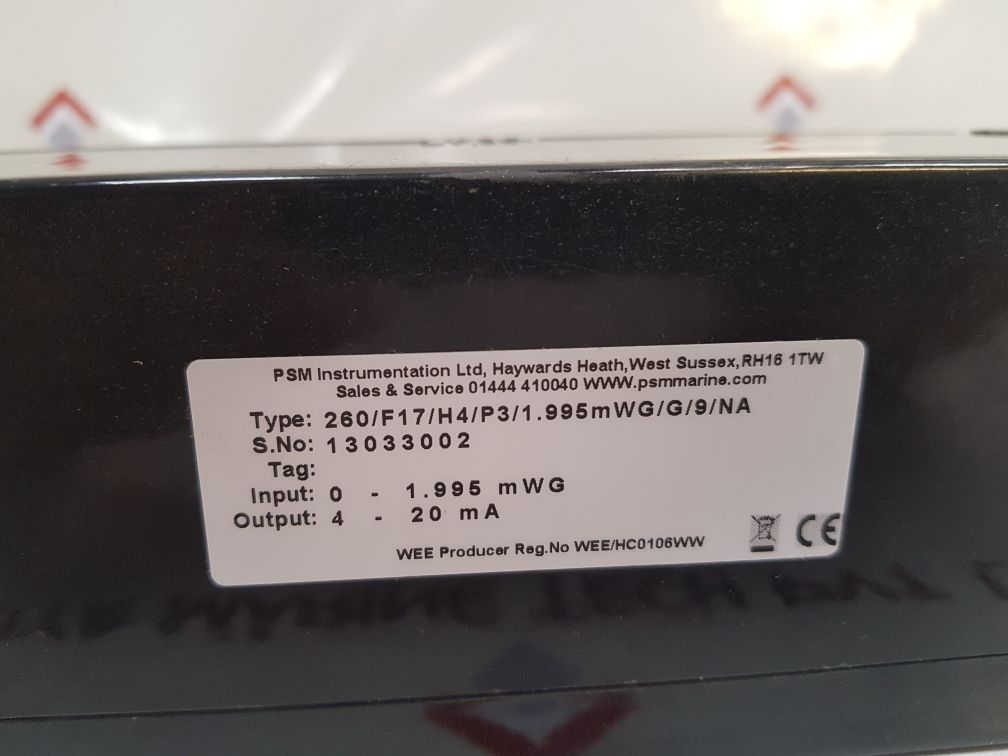

| Attribute | Value |

|---|---|

| Company | PSM INSTRUMENTATION LTD |

| Type | 260/F17/H4/P3/1.995MWG/G/9/NA |

| Input | 0-1.995 MWG |

| Output | 4-20 MA |

| Weight | 710 GM |

| Condition | NEW 1 PCS |

| Reference Number | 37279 |

What is PSM Instrumentation?

PSM instrumentation is the measurement and control tool and system of industrial processes with safety and efficiency. It has been found essential in industries, such as power generation, manufacturing, and chemical processing, that require accurate measurement and safety considerations.

The specific model, 260/F17/H4/P3/1.995MWG/G/9/NA, is one of the top-of-the-line solutions designed to deliver high-performance standards. Let’s break down some of its key features and see why it is the game-changer.

Key Features of the 260/F17/H4/P3/1.995MWG/G/9/NA Model

1. Advanced Measurement Precision

This instrumentation has unparalleled precision that can measure variables with minimal error margins. Pressure, flow, or temperature – whatever the measurement, the 260/F17/H4/P3 ensures accurate data for critical decision-making.

2. Robust Construction

Designed for industrial environments, this instrument is built from high-grade materials that resist corrosion, heat, and mechanical stress, which means it can last longer and work more reliably.

3. Energy Efficiency

Operating at 1.995MWG, this model maximizes energy consumption but still offers constant performance. It is especially suitable for industries looking to cut energy costs without losing productivity.

4. Integration and Compatibility

The system is designed to be integrated with the existing industrial setup. The compatibility of the system with several software platforms allows operators to handle the processes easily and flexibly.

5. Overall Safety Measures

This model is designed with safety at its core. With fail-safe mechanisms, it minimizes risks associated with system failures and protects personnel and equipment.

Applications of PSM Instrumentation

The 260/F17/H4/P3/1.995MWG/G/9/NA model is applied in various industries:

Energy Sector:

- It is used in power plants to monitor and control energy generation processes.

- It ensures compliance with regulatory standards.

Manufacturing:

- It enhances automation and process efficiency in production lines.

- It minimizes downtime through real-time monitoring.

Chemical Processing:

- Critical to the maintenance of safe operating conditions for chemical reactions.

- Detects anomalies before they are amplified.

Aerospace and Defense:

- It is critical in the testing and servicing of high-technology equipment.

- Guarantees accuracy in environments where an error can be disastrous.