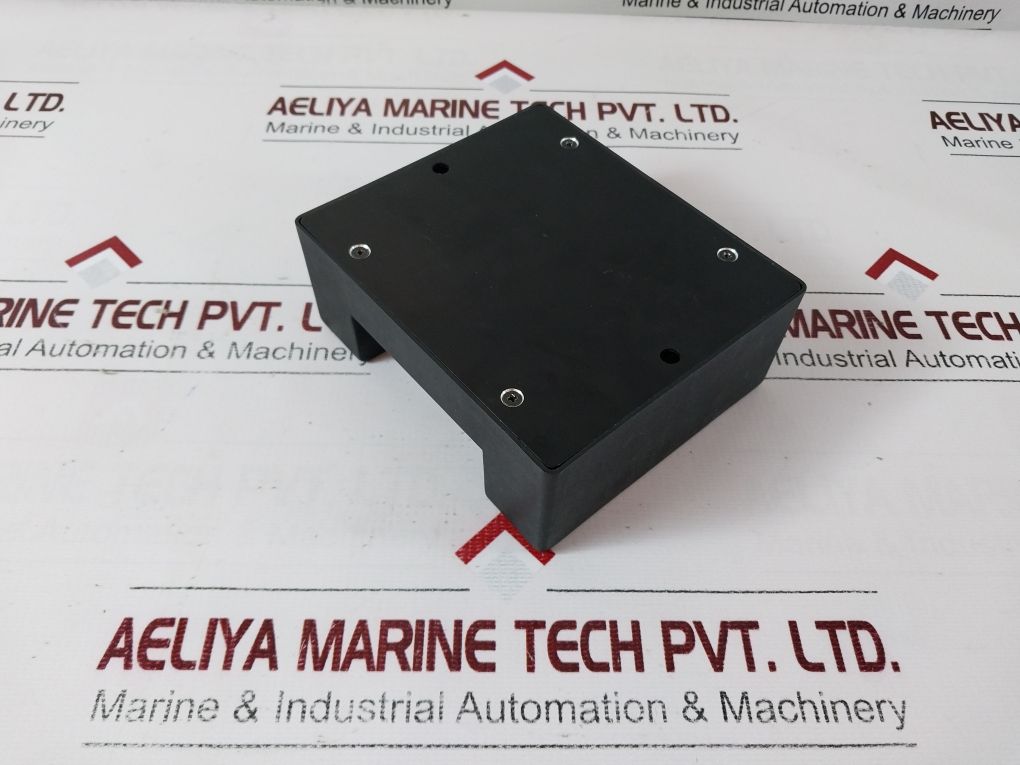

Proces-data G010n603.b01 Tacho Unit

Made By Proces-data

Iph

Tacho Unit

G010n603.b01/1653530-7

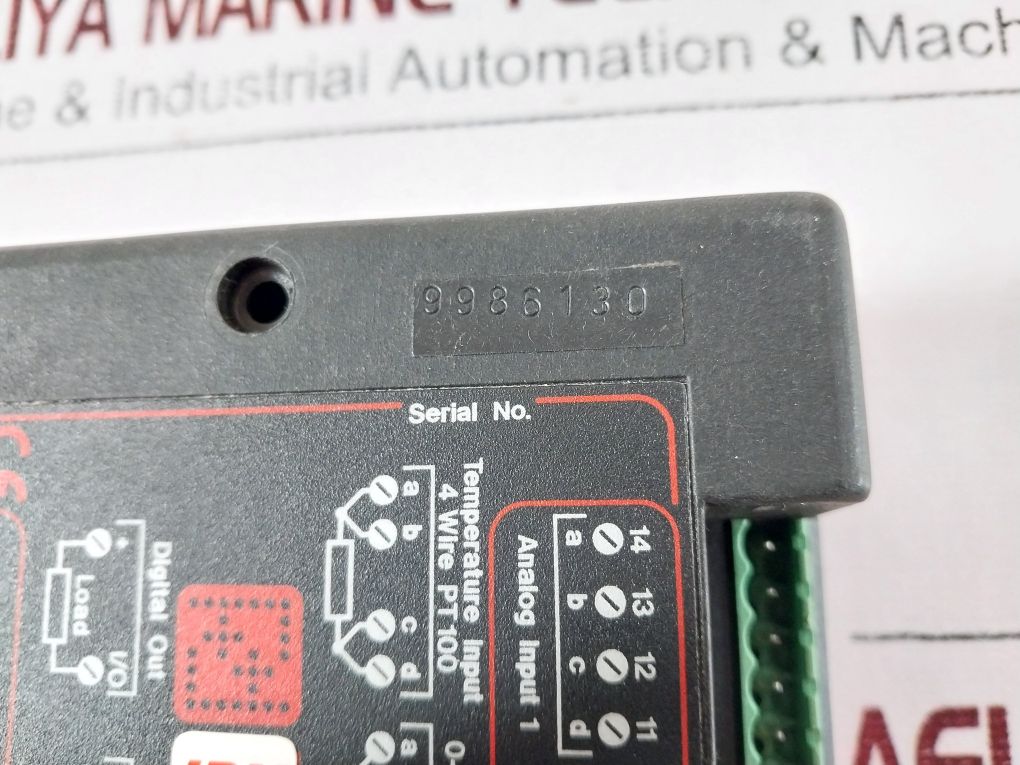

24 V Dc

4 Wire Pt100

0-20/4-20 Ma

0-100mv

608145

Made In Denmark

Weight : 340 Gm

Ref No : 69519

What is a Tacho Unit?

A tacho unit or tachograph, in a very basic manner, is an instrument that measures and records the speed and movement of a machine or a vehicle. Tachographs were initially designed to monitor speeds and time periods of trips for commercial vehicles, especially in transportation, for purposes of safety and compliance. Today, these devices serve various industries where data regarding movement, speed, and time are relevant.

The Proces-data G010N603.B01 tacho unit is a professional-grade machine dedicated to niche industrial applications. The device enables the reading of rotational speed, direction, and even the operating hours of any given machinery component, so it is highly applicable in scenarios where monitoring efficiency and preventing mechanical breakdowns is a prime challenge.

Main Features of the Proces-data G010N603.B01 Tacho Unit

Accuracy

The G010N603.B01 has been designed to critically measure rotational speed. This instrument is not only used on motors and pumps in the industrial setting but also in vehicles for ensuring that the speeds are kept within the utmost acceptable performance threshold.

Data Logging

The great feature of the Proces-data tacho unit is that it allows data logging over time, so you can monitor your historical performance and trace where certain trends may be located and when some equipment might not be performing well or at risk of failure.

User-Friendly Interface

This unit carries the advanced features in a user interface with ease, making it easy to set up and integrate into other existing systems. Users can easily program and retrieve data without needing significant training for technicians or operators.

Durable and Reliable

The G010N603.B01 is designed for industrial working conditions. It is sturdy and strong but simultaneously light, while it offers good performance under tough working conditions, such as extreme temperature, dust, or vibrations. Its reliability places it above most manufacturing, mining, and transport industries.

Real-Time Monitoring

The tacho unit is able to monitor data in real time. It means that if a machine starts running abnormally, for instance, if it is losing speed or going out of its normal direction, alerts will be triggered and could be intervened upon quickly to avoid possible damage or loss of time.

Compliance and Safety

In industries where safety and compliance are non-negotiable, the tacho unit ensures that machines are operating within legal and safe parameters. For example, fleet management involves tachographs, in which it is mandatory to ensure that drivers do not exceed the allocated hours or speed limitable. Its use for industrial machinery is helpful for maintaining operational safety and reduces the risk of accidents because of mechanical failures.

How Does It Work?

The Proces-data G010N603.B01 Tacho Unit is fitted with the ability to attach sensors to parts that rotate when in motion. The sensors determine the rotation speed-often expressed in RPMs or rotations per minute, then relay that data to the tacho unit. The unit then evaluates this information against set limits, benchmarks, or other standards.

The tacho unit monitors a motor designed for conveyor belts in a factory, it effectively monitors the speed at which the motor is running. The tacho unit will send an alarm in case of the motor running faster or slower. The functionality is essential in the prevention of overloading and wear and tear in a system to maintain its health altogether.

By using the tacho unit in fleet management, it tracks the speed of the vehicle and records the time span that the driver spent on the road. The information is indispensable in terms of ensuring that there is compliance with regulations and the safety of the drivers, as it makes sure that they maintain the right speed and can take rest time in case of need.

Advantages of Proces-data G010N603.B01 Tacho Unit

Increased Efficiency

In such a way, it can be improvised continuously, and the chances of downtime can be avoided. Moreover, the life period of the equipment can also be increased. For the continuous production units of any business firm, this unit can be taken to be the most efficient.

Predictive Maintenance

The data logging function enables predictive maintenance. Instead of reacting only after breakdowns have happened, it is possible to predict when a component might fail and correct the situation before the problems happen. This means no additional cost and time into the repairs .

Safety and Compliance

Where the safety standards are strict for industries, the tacho unit keeps things inline with the standards. It can offer the documentation and records required in case of inspection, thus ensuring that it won’t be charged with fines or some other legal issues.

Cost Savings

The tacho unit saves on the cost of machinery breakdown when it is operating out of the parameters. With predictive maintenance, you can schedule repairs when business is off-peak rather than in peak times during unscheduled downtime. This way, revenue loss is not incurred.

Better Decision Making

The data generated by the tacho unit helps managers and decision-makers know the operative health of the machinery. As a result, this enables them to make informed decisions on upgrading equipment, shifting maintenance schedules, and operational strategies.

Applications of the Proces-data G010N603.B01 Tacho Unit

The applications of the tacho unit will depend on its versatility; hence it can be applied in a range of industries. Among the common applications is:

Manufacturing Plants: To monitor the speed of motors, conveyor systems, and pumps.

Mining Operations: It is applied in the mining operations to trace out heavy machinery and prevent damage or failure due to excessive wear.

Logistics and Transportation: In logistics and transport, it tracks fleets to check out whether they are following the driving regulations or not.

Energy Sector: It is applied in the energy sector to trace out the turbines and generators that are present in the electricity power plants.

Reviews

There are no reviews yet.