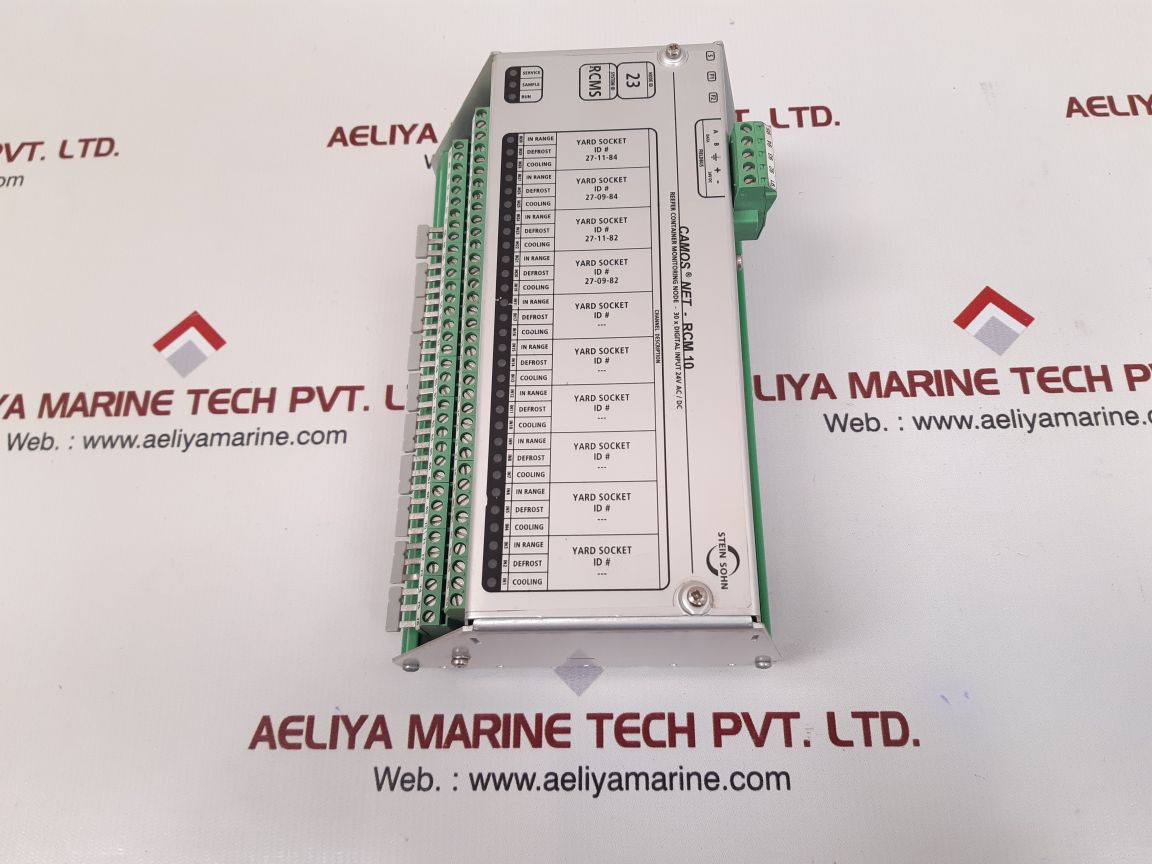

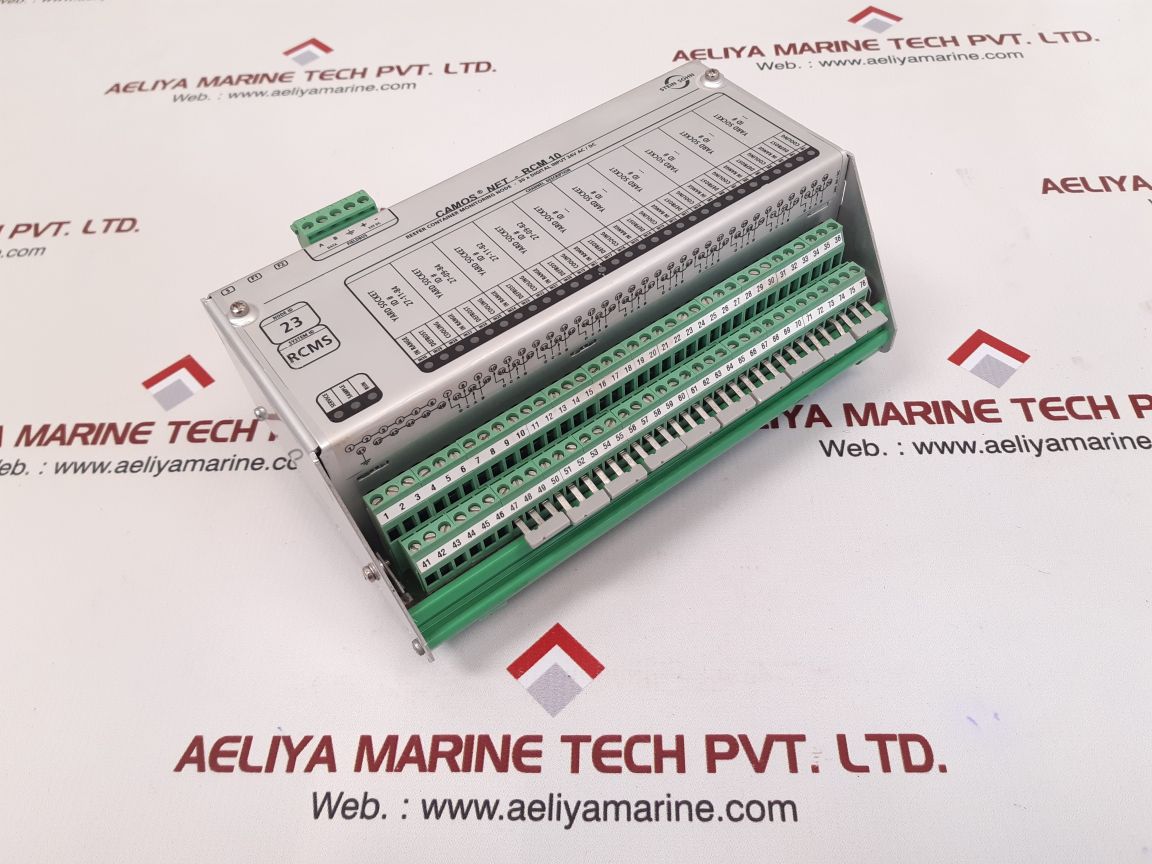

| Attribute | Value |

|---|---|

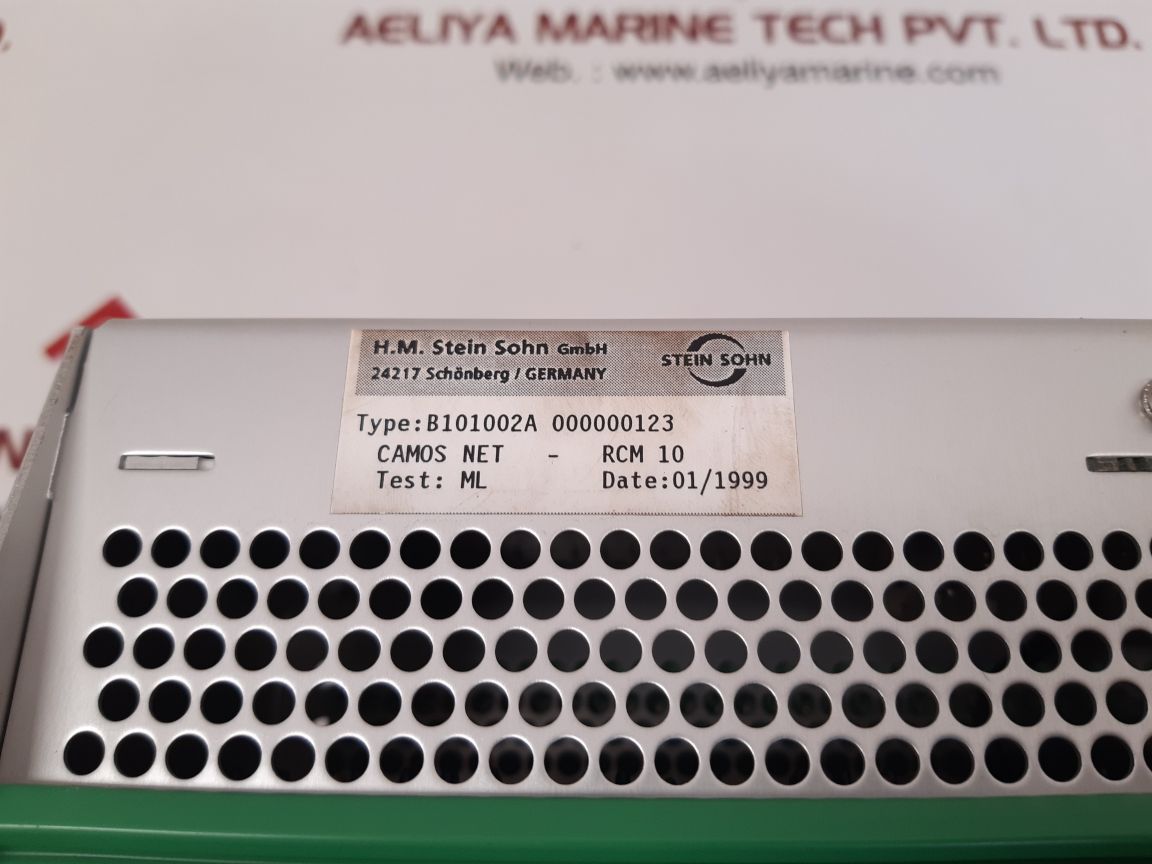

| Manufacturer | H.M. Stein Sohn GmbH |

| Partners | Phoenix Contact |

| Model | Camos Net-RCM 10 |

| Function | Reefer Container Monitoring |

| Input Type | 30 x Digital Input 24V AC/DC |

| Node ID | 46 |

| System ID | RCMS |

| Type | B101002A 000000146 |

| Typ | UM 108 FE |

| Country | Germany |

| Weight | 670 gm |

What Is the Stein Sohn CAMOS NET-RCM 10?

The CAMOS NET-RCM 10 is a reefer container monitoring module created by Stein Sohn, a well-established marine electronics and control systems company. The device is a part of their high-end reefer control line, precisely designed to monitor temperature, humidity, and other important conditions within reefer containers in real-time.

Whether transporting perishable food, pharmaceuticals, or chemicals, this system helps operators maintain the integrity of sensitive cargo across long voyages.

Key Features and Specifications

Here’s what makes the CAMOS NET-RCM 10 a powerful choice for reefer monitoring:

1. Real-Time Monitoring

This unit enables live data transmission from the reefer container to the control center, providing instant updates on internal conditions like temperature and humidity.

2. Advanced Alarm System

Integrated alarm functionality notifies operators of abnormal status. Whether temperature spike or equipment failure, the system provides prompt intervention.

3. Network Compatibility

As implied by the “NET” in its name, the NET-RCM 10 is easily integrated into onboard networks, with seamless data communication between reefer containers and monitoring stations.

4. User-Friendly Interface

The system is equipped with a bright, easy-to-read display—ideal for rapid status review and on-the-fly changes. Some configurations have remote access capabilities for off-site inspection.

5. Rugged Marine Construction

Designed to withstand the tough conditions found in marine applications, the NET-RCM 10 is encased in ruggedized housing to shield it from water, corrosion, and mechanical stress.

Uses of the CAMOS NET-RCM 10

This reefer monitoring system has broad application throughout the shipping sector at sea. Major applications are:

Cargo Ships & Container Vessels: Constant monitoring of reefer containers to keep cargo within controlled temperature ranges.

Offshore Platforms: For food or chemical storage where environmental conditions can affect product quality.

Cold Chain Logistics Providers: Incorporated into reefer containers for overland transport when combined with satellite tracking systems.

Port Storage Facilities: Allows centralized temperature data collection for containers in transit or waiting to depart.

Benefits of Using This System

The CAMOS NET-RCM 10 provides various benefits that enhance operating efficiency and cargo protection:

Less Spoilage & Waste: Constant reefer conditions ensure minimized losses through reduced temperature variation.

Better Compliance: Facilitates compliance with industry and government regulations for temperature-controlled products.

Lower Maintenance Costs: Early alerts and diagnostics minimize equipment downtime and avoid costly repairs.

Data Logging for Audits: Comprehensive records facilitate traceability and conflict resolution in the event of cargo damage.