| Attribute | Value |

|---|---|

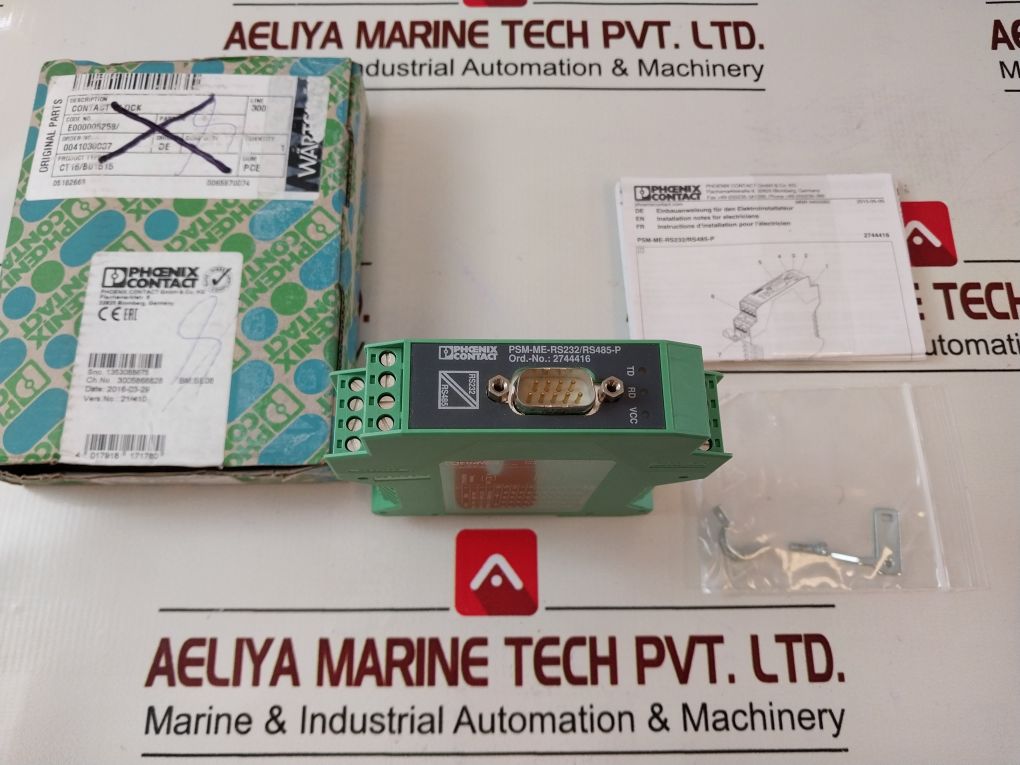

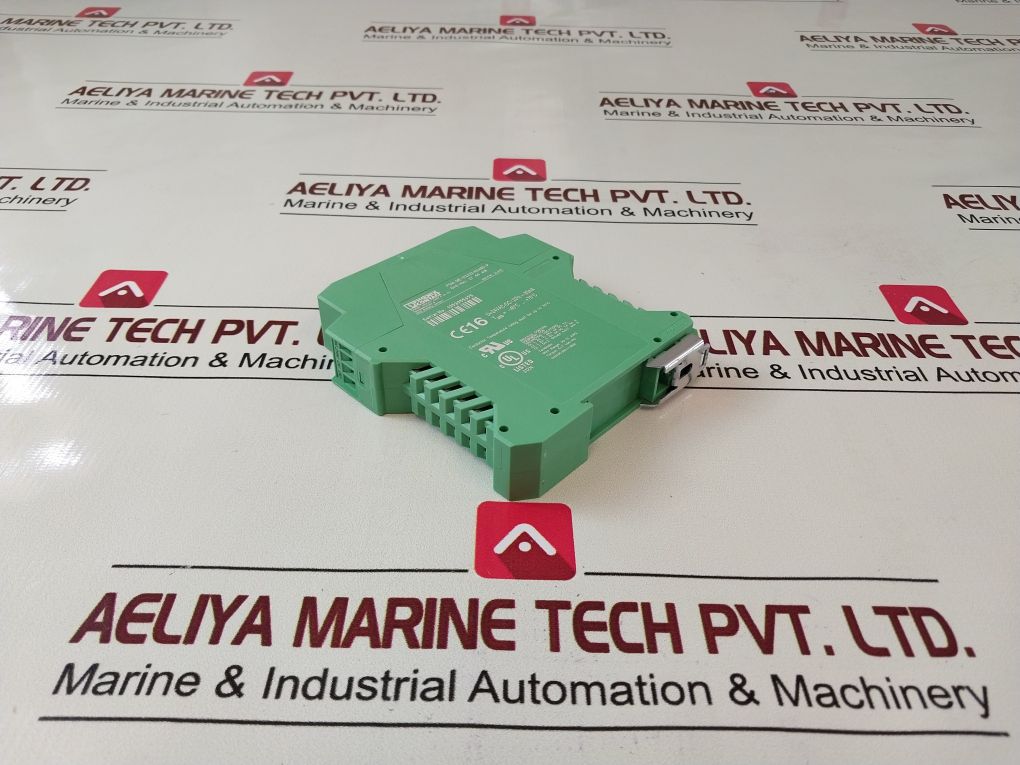

| Manufacturer | Phoenix Contact GmbH & Co. KG |

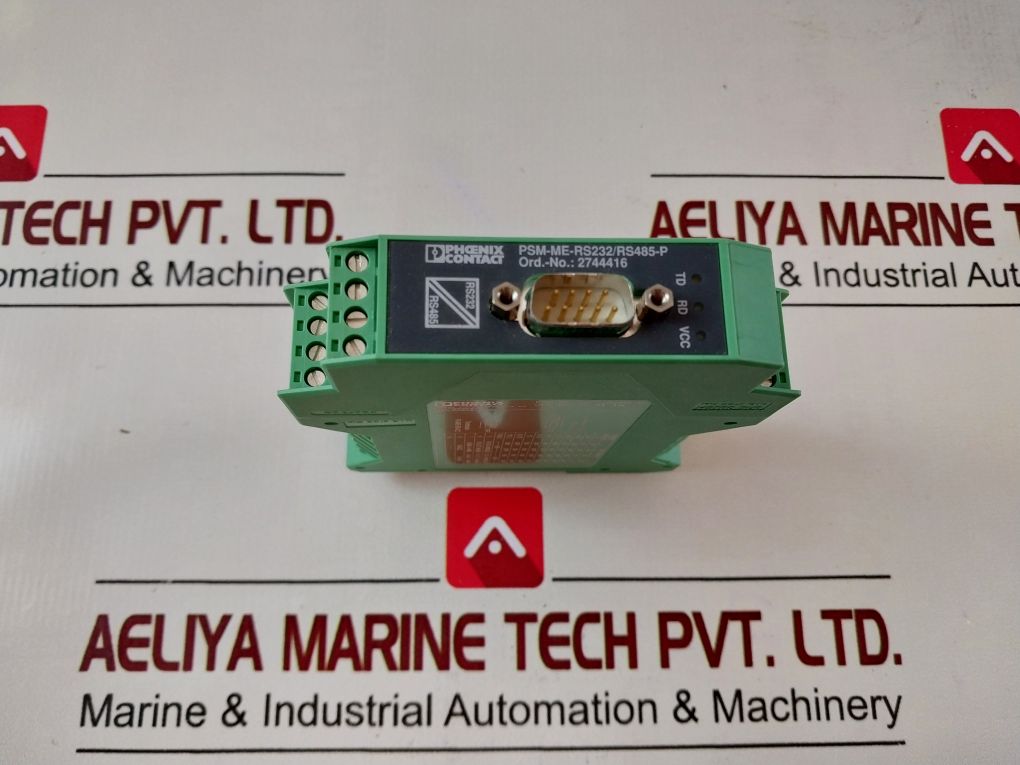

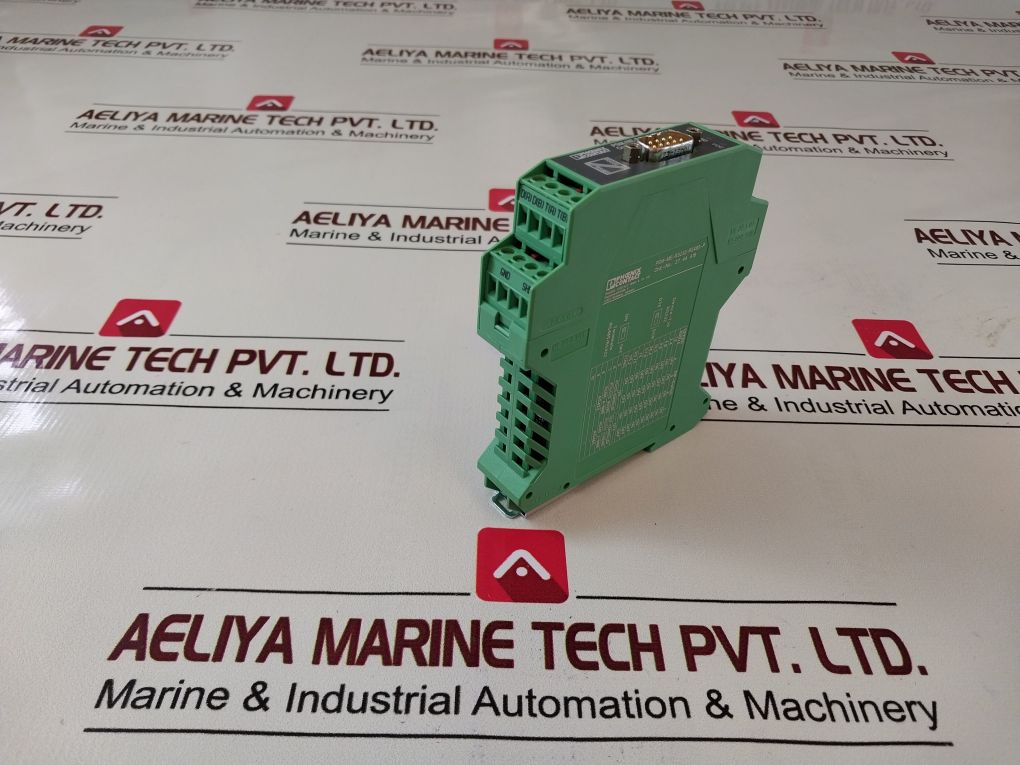

| Model | PSM-ME-RS232/RS485-P |

| Order No / Art.-Nr. | 27 44 416 |

| HW / FW | 21 / 410 |

| Input Voltage | 24V AC/DC ±20% ~ 85mA |

| Operating Temperature | -40°C … +70°C |

| Classifications | Cl. I, Zn. 2, AEx nA IIC T4 Cl. I, Zn. 2, Ex nA IIC T4 Gc X Cl. I, Div. 2, Groups A, B, C and D |

| Wire Range | 30-12 AWG |

| Torque | 5–7 lbs-ins. |

| CH. No. | 3005868828 BM: SE08 |

| Barcode | 4 017918 171780 |

| Made In | Germany |

| Weight | 200 gm |

| Condition | New (1 pcs) |

| Reference No | 59027 |

What is the Phoenix Contact PSM-ME-RS232/RS485-P?

This RS-232 to RS-485 interface converter is designed to translate RS-232 signals into RS-485, so it’s perfect for situations where you require long-distance communication or multi-point connection. RS-232 is used extensively but has distance and speed limitations. RS-485 allows longer cable lengths and multi-drop connections, which is precisely what most industrial networks need.

Key Features

Accurate Signal Conversion: Translates RS-232 to RS-485 and vice versa without additional power supply in certain setups.

Industrial-Strength Construction: DIN rail-mountable with a heavy-duty casing, it’s designed for harsh conditions.

Seamless Communication: Software-free configuration—simply plug and play.

Galvanic Isolation: Shields your equipment from voltage spikes and ground loops.

High Compatibility: Compatible with PLCs, HMIs, sensors, and other industrial equipment.

Why Use an Interface Converter?

Legacy devices tend to utilize RS-232, while new devices or centralized control systems use RS-485. Rather than replacing existing older devices, which can be expensive and complicated, the Phoenix Contact converter provides a straightforward bridge between the two standards. This enables data sharing, integration, and control in the network—without a complete system redesign.

Advantages in Industrial Environments

Cost-Effective Integration

Prevent costly upgrades by allowing older RS-232 devices to talk to newer RS-485-based systems.

Better Signal Integrity

RS-485’s differential signaling allows data to travel farther without loss—ideal for big factory floors.

Greater Flexibility

With multi-point connection support, RS-485 enables multiple devices to talk on one network.

Less Downtime

With easy setup and durable construction, this converter eliminates the risk of failure in mission-critical applications.

Applications

Factory Automation

Integrating legacy sensors and control units with contemporary PLCs.

Building Management Systems

Merging legacy HVAC or lighting systems with centralized controllers.

Energy Monitoring

Enabling communication between older meters and newer data acquisition systems.

Transportation and Rail

Providing robust data flow in vehicles or station automation systems.