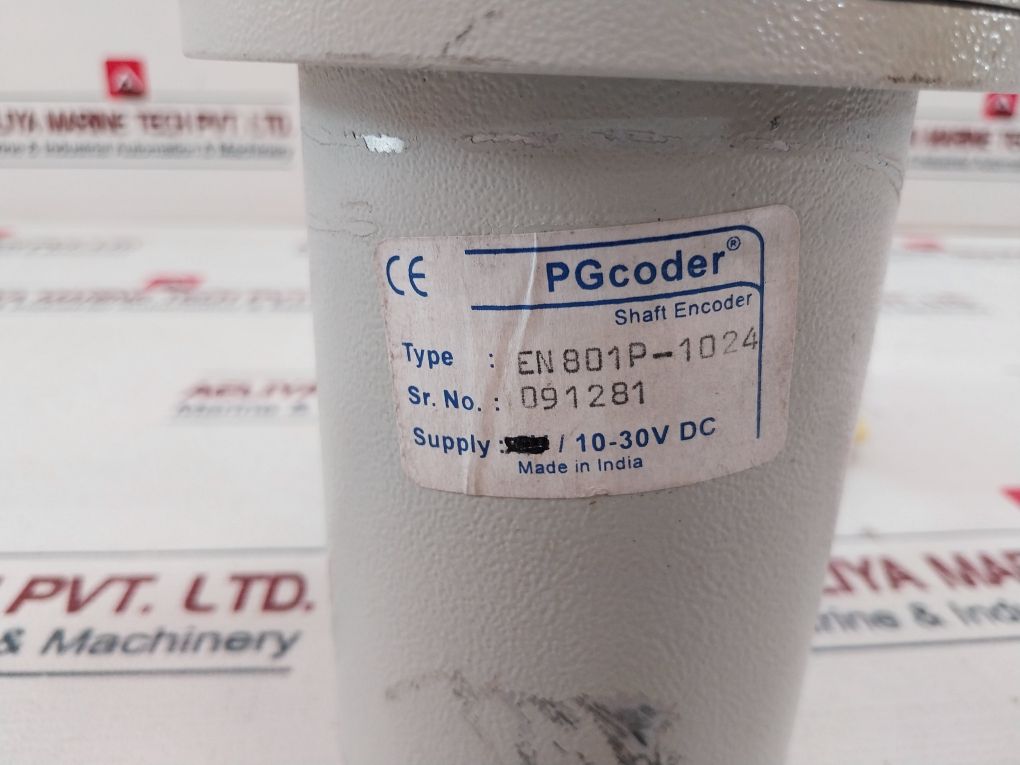

Pg Coder En801p-1024 Shaft Encoder 10-30v Dc

Pg Coder

Shaft Encoder

Type: En801p-1024

Supply: 10-30v Dc

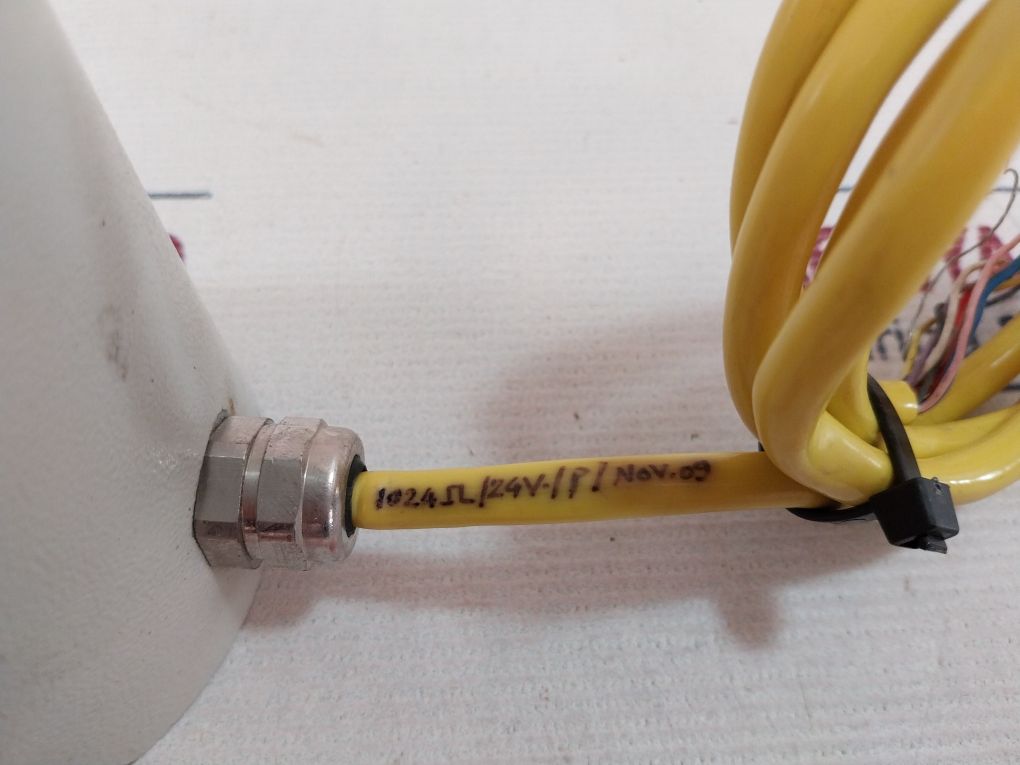

1024 Ohm/24v-/p/

Made In India

Weight : 1.730 Kg

Ref No : 82264

Product Overview

The PG Coder EN801P-1024 Shaft Encoder is a highly reliable and versatile electronic component designed for various industrial applications. This precision instrument, produced by PG Coder, serves a crucial role in machinery and systems by providing accurate position and speed feedback. In this comprehensive product description, we will explore the technical details, functionality, and advantages of the PG Coder EN801P-1024 Shaft Encoder.

How Does the Product Work?

The PG Coder EN801P-1024 Shaft Encoder operates on a fundamental principle of encoding rotational or linear movements into electrical signals. Its functionality can be summarized as follows:

- Position Sensing: This encoder precisely detects the position of a rotating or linearly moving shaft and converts it into electrical signals.

- Signal Generation: It generates a series of pulses, typically in quadrature, which can be used to determine both position and speed.

- Voltage Supply: The encoder operates within a voltage supply range of 10-30V DC, making it compatible with a wide range of industrial setups.

- High Resolution: With 1024 pulses per revolution (PPR), this encoder provides fine resolution for accurate position feedback.

When Should Someone Use the Product?

The PG Coder EN801P-1024 Shaft Encoder is an ideal choice in various scenarios, including:

- Position Control: Use it when precise control of position is crucial in machinery and automated systems.

- Speed Control: Employ it in applications where accurate speed monitoring and control are essential.

- Automation: Incorporate it into industrial automation systems, robotics, conveyor systems, and more.

Where Should Someone Use the Product?

This shaft encoder is suitable for a wide range of industrial applications, such as:

- Manufacturing: Utilize it in manufacturing processes where precise positioning and speed control are critical.

- Material Handling: Apply it in conveyor systems and material handling equipment for reliable feedback.

- Robotics: Integrate it into robotic arms and automated machinery to ensure accurate movements.

How to Use?

Using the PG Coder EN801P-1024 Shaft Encoder involves the following steps:

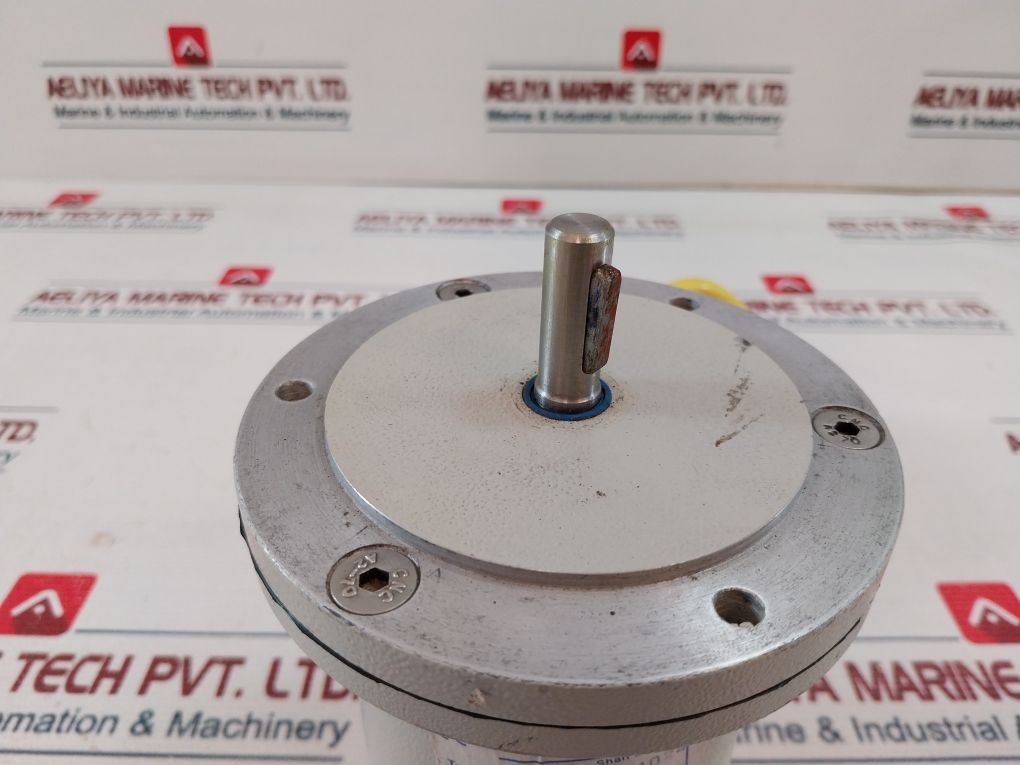

- Mounting: Securely attach the encoder to the shaft whose position or speed you want to monitor.

- Electrical Connection: Connect the encoder to the appropriate power source (10-30V DC) and to the control or monitoring system using the provided wiring.

- Configuration: Depending on your specific requirements, configure the encoder’s output signal, such as pulse count and signal format.

- Calibration: Calibrate the encoder to align its readings with the actual position or speed of the shaft.

Specifications/Features

- High-resolution shaft encoder for precise position and speed feedback

- Wide voltage supply range for compatibility with various systems

- Robust construction for durability in industrial environments

- Quadrature output for accurate monitoring

- Made in India, ensuring quality craftsmanship

Benefits

- Enhances precision and control in industrial processes

- Versatile and adaptable to diverse applications

- Reliable and durable construction for long-term use

Reviews

There are no reviews yet.