| Attribute | Value |

|---|---|

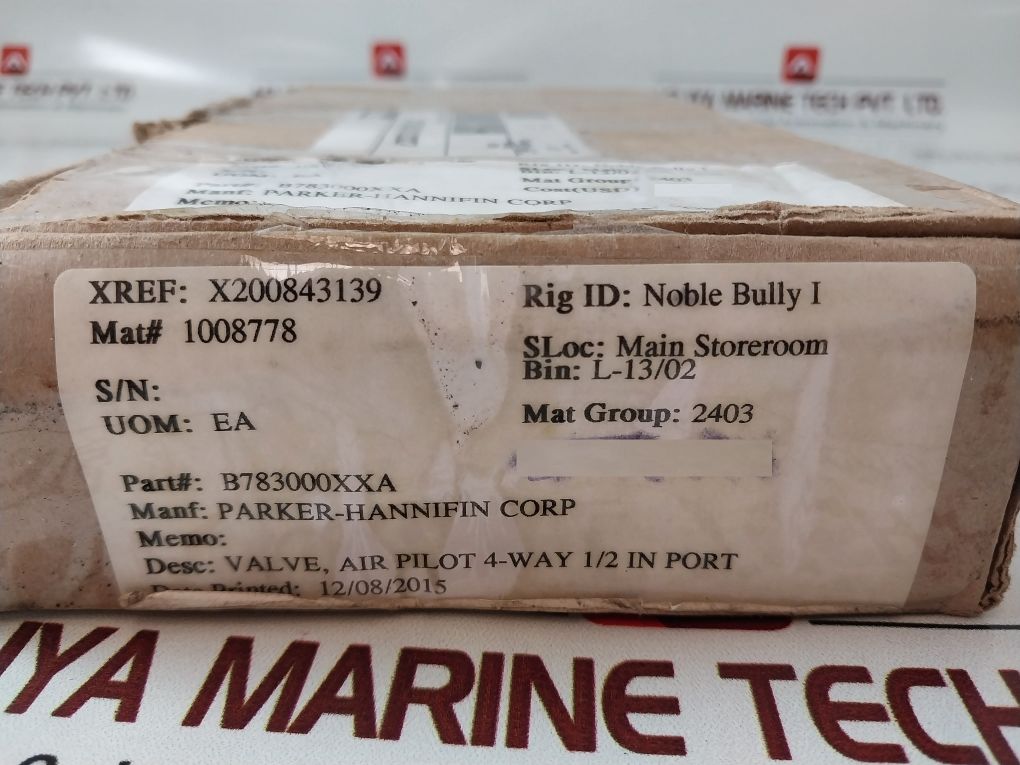

| Manufacturer | Parker-Hannifin Corp |

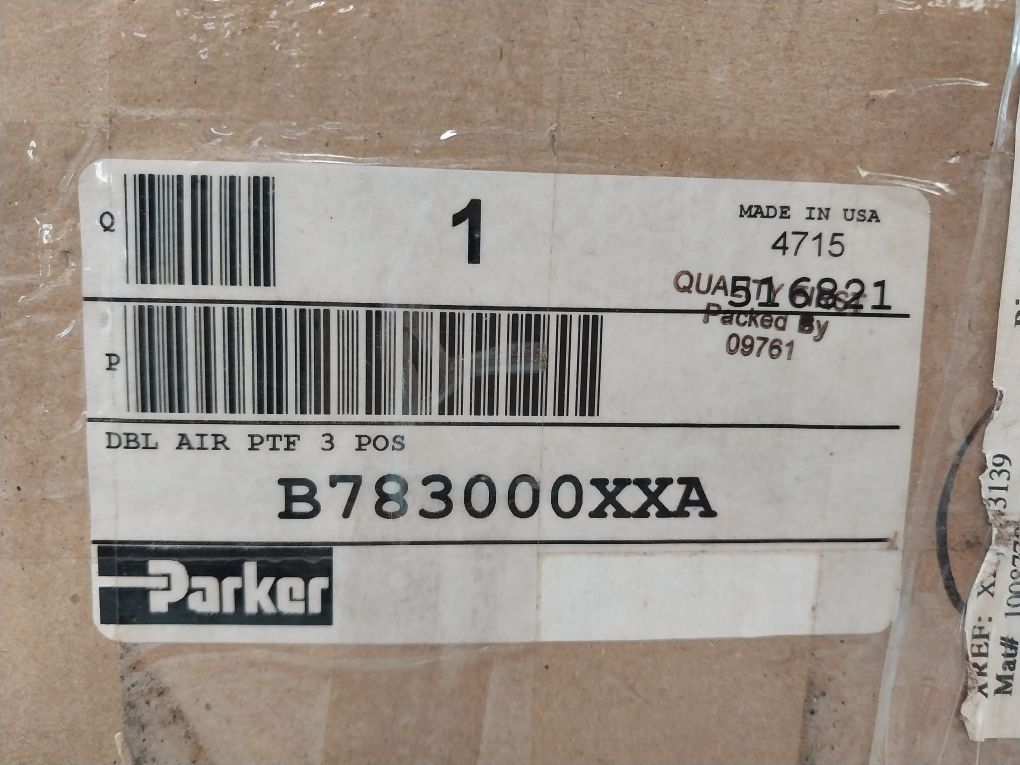

| Part Number | B783000xxa |

| Max Pressure | 145 Psi (1034 Kpa) |

| Model Number | 4715 |

| Cross Reference | X200843139 |

| Material Number | 1008778 |

| Description | Valve, Air Pilot 4-way 1/2 In Port |

| Type | Double Air PTF, 3 Position |

| Country of Origin | Made in USA |

| Weight | 1.370 Kg |

| Reference Number(s) | 58941 |

What is the Parker B783000xxa Valve?

The Parker B783000xxa is a 4-way air pilot-operated valve that is engineered for heavy-duty performance in harsh environments. Being one of the major components of Parker Hannifin’s valve solutions, this model is highly durable, responds quickly, and operates consistently. It’s normally employed to regulate the direction of air flow in pneumatic systems and plays a critical role in actuating cylinders and other pneumatic devices.

Key Features

Let’s dive deeper into what makes the B783000xxa an exceptional component in industrial applications:

1. 4-Way Configuration

This refers to the fact that the valve possesses four ports — two for work (actuator), one for pressure, and one for exhaust. This configuration is well-suited for reversing the motion of a double-acting cylinder.

2. Air Pilot Operation

Instead of being manually or electrically operated, this valve is operated by compressed air, which makes it possible for rapid response times and smooth operation.

3. Robust Construction

Parker B783000xxa is designed to operate under harsh conditions ranging from variable temperatures to high pressure. Its robust construction guarantees long working life even in constant use.

4. Lightweight and Compact

Though its robust performance, this valve is still lightweight and simple to install, providing a convenient solution for space-conscious applications.

5. Dependable Sealing and Flow Performance

With machined internals and top-quality sealing components, the B783000xxa provides very low leakage and excellent flow performance.

Applications

The Parker B783000xxa has a variety of industrial applications as a result of its flexibility and reliability. Its typical uses are:

- Automated equipment

- Material handling systems

- Packaging systems

- Textile equipment

- Robot arms

- Pneumatic press systems

In all these environments, the valve is central to regulating the airflow to actuators and managing the mechanical movement used in such operations.