| Attribute | Value |

|---|---|

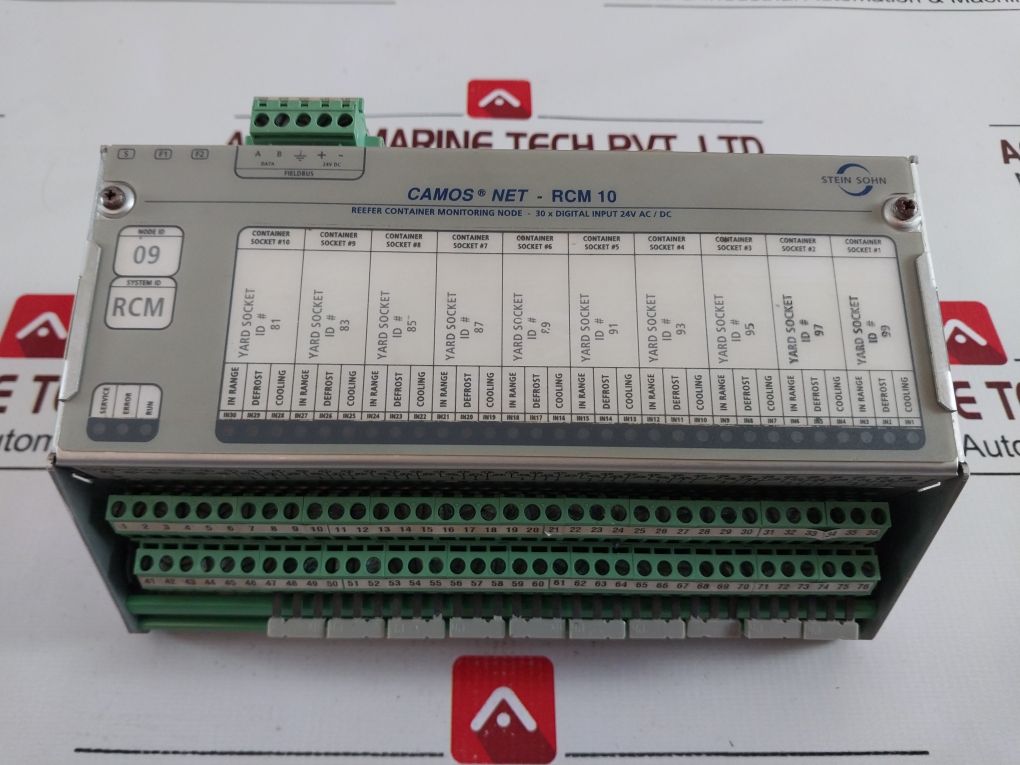

| Manufacturer | Stein Sohn |

| Model | B101002a 000000109 |

| Product Name | Reefer Container Monitoring Node |

| System | Camos Net-rcm 10 |

| Specifications | 30x Digital Input 24V AC/DC |

| Node ID | 09 |

| System ID | RCM |

| Weight | 670 gm |

| Condition | Used (1 Pcs) |

| Reference No | 61269 |

What Is a Reefer Container Monitoring Node?

A reefer container monitoring node is an exclusive device designed for continuous tracking and reporting on the inside conditions of a refrigerated container. Reefer devices ensure that cargo remains within the required temperature and humidity levels as it transports the cargo and supplies real-time data to shippers, logistics companies, and customers.

The Stein Sohn B101002a 000000109 is one such monitoring node that has been crafted with precision engineering and advanced technology to provide flawless and reliable monitoring solutions for reefer containers.

Key Features of the Stein Sohn B101002a

Real-Time Temperature Monitoring

This feature allows instant temperature readings to ensure cargo is stored at the optimal temperature.

Humidity Control

Monitors and controls humidity levels to maintain the freshness of perishable goods.

Remote Data Transmission

Sends real-time alerts and reports to stakeholders, allowing for prompt corrective action when necessary.

Energy Efficient

Optimized to operate on low power, reducing energy consumption without compromising performance.

Rugged and Durable Design

Built to last in the toughest marine and shipping environments, with long-term reliability.

User-Friendly Interface

Easy installation and operation with an intuitive dashboard for monitoring.

Why Is Reefer Container Monitoring Important?

In the global supply chain, efficiency and reliability are not negotiable. Reefer container monitoring nodes such as the Stein Sohn B101002a 000000109 play an important role in ensuring the integrity of goods that are transported all over the world.

Here’s why they matter:

Prevents Spoilage and Waste: Monitoring ensures perishable goods remain fresh and within regulatory limits.

Regulatory Compliance: Several industries have very strict guidelines on temperature-controlled transportation; monitoring nodes help meet these requirements.

Real-Time Alerts and Reports: The immediate notification of any temperature fluctuation helps avoid costly losses.

Increases Operational Efficiency: Automated monitoring reduces manual checks, freeing up time and resources for logistics providers.