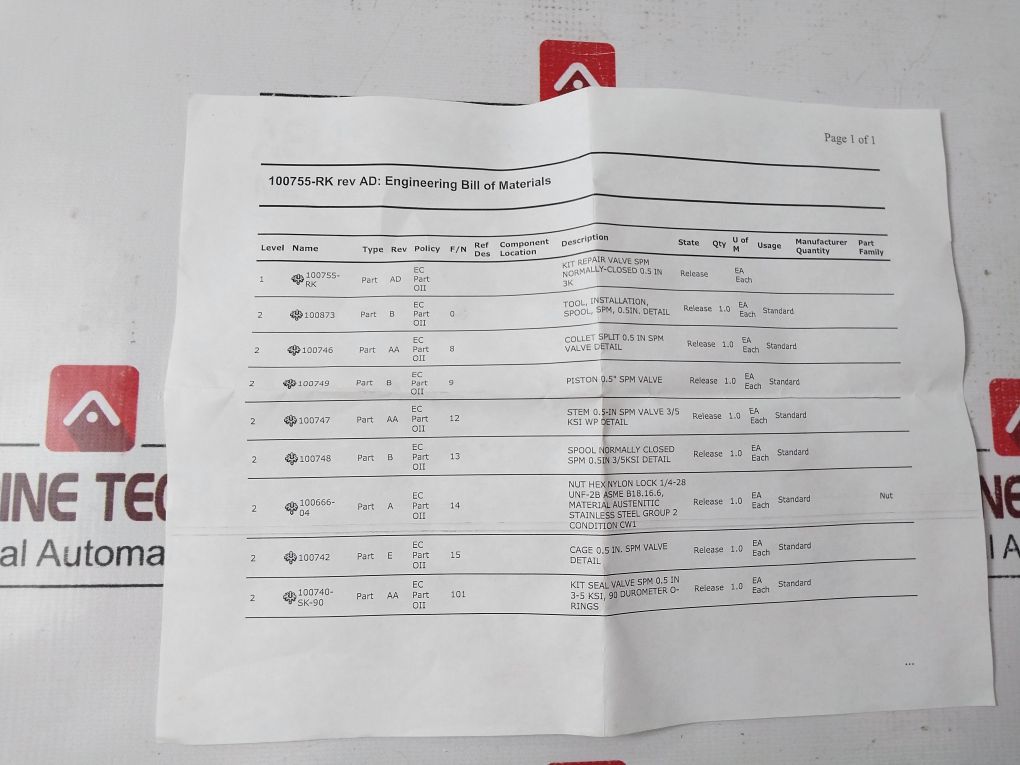

Oceaneering Parker Hannifin 100755-rk Valve Repair Kit

Manf: Oceaneering International Inc

Parker Hannifin Corp

P#: 100755-rk

Kit Repair Valve Spm Normally-closed 0.5 In 3k

Xref: X200284303

Mat# 449942

100746 Aa

Collet Split 0.5 In Spm Valve Detail

P/n: 0408391

O-ring Buna-n 2-130-n0552-90 Duro

P/n: 0397545

O-ring 2-129 Buna-n 90 Duro N0552

Pn: 100337-t0r205

T-seal Road 0.44 Id Nitrile W/pfte Back-up Rings

Rev: A

Mfg Pn: Tr005 N4115 B011

Description: Rod Nitrile 75a

7/16 X 11/16

Generic: Nitrile

Hardness 75a

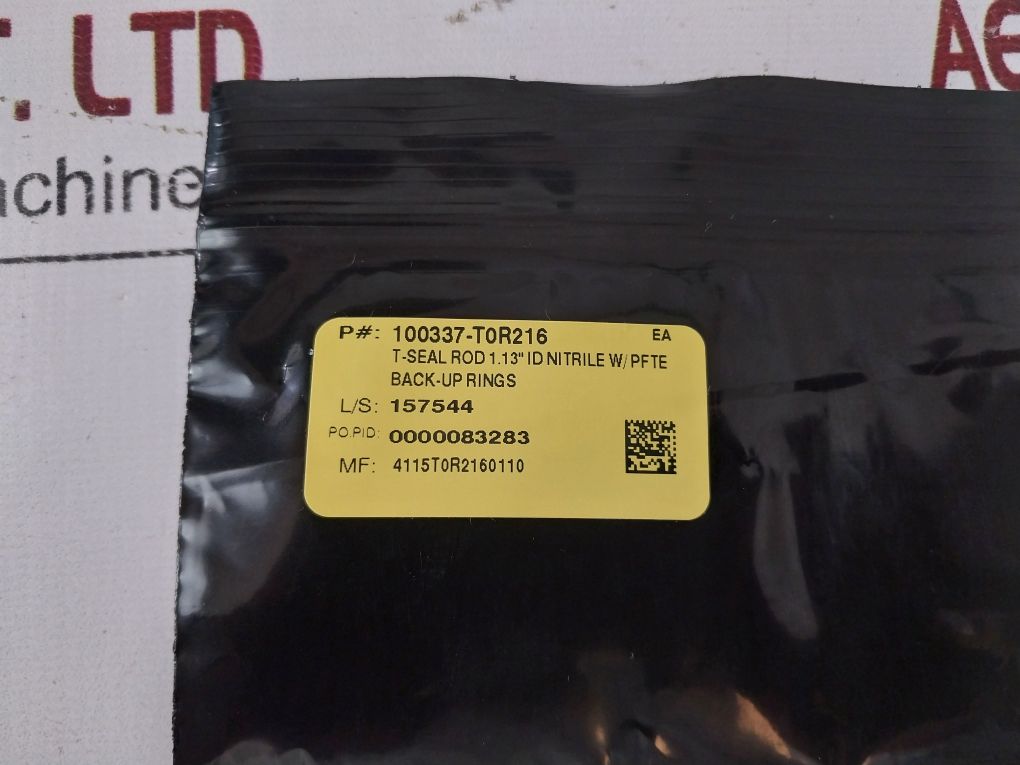

Pn: 100337-t0r216

Rev: A

Mfg Pn: Tr016 N4115 B011

Description: Rod Nitrile 75a

1 1/8 X 1 3/8

T-seal Rod 1.13” Id Nitrile W/pfte Back-up Rings

Mf: 4115t0r2160110

P#: 100337-t0r205

T-seal Rod .44” Id Nitrile W/ofte Back-up Rings

Mf: 4115t0r2050110

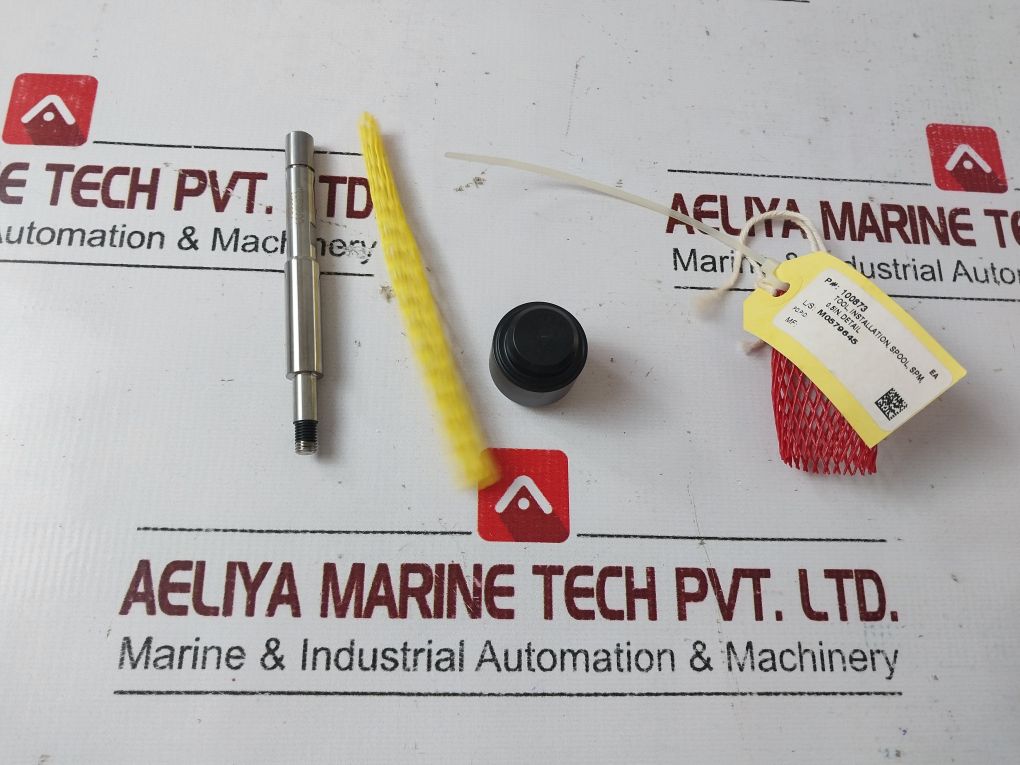

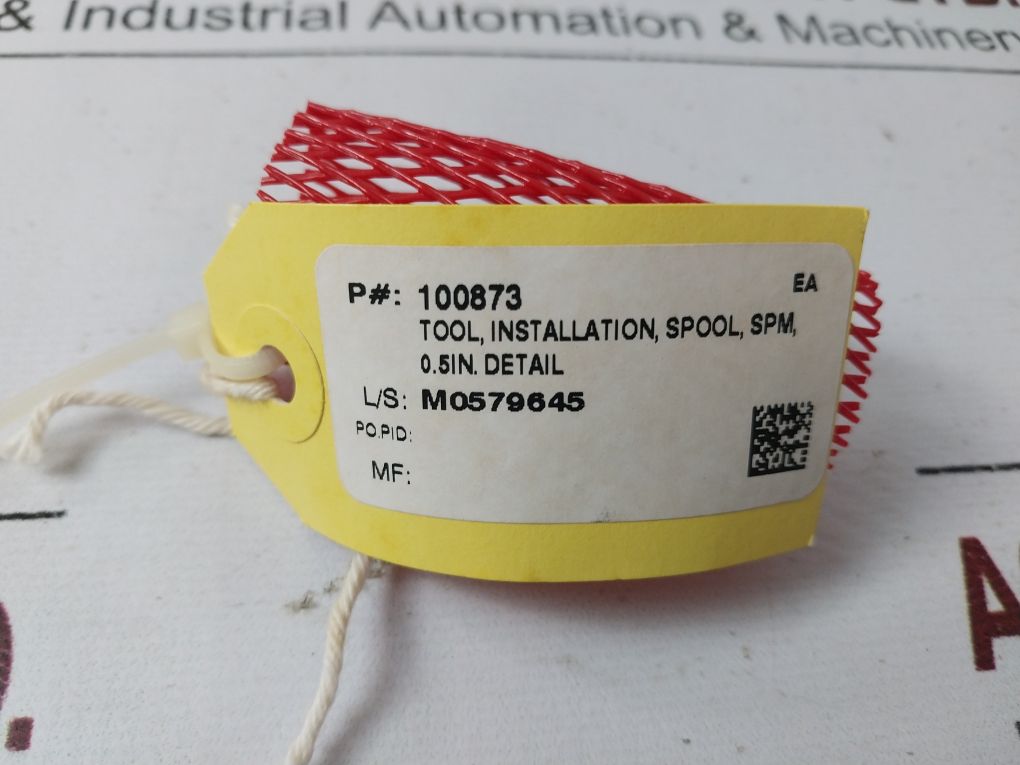

P/n: 100873-b

Ct# M0579645

P#: 100873

Tool, Installation, Spool, Spm, 0.5in Detail

100747 Aa

Stem 0.5-in Spm Valve 3/5 Ksi Wp Detail

N00864

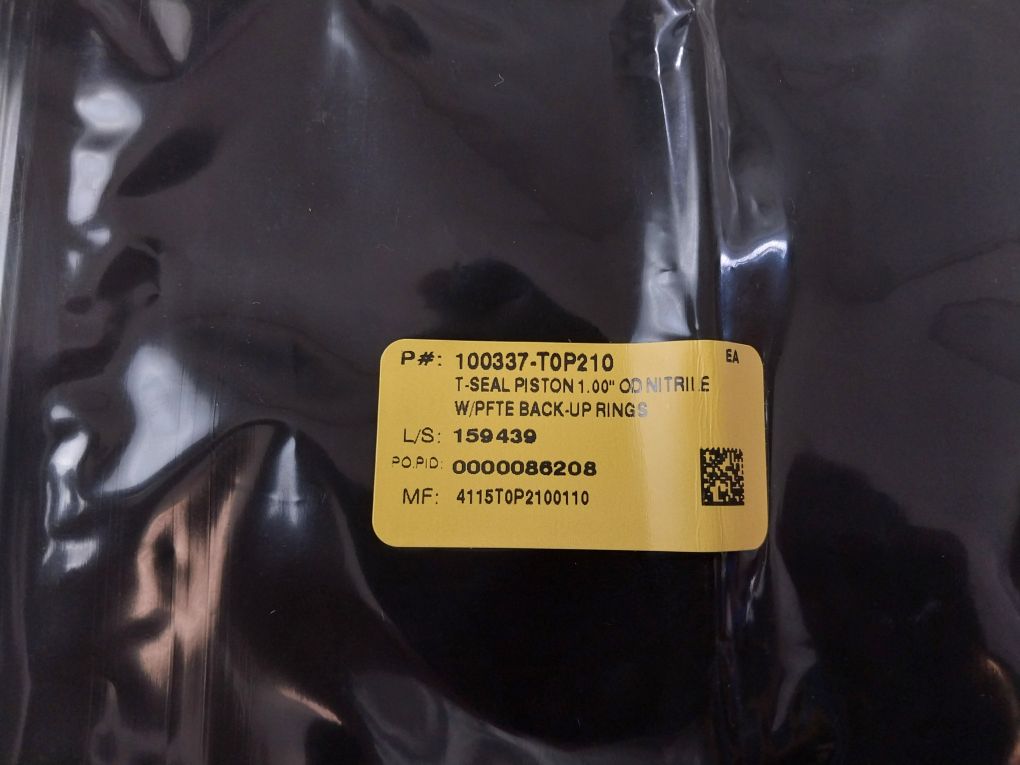

Pn: 100337-t0p210

Rev: A

Mfg Pn: Tp011 N4115 B011

Description: Piston Nitrile 75a

3/4 X 1

T-seal Piston 1.00” Od Nitrile W/pfte Back-up Rings

Mf: 4115t0p2100110

P#: 100741

Seat, Lower 0.5 Inch Spm Valve Detail

100743 B

P#: 100743

Rev B

Ht G20127

Seat Upper 0.5 In Spm Valve

P/n: 100740-sk-90

Kit Seal Valve Spm 0.5 In 3-5 Ksi, 90 Durometer O-rings

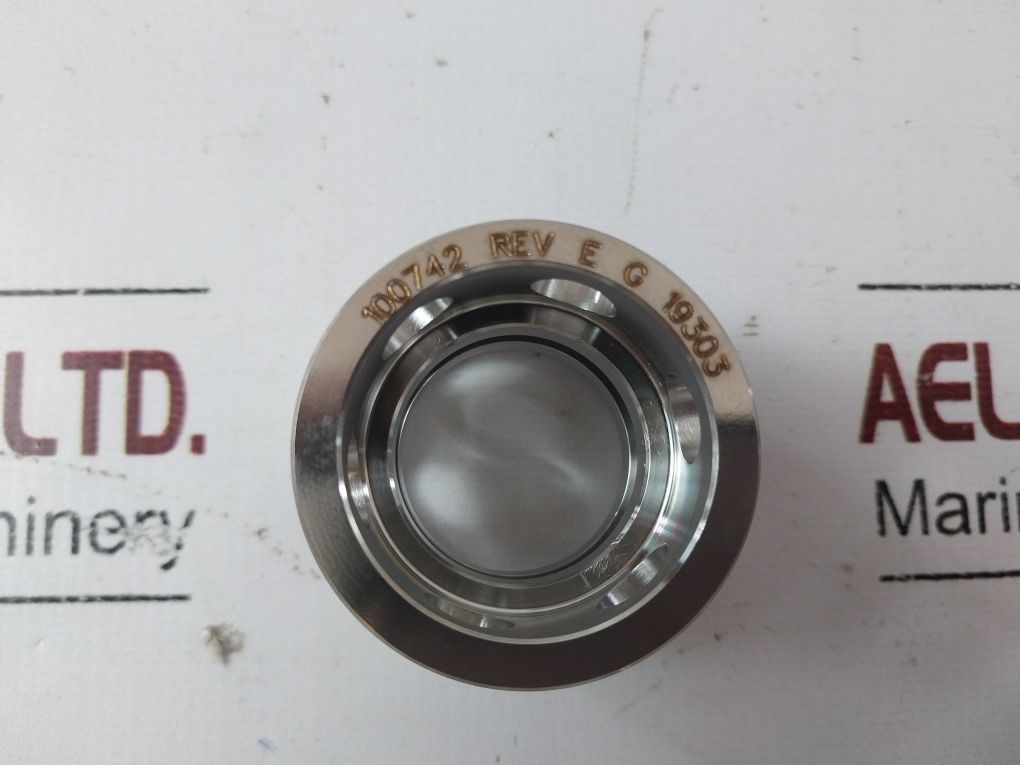

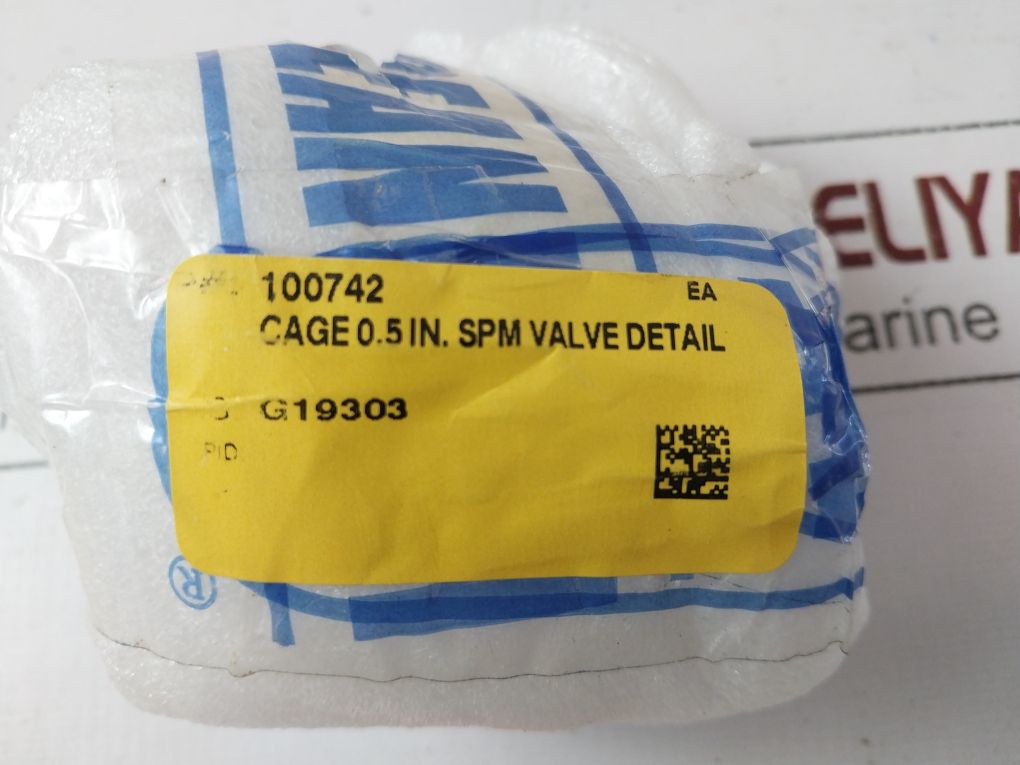

P#: 100742

Rev E

G 19303

Cage 0.5 In Spm Valve Detail

100749 B

W04607

P#: 100749

Piston 0.5” Spm Valve

P#: 100666-04

Nut Hex Nylon Lock 1/4-28 Unf-2b Asme B18.16.6. Material Austenitic Stainless Steel Group 2 Condition Cw1

P#: 100748

Spool Normally Closed Spm 0.5 In 3/5ksi Detail

Made In The Us

Weight : 750 Gm

Condition : New 2 Kit

Ref No : 63921

Understanding the Role of Valves in Industrial Systems

Prior to discussion on the Parker Hannifin 100755-RK Valve Repair Kit, one should first understand why valves are actually important in industrial operations. Valves are used to regulate, direct, or control fluids such as gases, liquids, and slurries flowing through a piping system. Valves are therefore pivotal in sectors like marine and oil and gas, and also for heavy machinery for ensuring the safety and efficiency of operation.

Valves also tend to degrade with time due to the relentless exposure they receive in harsh conditions like high pressure, corrosive materials, or fluctuating temperatures. Maintenance and proper system repair will only be guaranteed if action is taken promptly to avoid particular system failure, minimize down time, and have optimal operation. Here, the Oceaneering Parker Hannifin 100755-RK Valve Repair Kit is critical.

Key Features of Parker Hannifin 100755-RK Valve Repair Kit:

100755-RK is a valve repair kit from the famous Parker Hannifin Company, the global leader in fluid and motion control. This repair kit is a product used to regain the newness and functionality of a valve without replacing an entire valve. Some of the excellent benefits offered are as follows:

High-grade materials: The kit parts consist of machined high-grade material products designed for use in marine and offshore applications. The product has that been manufactured is corrosion resistant, withstanding wear and damage inflicted by the extreme operational environment.

Contained repair solution: In this kit, you are going to find everything that is required for valve repair – gaskets, seals, O-rings, springs, or any other important parts. This ensures that you get all the parts you need for efficient maintenance without having to look for them individually.

Exact fit: A kit like 100755-RK is manufactured to have an exact fit of specific Parker Hannifin valve models for a hassle-free and error-free repair process with optimal valve life cycle.

Easy to use: with simple instructions and well-structured parts, even less technically savvy operators can employ the set for repairs. This makes it easy to use by in-house maintenance teams.

Cost-effective Maintenance: The use of 100755-RK repair kit reduces the maintenance cost significantly as complete valve replacements would not be required. Besides, it lowers the downtime due to valve malfunction, an increasing efficiency of operation.

Benefits of Using Oceaneering Parker Hannifin 100755-RK Valve Repair Kit

Benefits in using a valve repair kit from such types as the Parker Hannifin 100755-RK can be seen in its application to industries employing complex piping and flow systems for various functions:

Extended Equipment Life: With this kit, the lifespan of your valves is guaranteed while replacing them less often; performance will not be maintained over time, though.

Least Downtime of Operations: Valves are often critical to an operation’s function. The fast repair process supported by this kit ensures minimum downtime and helps to avoid very costly production stoppages.

Better Safety: A valve system properly maintained ensures that fluids and gas are well controlled to prevent leaks or bursts or dangerous spills. This can be very sensitive in industries like oil and gas.

Environmental Protection: Also, with fewer leaks or spills caused by proper valve maintenance, risks to the environment also decrease. This package, therefore, makes the kit a responsible tool for companies interested in staying compliant in the regulations.

Applications of the 100755-RK Valve Repair Kit

The Parker Hannifin 100755-RK Valve Repair Kit is particularly useful in processes where the valves are subjected to harsh operating conditions. Among such industries include:

Marine and Offshore Platforms Fluid control valves in the marine sector’s ships, rigs, and other offshore installations play a critical role; however the 100755-RK kit helps to keep those valves in optimum operating condition, preventing costly breakdowns that could disrupt operations in remote locations.

The oil and gas industry absolutely depends on valves in controlling the flow of crude oil, natural gas, and others. In viscous fluid systems, they would generally face immense pressure as well as corrosive environments, so routine maintenance with quality repair kits would be necessary.

Valves for manufacturing plants provide an extensive field of liquid, gas, and chemical handling. The 100755-RK valve repair kit is designed to efficiently repair the mentioned components, thus minimizing downtime associated with production processes.