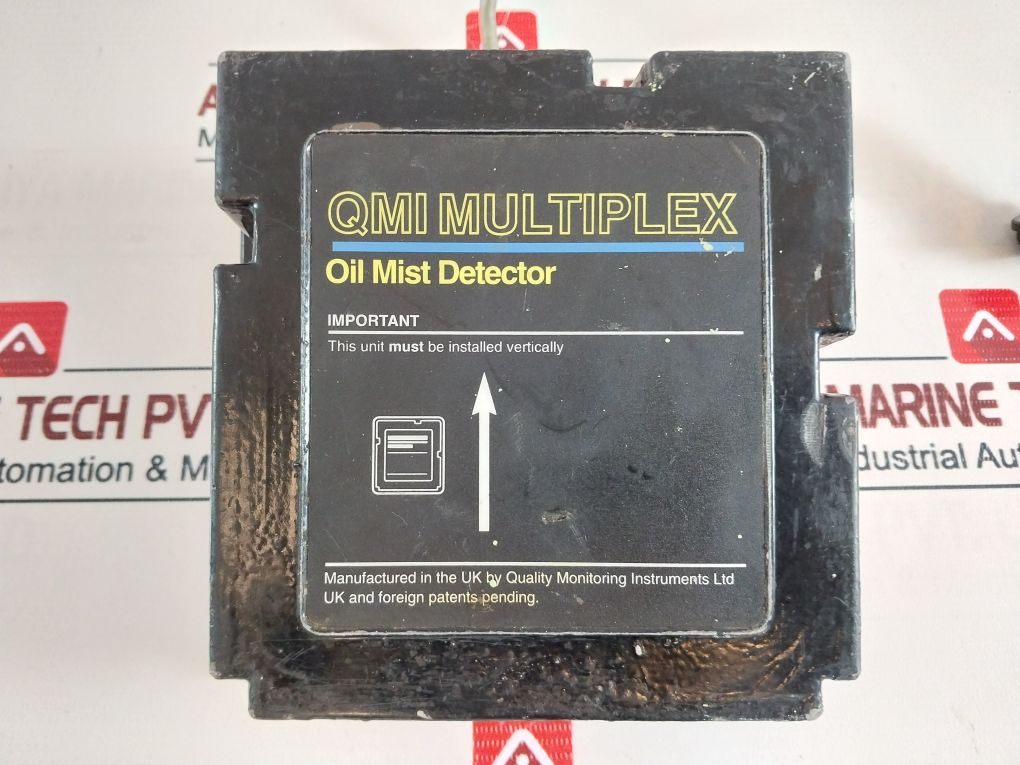

| Product | Quality Monitoring Instruments Oil Mist Detector |

|---|---|

| Manufacturer | Quality Monitoring Instruments Ltd |

| Brand | QMI Multiplex |

| Type | Oil Mist Detector |

| Origin | Manufactured in the UK |

| Weight | 2.550 Kg |

| Ref No | 74175 |

Understanding Oil Mist Detectors

Oil mist detectors are devices meant to detect and track the presence of oil mist in enclosed rooms. There are common locations for such equipment, such as machinery rooms and engine rooms. The presence of oil mist is possibly indicative of leaks or malfunctioning pieces of equipment. If it is allowed to persist, it could lead either to hazards in the form of fire, which might destroy an engine or cause its full destruction, or to explosions. Therefore, oil mist detection should be performed before they become potential safety hazards in industrial areas like marine, power plants, and manufacturing.

How Oil Mist Detectors Work?

Oil mist detectors work by continuously sampling the air inside a closed environment. Here is how it works:

Air Sampling: The oil mist detector continuously pulls the air from the detected environment.

Optical Sensing : Air flows over an optical sensor that monitors the scattering of light produced as a result of oil droplets.

Alarm Activation: The equipment automatically activates an alarm whenever the concentration of oils crosses a specified limit, and there is some leeway for speedy adjustments.

Detectors with such technology are equipped with the state-of-the-art sensors, which monitor live trends. It is, therefore, very feasible to make them a component of comprehensive safety arrangements that ensure proper functioning as well as prompt action.

Key Advantages of Oil Mist Detectors

Early Detection: Oil mist detection can identify the presence of oil mist preventing any harm that could be caused to machinery, as well as minimizing the danger potential of a fire and explosions.

Extended Equipment Life: With optimum levels of oil and no leakage, oil mist detectors contribute to increased equipment life along with low maintenance costs.

Compliance with Regulatory Requirements: Many industries enforce strict safety standards. An oil mist detector ensures compliance with these regulations, and hence, the workplace becomes even safer.

Cost Saving: Quality monitoring devices, including oil mist detectors, will pay off in the long term since they will help prevent expensive maintenance and machines or facilities with a duration of possible downtime.

Application of Oil Mist Detector

Oil mist detectors do find applicability in every industry since they can guarantee high effectiveness and reliability:

Marine Industry: Especially engines and enclosed spaces in ships have a high tendency to oil mist formation. In this way, oil mist detectors offer safe navigation through warning the crew regarding dangerous conditions.

Power Generation: In many power plants, engines and turbines are monitored to prevent any type of accident thus, oil mist detectors must be taken in industries as a safety system.

Manufacturing: In heavy machine factories, such detectors are contemplated to ensure the air quality and to protect leakage-caused fire

Automotive: In the engine test houses, oil mist detectors detect leakage which ensures proper performance and security of the engine.

Why prefer quality monitoring instruments from Aeliya Marine Tech?

Aeliya Marine Tech is concerned with the fact that safety is critical in most industries. Our oil mist detectors are designed and produced for high accuracy, reliability and efficiency. We work tenaciously to guarantee both quality and satisfaction for customers through solutions suited to the regulatory requirements of industries and yield optimum safety.

Reviews

There are no reviews yet.