| Parameter | Details |

|---|---|

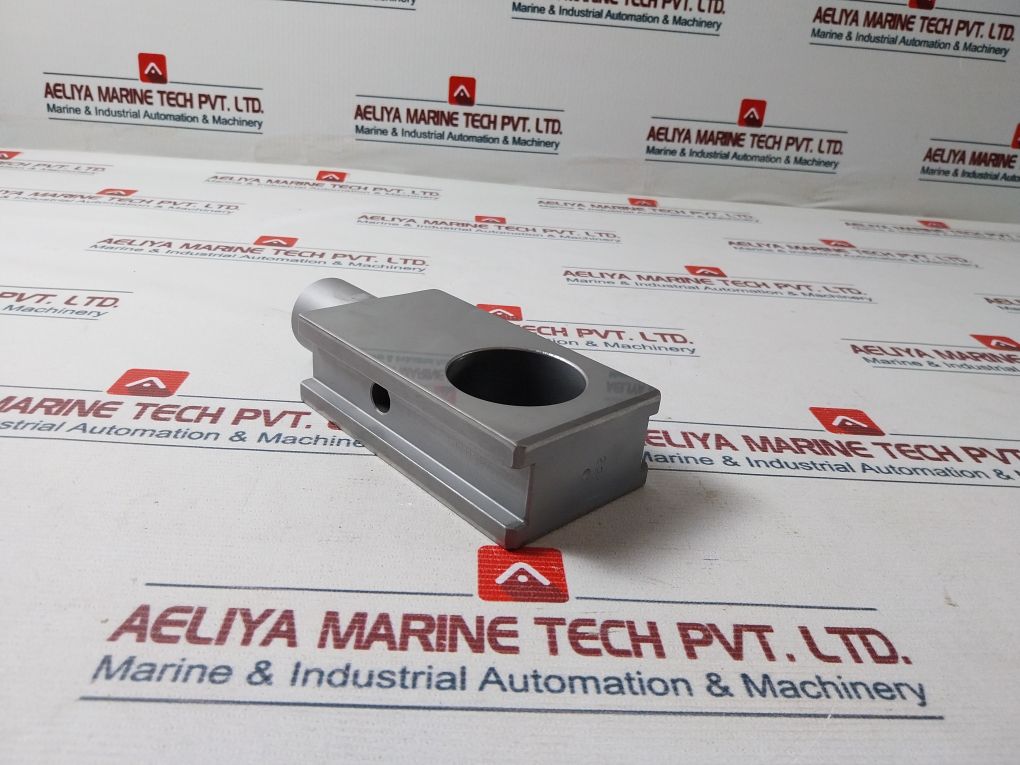

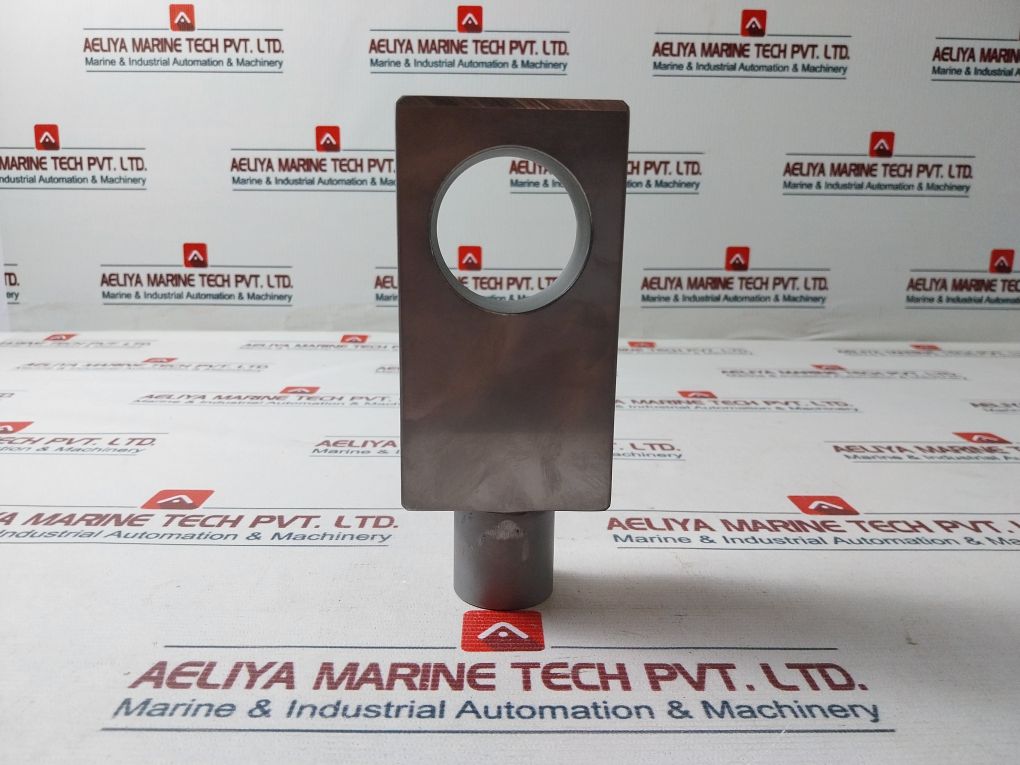

| Product Name | NOV 20363283 Gate Spare Man 2 1/16” 3/5/10/15K T3FC, 410SS Coat With TC |

| Manufacturer | NOV Energy |

| Brand | Manifold Valve Service, Inc. |

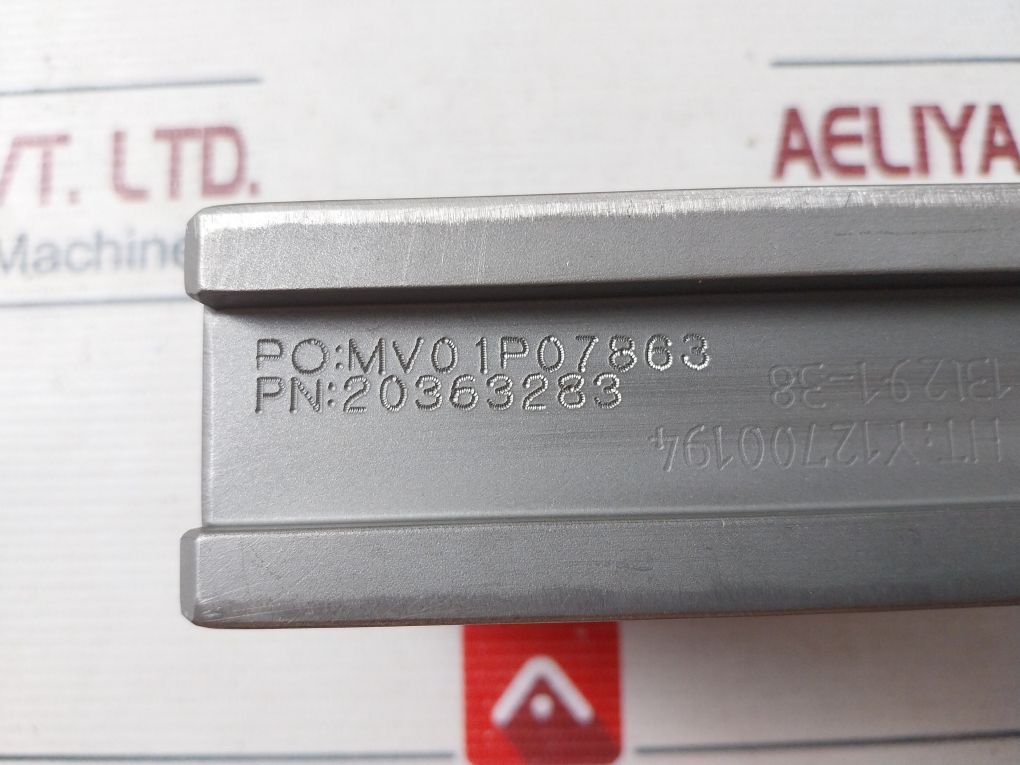

| Part Number | 20363283 |

| Reference Number | R18079 |

| Material | 410/SS |

| Height | Y12700194 |

| Additional Part Numbers | 13I291-38 S-19673-3 |

| Description | Gate Man 2 1/16” 3/5/10/15K T3FC, 410SS Coat With TC |

| Country of Origin | COO-USA |

| Weight | 2.320 Kg |

| Reference Number | 80101 |

Overview of NOV 20363283 Manifold Gate Valve

This manifold gate valve differs by high quality of construction, as well as the ability to provide long endurance even in intense situations. The robust body construction is of stainless steel 410 featuring a specialty coating with tungsten carbide (TC) used to provide an excellent protection from corrosion and erosion. Besides, its design with the potential facility of isolation along with flow control, it leads to improved performance in manifold systems.

Key Features and Benefits

1. High Durability:

The valve made use of a 410 stainless steel body that had a tungsten carbide coating which enabled it to work without cracking easily even in the most highly pressurized conditions. The coating significantly improved the valve’s resistance to corrosion and wear, thus suitable for operation in high demanding environments.

2. Pressure Management:

This gate valve has the capability of working under rigorous pressure conditions. It is designed for ratings up to 15,000 psi. Due to such pressure rating, this type of gate valve is suitable for operation in critical situations pertaining to drilling and oil and gas production.

3. Reliability for Flow Control and Isolation

This gate valve provides strict fluid flow control. When isolated, it delivers an effective seal, preventing potential leakage hazards and further ensuring higher system safety. This eliminates the chances for hazards to occur during operations.

4. Versatility in Application:

Since NOV 20363283 valve can adapt to the manifold system of other configurations, it can easily integrate to an existing manifold of a system. It accommodates an array of high-pressure applications in the processes of drilling and production besides refining processes.

5. Easy Maintenance and Lifecycle:

It is a valve with minimal maintenance, offering a long lifespan. This aspect makes it a low-cost solution where downtime and operating cost take center stage over time.

Technical Specifications

Some technical specifications of the NOV 20363283 gate valve include the following with such immense ability in its appearance:

Model Number: NOV 20363283

Type: Manifold Gate Valve

Material: 410 Stainless Steel (410SS)

Coating: Tungsten Carbide (TC)

Size: 2 1/16″

Pressure Ratings: 3K, 5K, 10K, 15K

Standards: Meets API and ISO specifications, which makes it competent for high-maintenance applications.

Applications of NOV 20363283 Manifold Gate Valve

The gate valve is quite versatile, thus making it appropriate for usage in different segments of oil and gas industries, and includes in major ones below:

Drilling and Extraction Operations:

In well control systems, this valve prevents any form of contamination, making sure system integrity is kept safe with this valve during the procedure of high-pressure drilling.

Production Manifolds:

It allows the operator to control flow rates effectively, hence optimizing fluid transfer between reservoirs and processing units.

Pipeline and Refining Operations:

The valve also finds application in pipeline isolation and refining operations. In these applications, the valve enhances system stability and safe management of fluids.

Wellhead Systems:

NOV 20363283 gate valves are handy in securing applications in wellhead applications as they allow for secure flow control, leakage, and the protection of wellhead equipment.

Why the NOV 20363283 Manifold Gate Valve?

The selection for a high pressure environment right gate valve is made with the requirement to ensure safe operations and achieve efficient functions. NOV 20363283 manifold gate valve contains a unique blend of durability, reliability, and versatility, making it the right choice for industries requiring performance under pressure. Its robust construction of TC-coated style is fully guaranteed for a long period and minimum maintenance in use thus minimizing service disruption at lower cost.

Reviews

There are no reviews yet.