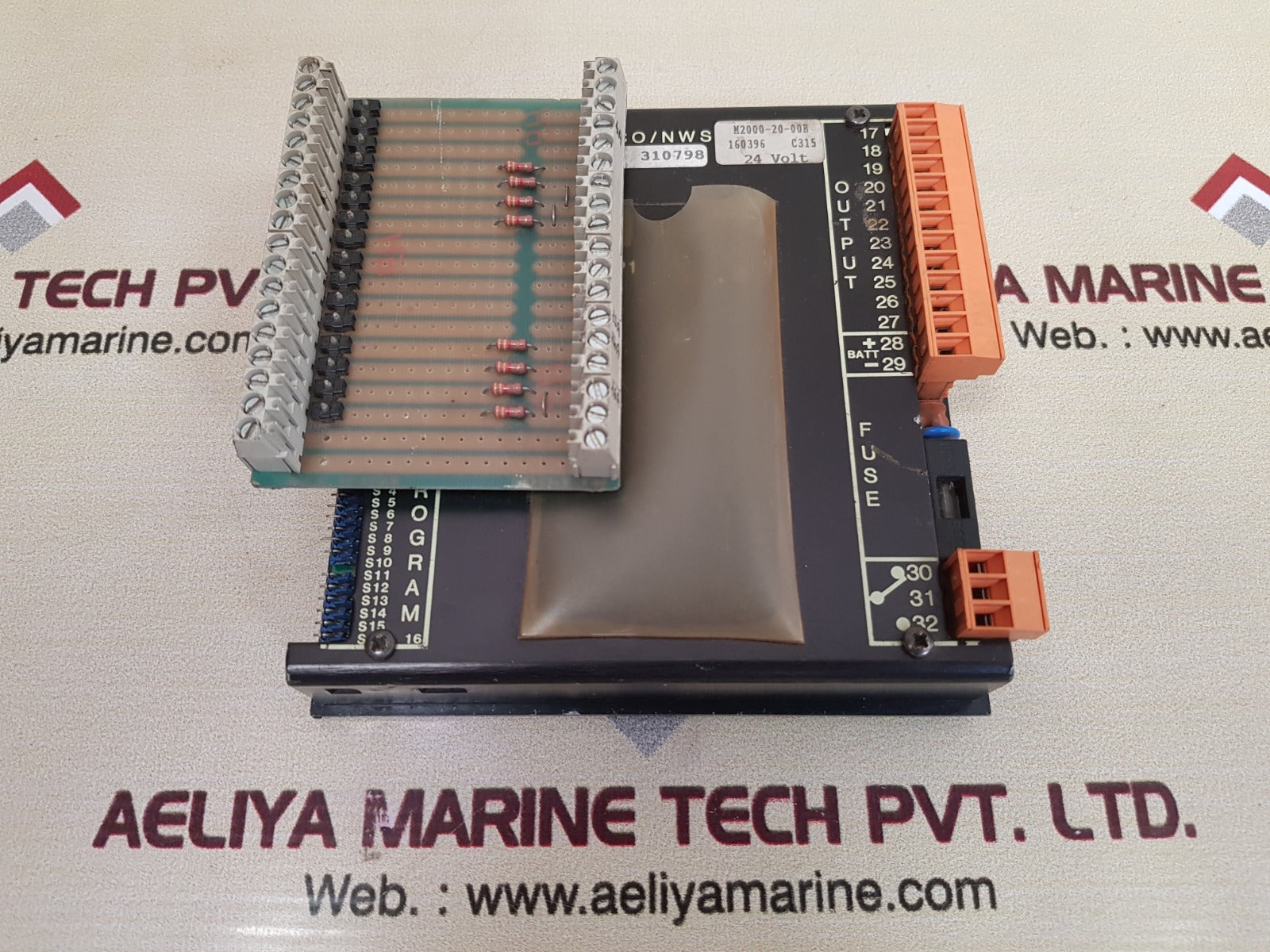

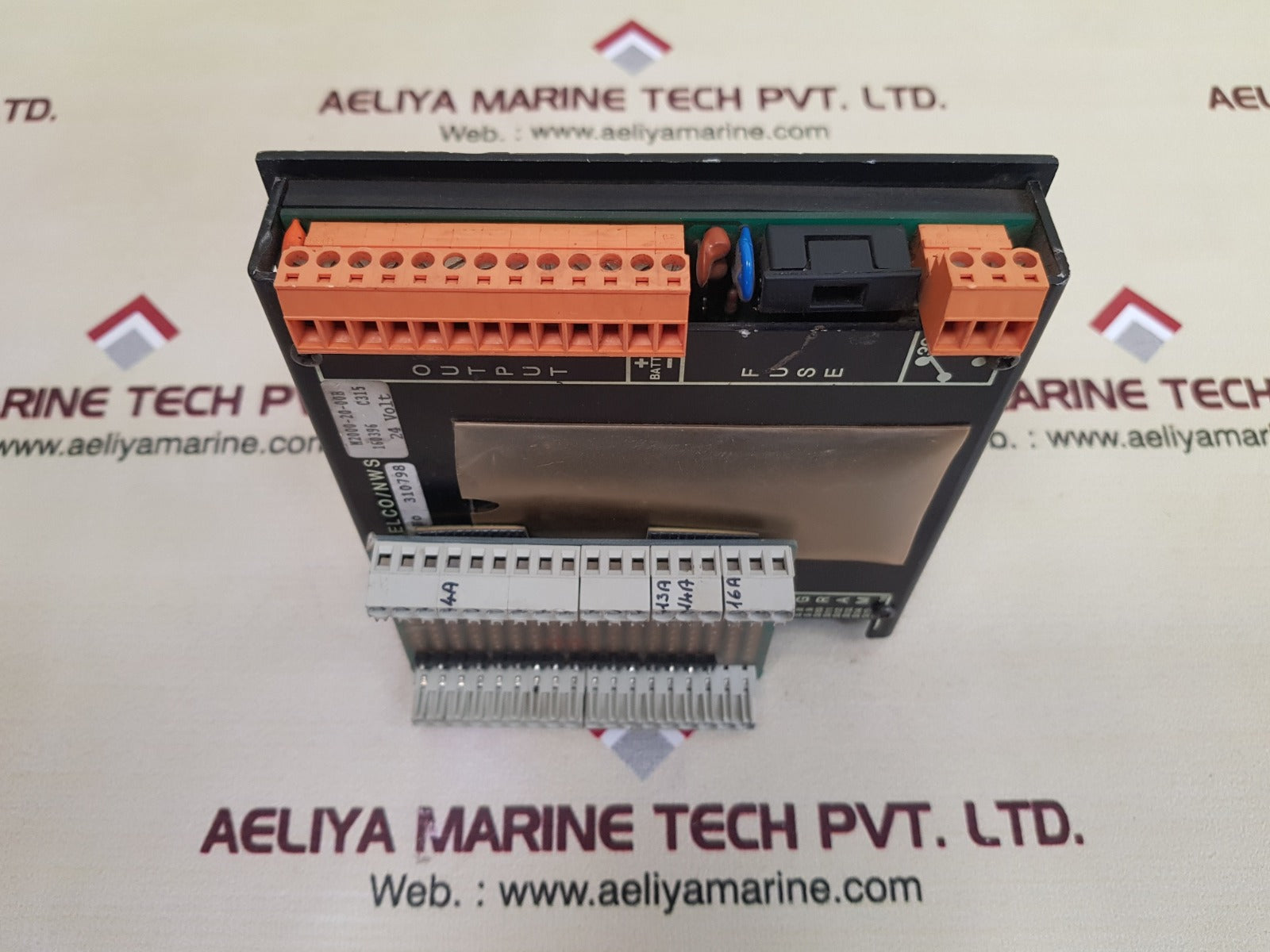

| Attribute | Value |

|---|---|

| Brand | Selco/NWS |

| Model | M2000-20-00B |

| Type | Controller |

| Part Number | 160396 C315 |

| Voltage | 24 Volt |

| Serial Number | No 310798 |

| Weight | 582 gm |

What is the Selco M2000-20-00B Engine Controller?

Selco M2000-20-00B is a smart engine controller designed to offer robust monitoring, protection, and automation for diesel as well as gas engines. Selco M2000-20-00B finds extensive use in industries wherein engines are indispensable, such as power plants, marine, as well as industrial machinery.

Through its rugged construction and high-end functionality, this controller provides the best possible engine performance by constantly checking important parameters like temperature, oil pressure, speed, and load conditions.

Features of Selco M2000-20-00B

1. Real-Time Monitoring & Protection

The M2000-20-00B continuously monitors engine speed, oil pressure, coolant temperature, and other critical parameters. As soon as any parameter crosses the safe limit, the controller triggers alarm or switches off the engine to avoid damage.

2. Multi-Function Display & User Interface

The controller is equipped with an easy-to-use LCD display that gives real-time information and system status. The user interface makes it easy for operators to easily set up settings and track performance without hassle.

3. Automatic Engine Start/Stop

One of its best features is its capacity for automatically starting and stopping the engine depending on predetermined conditions. This is especially advantageous in unmanned power systems where automation is essential.

4. Remote Monitoring & Control

Equipped with high-level communication interfaces, the Selco M2000-20-00B can be interfaced with remote monitoring systems, enabling users to monitor the engine performance remotely. This is important for application in offshore power systems, remote generators, and marine ships.

5. Multiple Alarm & Protection Functions

The controller comes with inherent alarms and protection functions, such as:

- High coolant temperature shutdown

- Low oil pressure shutdown

- Over-speed and under-speed protection

- Battery voltage monitoring

- Fuel level monitoring

6. Support for Various Types of Engines

The Selco M2000-20-00B supports both diesel and gas engines, which makes it a highly versatile option for use in a broad variety of applications.

7. Heavy-Duty & Long-Lasting Construction

Designed to operate in hostile environments, the M2000-20-00B boasts a heavy-duty enclosure that is capable of withstanding vibration, humidity, and extreme temperatures.

Applications of Selco M2000-20-00B

The adaptability of this controller makes it applicable to many different applications, including:

1. Power Generation

- Applied in hospital, data center, and commercial building backup generators.

- Provides stable and reliable operation in case of power outages.

2. Marine Industry

- Controls and monitors marine propulsion engines and generator sets.

- Prevents engine overheating, over-speeding, and low oil pressure.

3. Industrial Machinery

- Assists in controlling heavy-duty machinery in construction, mining, and manufacturing industries.

- Offers automated start/stop capabilities to increase operational efficiency.

4. Remote & Unmanned Power Systems

- Perfect for remote and off-grid areas where there is no hand operation possible.

- Enables auto start/stop on demand to minimize fuel utilization and maintenance charges.

Advantages of Utilizing the Selco M2000-20-00B

1. Enhanced Engine Life

Through constant supervision and safeguarding of the engine against harsh situations, the M2000-20-00B prevents wear and tear well before time and prolongs the life of the engine.

2. Lower Maintenance Charges

With its advanced alert system, operators are able to identify problems early, minimizing surprise breakdowns and expensive repairs.

3. Enhanced Efficiency

The controller maximizes fuel usage by keeping the engine at its most efficient capacities, lowering operational expenses.

4. Increased Safety & Protection

The integrated safety features avoid major engine failures, safeguarding equipment and personnel.

5. Remote Access & Automation

With remote monitoring features, companies are able to cut labor expenses and control multiple engines from one place.