predictive diagnostics enable the operators to discover and repair mechanical faults prior to system failure, minimizing downtime as well as costly maintenance.

Who Can Gain Benefit from RCM 10 Reefer Monitoring?

The RCM 10 platform is best suited for industries involving rigorous temperature regulation, such as:

Food & Beverage Industry – Preparing fresh produce, dairy, meat, and frozen foods to stay in top condition.

Pharmaceuticals & Healthcare – Controlling stringent temperature controls for vaccines, drugs, and biological samples.

Logistics & Shipping Companies – Optimizing reefer containers in international trade.

Retail & E-Commerce – Guarding food safety in internet-based grocery shopping and meal delivery.