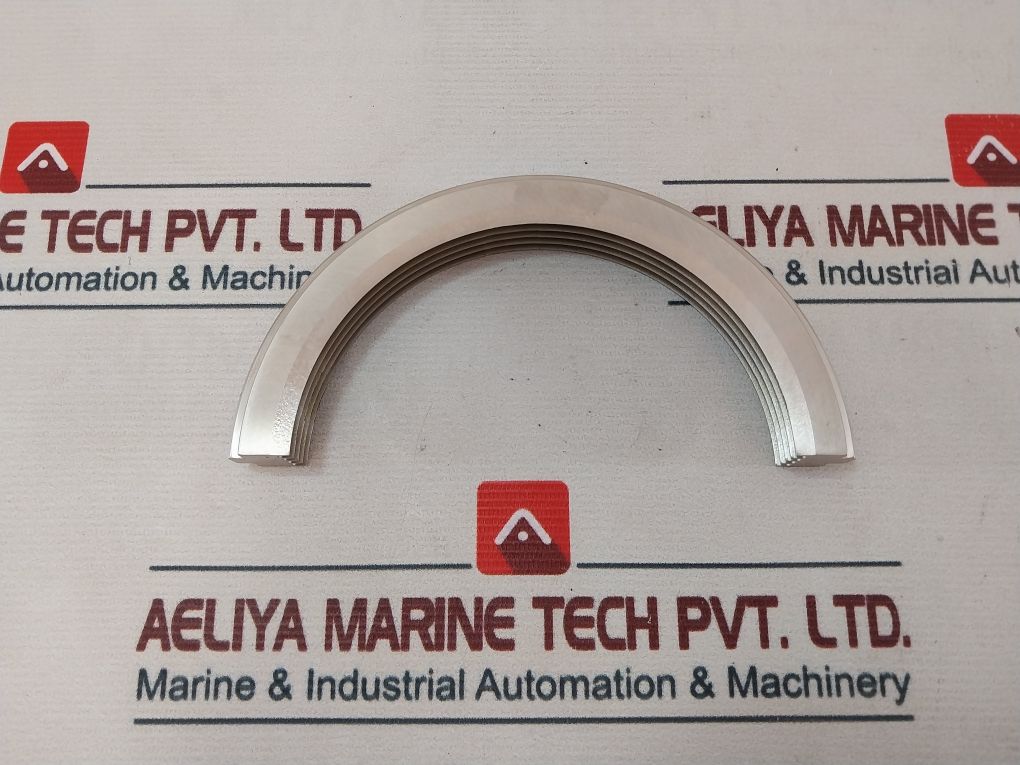

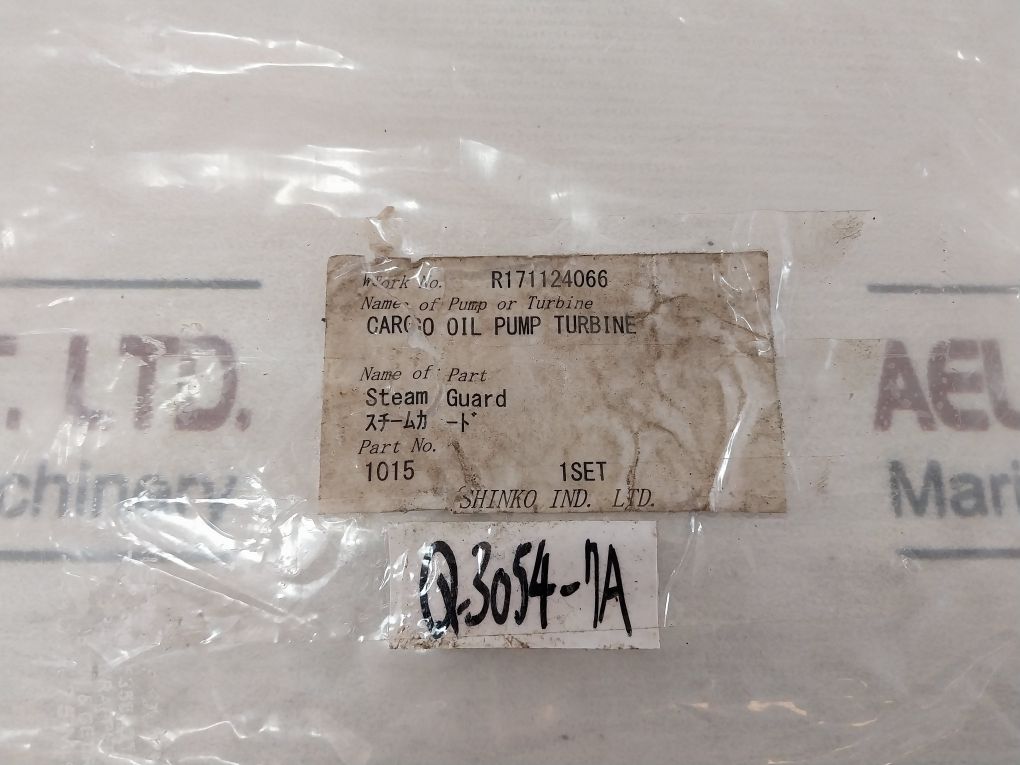

| Attribute | Value |

|---|---|

| Manufacturer | Shinko Ind. Ltd. |

| Name Of Pump Or Turbine | Cargo Oil Pump Turbine |

| Name Of Part | Steam Guard |

| Part No. | 1015 |

| Additional Part No. | Q-3054-7a |

| Weight | 1.360 Kg |

| Ref No | 77747 |

What is the Shinko 1015 Steam Guard?

Shinko 1015 Steam Guard is a high-performance steam management system that efficiently monitors and regulates steam pressure. It assists industries in maximizing their energy consumption while avoiding dangerous steam-related accidents. With innovative technology and accuracy engineering, it is one of the safest solutions for steam control.

Key Features of Shinko 1015 Steam Guard

Advanced Pressure Control – Provides accurate steam pressure control to ensure efficiency and avoid energy wastage.

High Durability – Constructed using heavy-duty materials, it is resistant to high temperatures and pressure fluctuations.

Increased Safety Mechanisms – Integrated with automatic safety shutdown mechanisms in the event of irregular steam conditions.

User-Friendly Interface – Simple-to-read interface and easy-to-use control mechanisms for hassle-free operation.

Energy Efficiency – Saves fuel and operation costs by streamlining steam use.

Low Maintenance Requirement – Built to operate with minimum maintenance, minimizing downtime and service expenses.

Advantages of Using Shinko 1015 Steam Guard

1. Enhanced Safety in Industrial Processes

Accidents involving steam are disastrous. The Shinko 1015 Steam Guard eliminates risks by sensing unusual steam pressure irregularities and automatically compensating or shutting down the system, if required.

2. Energy and Cost Savings

By managing steam flow effectively, this system minimizes wastage of unnecessary steam, resulting in reduced energy expenses and more efficient industrial processes.

3. Increased Equipment Lifespan

Unregulated steam pressure can cause industrial equipment to deteriorate over time. With the Shinko 1015 Steam Guard, steam systems run under ideal conditions, extending the lifespan of boilers and other steam-based machinery.

4. Industry Standards Compliance

Businesses that utilize steam are required to meet safety and operational requirements. This system guarantees that companies are in line with regulations, evading legal issues and safety infractions.

Uses of Shinko 1015 Steam Guard

Shinko 1015 Steam Guard is applied in most industries due to its diverse uses. These include:

Power Plants – Used in regulating steam pressure in turbines and boilers.

Food Processing – Guarantees safe use of steam in cooking, sterilization, and packaging.

Textile Industry – Provides continuous steam pressure to process and dye fabric.

Pharmaceuticals – Helps keep the environment sterile through accurate control of steam.

Chemical Industry – Helps regulate steady temperatures to be used during chemical reactions.

Reviews

There are no reviews yet.