| Attribute | Value |

|---|---|

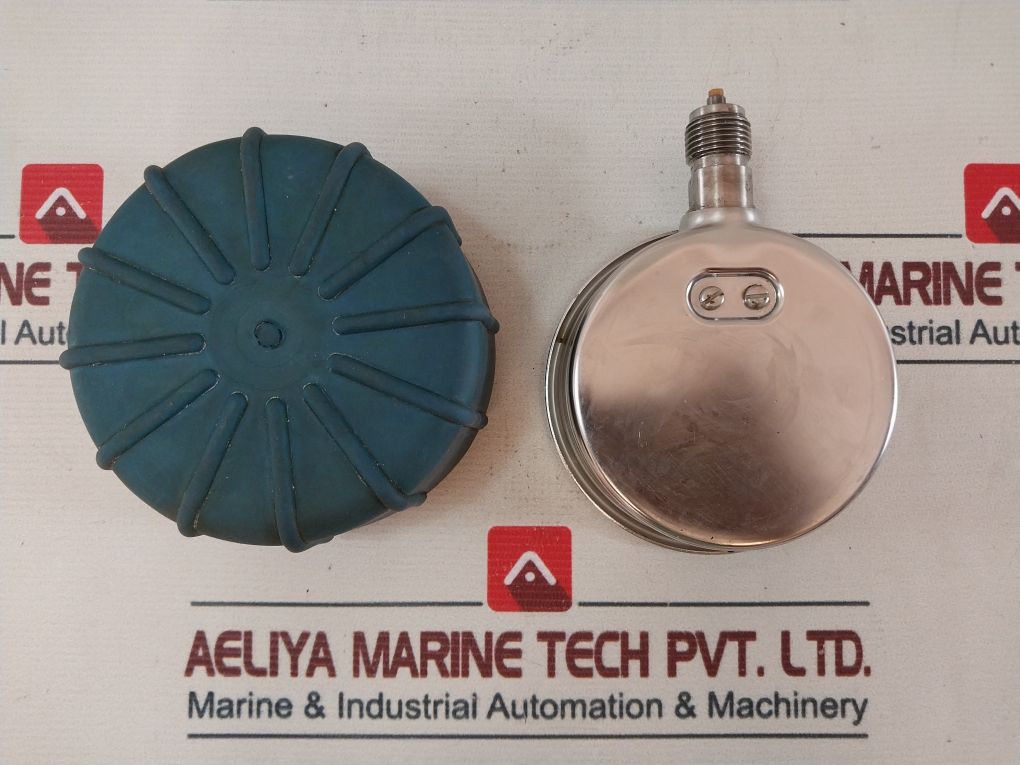

| Brand | Smf |

| Pressure Range | 0-1000 Bar |

| Pressure Range (MPa) | 0-100 Mpa |

| Accuracy Class | Kl. 1,0 |

| Weight | 1.060 Kg |

| Reference Number | 77938 |

Key Features of the SMF 0-1000 Bar Pressure Gauge

The following are some of the unique features that make this gauge a preferred choice in industrial applications:

1. Wide Measuring Range

Range: 0 to 1000 Bar / 0 to 100 MPa

This enables measurement of very high-pressure systems, which is ideal for demanding industries.

2. High Accuracy

Class: KL. 1.0

The gauge is highly accurate, which is critical for process control and safety monitoring.

3. Rugged Construction

Built to survive tough operating environments, including vibration, temperature changes, and corrosive conditions.

4. Easy-to-Read, Clear Dial

The gauge features an easy-to-read, large-diameter dial for speedy, precise readings with reduced operator error.

5. Lightweight & Compact

Weight: 1.060 Kg

Its compact size facilitates easy installation and keeps space requirements at a minimum.

6. Universal Mounting Options

Ideal for panel mounting, direct mounting, or using extra fittings as needed.

Why Use the SMF 0-1000 Bar Pressure Gauge?

Selecting the appropriate pressure gauge is essential to ensure operational effectiveness and safety. Let’s see why the SMF 0-1000 Bar model is preferable:

✓ Superb Durability

Designed to withstand high pressure and harsh industrial conditions, guaranteeing extended service life.

✓ Long-Lasting Performance

Constant accuracy despite varying temperatures and vibration factors.

✓ Minimal Maintenance

The heavy-duty design reduces the necessity of repetitive calibration or maintenance.

✓ Cost-Saving

Provides great precision and durability for a competitive price, thus offering great value.

Applications

The SMF 0-1000 Bar Pressure Gauge is utilized in a wide array of industries, which include:

1. Oil & Gas

Pressure monitoring of drilling rigs, pipelines, and refineries.

2. Hydraulic Systems

Proper operation and safety of high-pressure hydraulic equipment.

3. Chemical Processing

Monitoring and controlling pressure in reactors, pumps, and chemical lines.

4. Power Generation

Monitoring steam and boiler pressure in power stations.

5. Manufacturing

Regulation of pressure in heavy machinery, injection molding machines, and presses.

6. Marine & Offshore

Monitoring shipboard systems and subsea operations where reliability is paramount.

Reviews

There are no reviews yet.