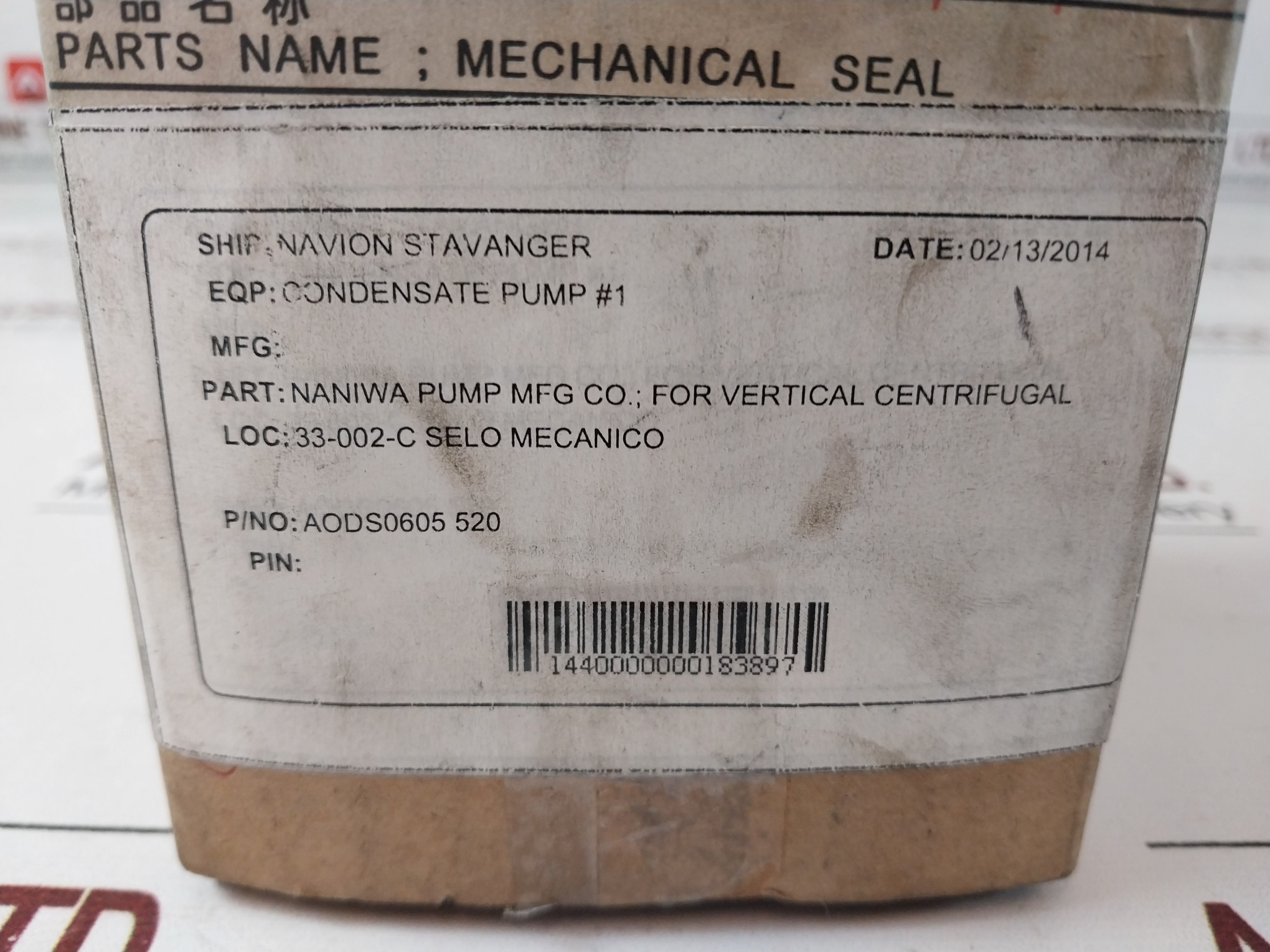

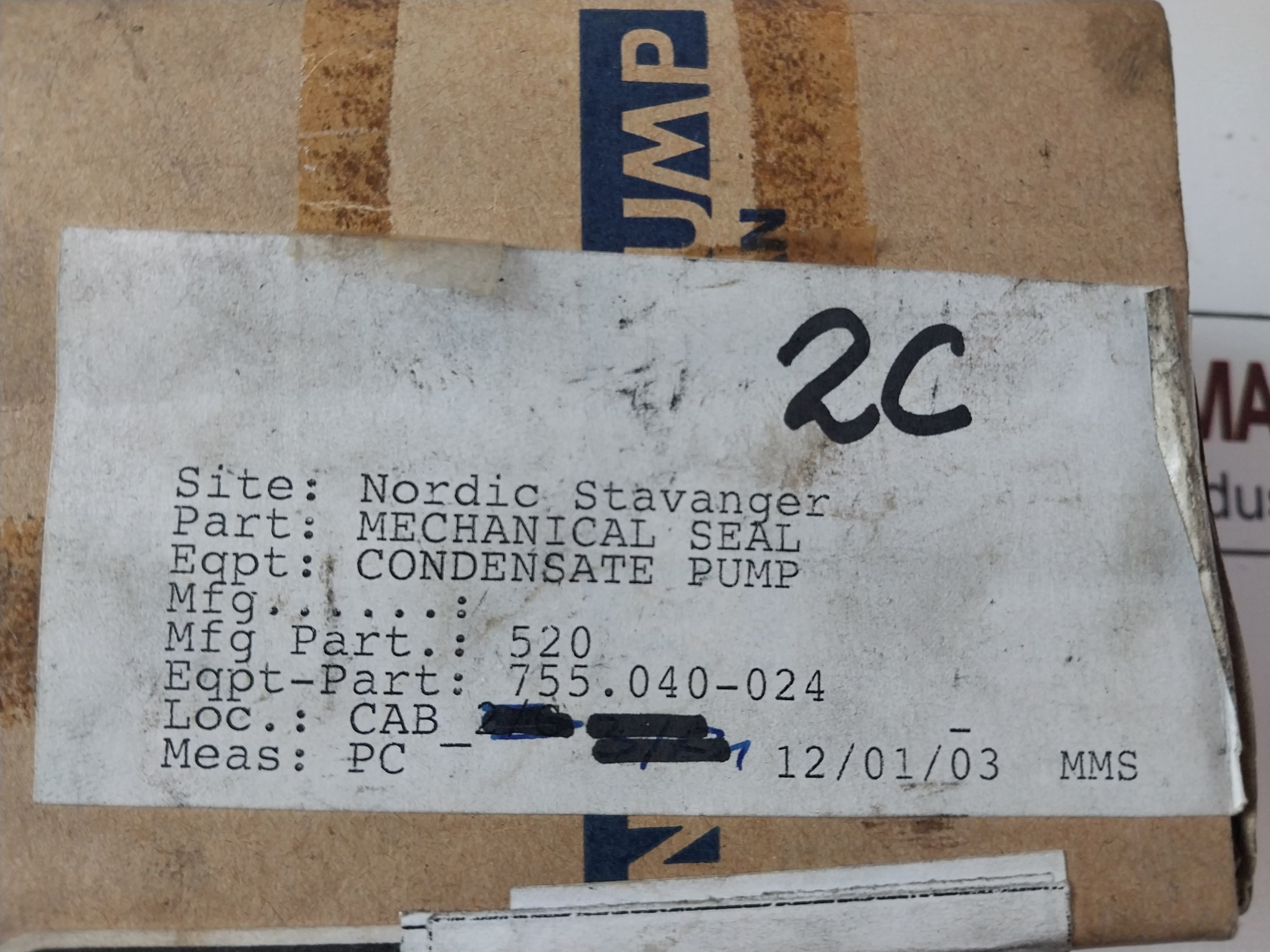

| Attribute | Value |

|---|---|

| Product Name | Naniwa 520 Mechanical Seal |

| Manufacturer | Naniwa Pump Mfg Co |

| Product Type | Vertical Centrifugal |

| Part Number | Aods0605 520 |

| PIN | 1440000000183897 |

| Part | Mechanical Seal |

| Equipment | Condensate Pump |

| MFG Part | 520 |

| Equipment Part | 755.040.024 |

| Weight | 700 Gm |

| Reference Number | 64834 |

What is Naniwa 520 Mechanical Seal?

The Naniwa 520 is a heavy-duty mechanical seal for protecting rotating machinery like pumps, compressors, and mixers. The Naniwa Pump Manufacturing Co., Ltd., a well-established name in marine and industrial pumping solutions, produces this seal. The seal is renowned for its longevity and leak-free operation under harsh conditions.

Important Characteristics of the Naniwa 520 Mechanical Seal

Long Lasting Materials

Made from corrosion-resistant materials such as stainless steel, carbon, and silicon carbide, the seal is designed to last under aggressive chemicals and extreme temperatures.

Precision Fit

Designed with close tolerances for a firm fit and minimal wear, minimizing the risk of leakage with age.

Compact Design

Compact design that fits well in tight spaces.

Balanced Seal Configuration

Prevents uneven pressure distribution and increases seal life, particularly in high-pressure applications.

Replaceable Seal Faces

Low-cost design with readily replaceable parts, enabling rapid maintenance.

Uses of the Naniwa 520 Seal

Naniwa 520 Mechanical Seal is versatile and can be applied to a broad range of industries, such as:

Marine Industry

Widely utilized in marine pump sets on ships and offshore structures for cooling, bilge, ballast, and firefighting systems.

Oil & Gas

Facilitates crude oil transfer, chemical blending, and high-temperature fluid handling operations.

Water Treatment Plants

Assists in leak-proof sealing in pumps used for chemical dosing, sludge transfer, and filtration processes.

Food & Beverage Industry

Provides hygienic sealing in food-grade pumps where cleanliness is also essential and leakage should be avoided.

Power Plants & Manufacturing Units

Assures consistent performance in coolant pumps, hydraulic systems, and chemical circulation.

Advantages Over Traditional Seals

Increased Lifespan: Designed to last even with extreme wear conditions.

Lower Downtime: Fast installation and minimal maintenance lead to fewer operation interruptions.

Energy Efficient: Its exacting construction avoids friction losses and lowers power use.

Cost Savings: Increased seal life and exchangeable components translate into lower overall cost of ownership.