| Attribute | Value |

|---|---|

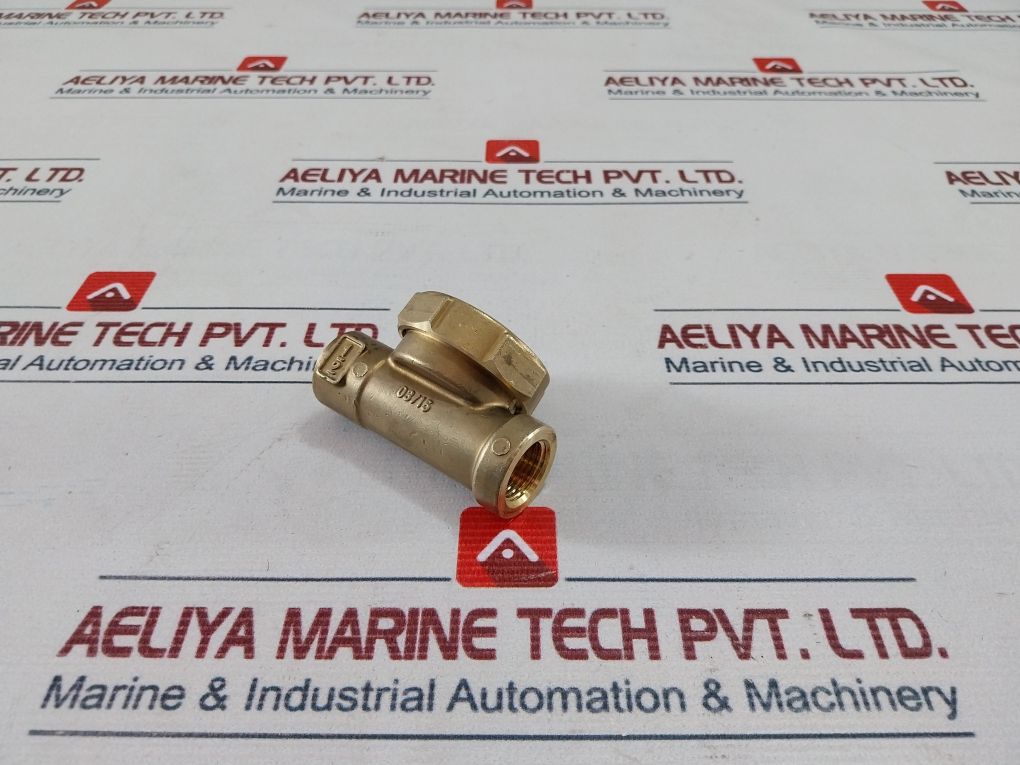

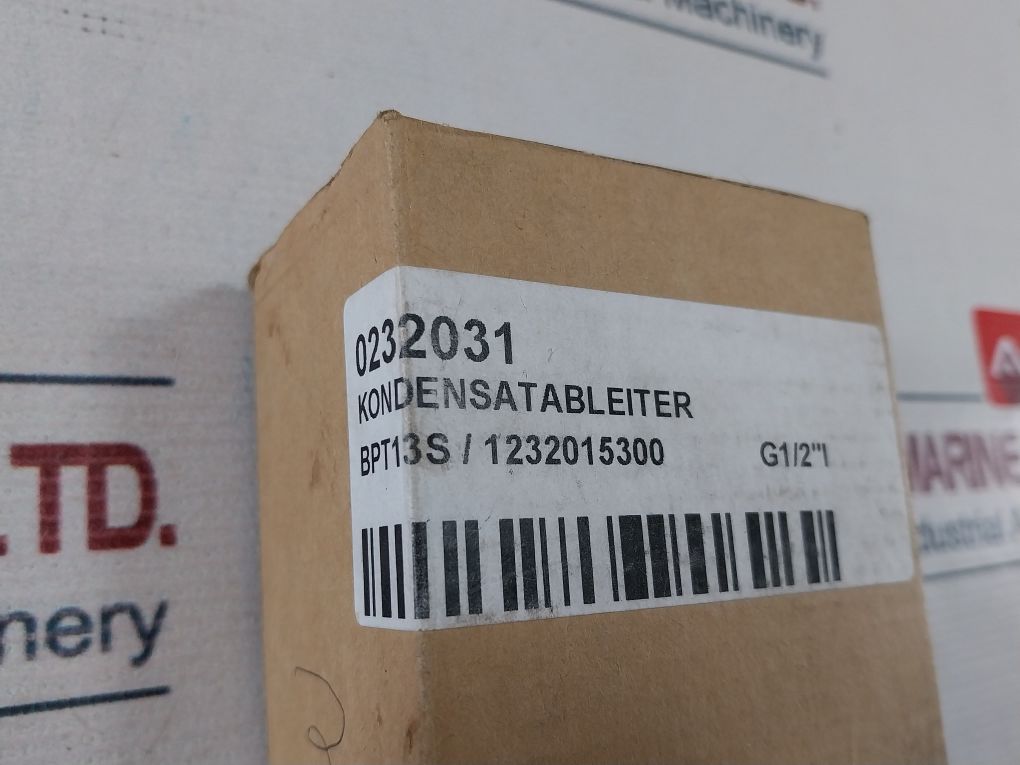

| Product Name | Spirax Sarco BPT13S Thermostatic Steam Trap |

| Made By | Spirax Sarco |

| Type | Kondensatableiter / Condensate Train |

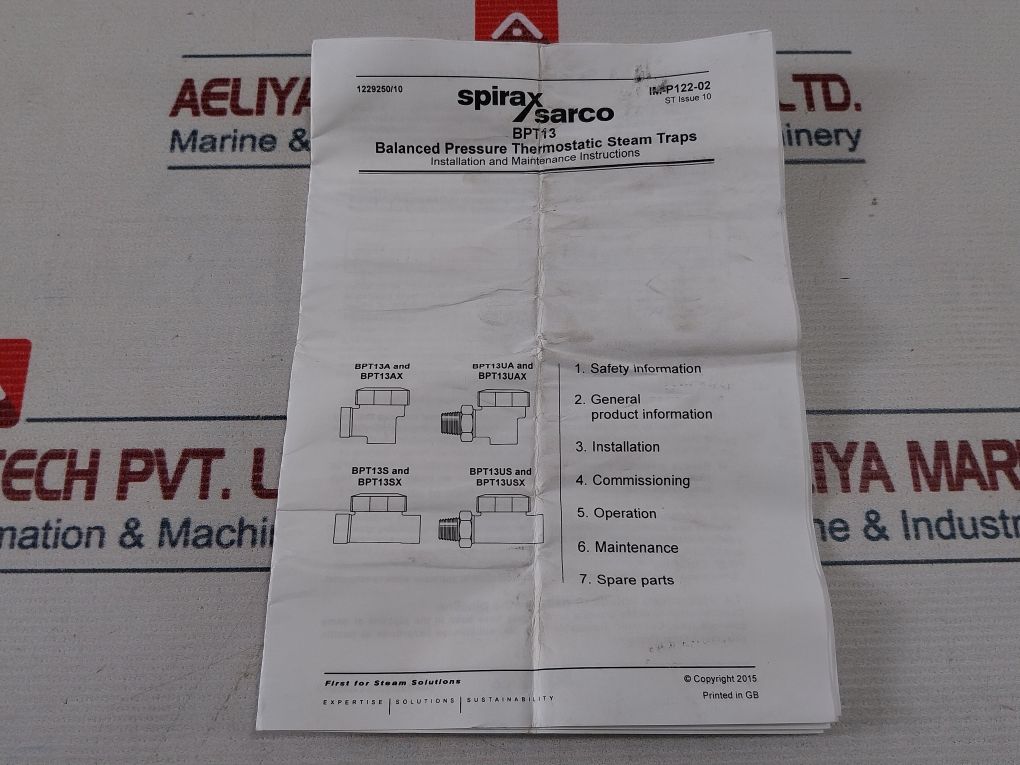

| Technology | Balanced Pressure Thermostatic Steam Traps |

| Model | BPT13 / BPT13S |

| Connection | M15 / M3 |

| Max Allowable Pressure (PMA) | 16 Bar+ |

| Max Allowable Temperature (TMA) | NTS 250°C |

| Max Operating Pressure (PMO) | 13 Bar |

| Material Standard | MS PN16 |

| Part Number | 1225700 |

| Additional Code | M15/DR |

| Product Code | 0232031 |

| Full Model Number | BPT13S/1232015300 |

| Connection Size | G1/2″ I |

| Country of Origin | Made in GB |

| Weight | 510 gm |

| Reference Number(s) | 80332 |

What is Spirax Sarco BPT13S Steam Trap?

The Spirax Sarco BPT13S is a thermostatically operated steam trap based on balanced pressure. Designed for application within different industrial processes, it’s perfect for clean steam, trace lines, and sterile steam processes where reliability and hygiene are major concerns.

Its design includes a small, rugged stainless steel casing, which not only makes it long-lasting but also corrosion-resistant—a crucial aspect when handling condensate in extreme steam conditions.

Features of the BPT13S Thermostatic Steam Trap

Balanced Pressure Thermostatic Operation

The BPT13S works on a thermostatic capsule that expands and contracts with steam and condensate temperature. This smart response allows condensate to be discharged effectively while keeping steam in the system.

Hygienic Design for Clean Applications

This trap is specifically designed for hygienic applications, particularly in the food, pharmaceutical, and biotechnology sectors. It meets clean steam standards and ensures system sterility.

Rugged Stainless Steel Construction

Body and internals are constructed from 316L stainless steel, giving excellent corrosion resistance and longer product life even under demanding conditions.

Energy Savings

By reducing steam loss and condensate removal effectively, the BPT13S improves energy efficiency throughout the steam system. It reduces fuel use and operating expense.

Compact and Lightweight

Due to its small size, it is simple to install even under congested piping arrangements. Its compact design allows it to perform well under various load conditions without compromising on functionality.

Self-Draining and Freeze-Resistant

It has a self-draining construction, minimizing the risk of freeze damage in cold climates or shutdown conditions.

Easy Maintenance and Long Life

With minimal moving parts and a strong thermostatic capsule, the BPT13S has low maintenance and offers reliable operation over the long term.

Where is the BPT13S Steam Trap Applied?

Due to its clean construction and reliable performance, the Spirax Sarco BPT13S is widely used in:

Pharmaceutical manufacturing – for sterilizer condensate removal.

Food and beverage industries – ensuring hygiene and heat transfer in clean steam systems.

Hospitals and laboratories – utilized in autoclaves and sterilizers.

Chemical and biotech plants – for steam tracing and process heat control.

Why Choose Spirax Sarco?

Spirax Sarco has a heritage of engineering excellence and product innovation. Selecting their BPT13S steam trap is an investment in:

- Less energy waste

- Lower maintenance costs

- Sanitary and clean steam compliance

- Long-term system reliability

Reviews

There are no reviews yet.