| Attribute | Value |

|---|---|

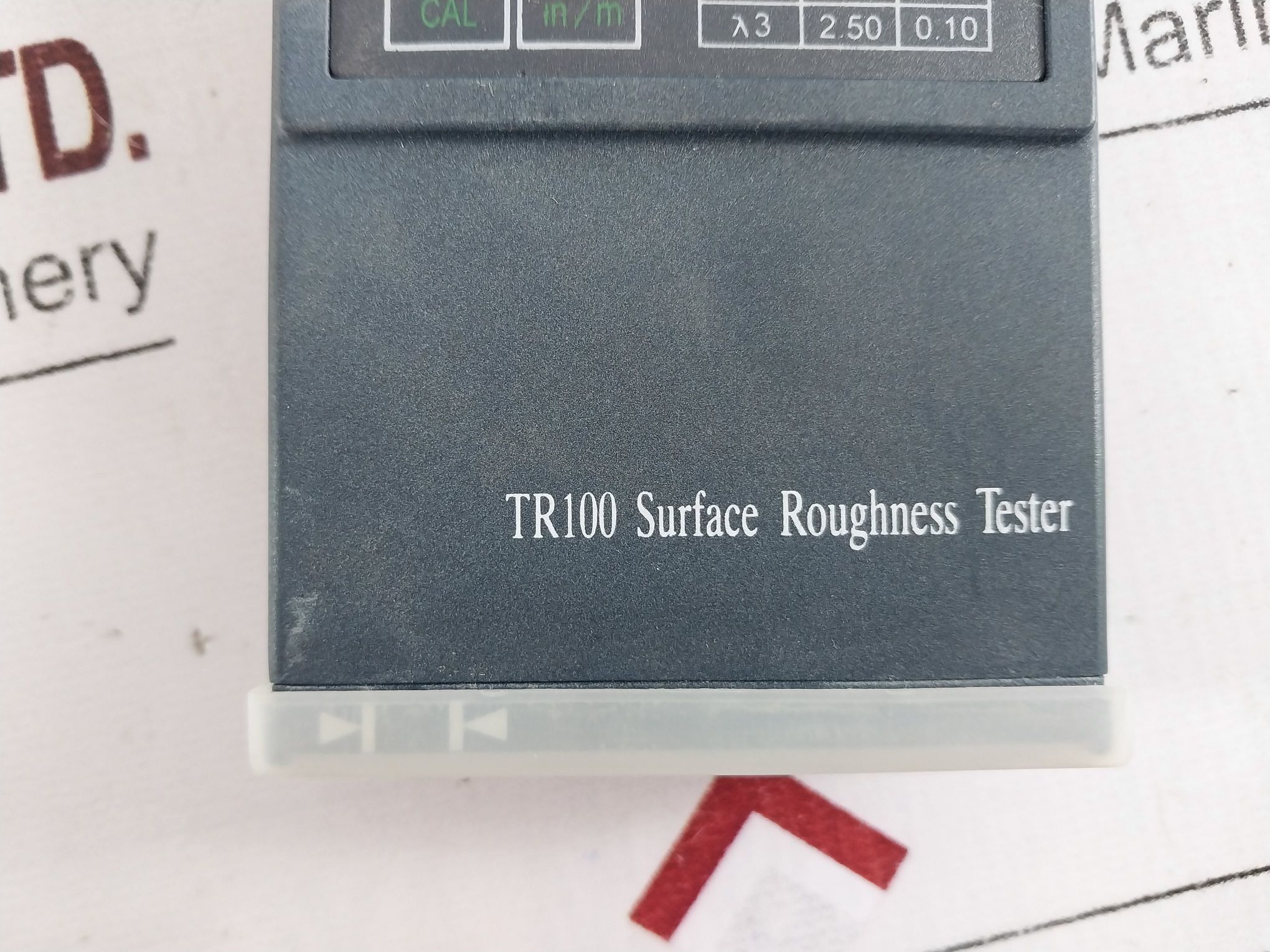

| Brand | Moore & Wright |

| Model | Tr100 |

| Type | Surface Roughness Tester |

| Series | Sur150d |

| Part Number | 27306-111 |

| Weight | 200 Gm |

| Ref No (SP) | 67271 |

Overview of Moore & Wright SUR150D

SUR150D is a portable surface roughness tester used to measure roughness on different surfaces fast, simply, and accurately. It comes with several roughness parameters, has an easy-to-use interface, and can be used both in-site and in laboratories. Equipped with a clear display, optional built-in printer, as well as data output, it has become a favorite among engineers, quality inspectors, and machinists.

Key Features

1. Large Measuring Range

SUR150D features a wide measuring range for Ra, Rz, and other significant surface parameters, which allows it to be flexible with various types of materials and levels of finish.

2. Easy-to-Read Digital Display

It features a large LCD display with backlight, making readings easily readable even in dimly lit workplaces.

3. Several Roughness Parameters

The tester accommodates multiple surface roughness standards, such as Ra, Rz, Rt, Rq, and others – offering flexibility based on industry demand.

4. Easy-to-Use Operation

With simplicity at its core, it boasts a simple user interface that takes minimal training time, enabling operators to start testing within minutes.

5. Battery Powered with Recharge Feature

The rechargeable battery built in guarantees long runtime, perfect for mobile applications throughout workshop floors or field checks.

6. Storage and Output of Data

With USB output and data logging, you can export and store measurements for recording or analysis, making quality control processes easier.

7. Robust Construction

Moore & Wright’s SUR150D has been built with durability in mind – contained within a strong casing that shields it from slight bumps, dust, and general workshop use.

Applications of Moore & Wright SUR150D

The SUR150D is extensively applied in industries where surface finish affects functionality or appearance, such as:

Precision Machining: Verifies the surface finish conforms to design tolerances and performance requirements.

Automotive Manufacturing: Inspects wear surfaces, sealing surfaces, and contact surfaces.

Metal Fabrication: Tests finish after grinding, turning, or milling operations.

Quality Inspection Labs: Applied as part of quality control to ensure production consistency.

Tool & Die Industry: Essential for determining finished molds and die surfaces.

Aerospace: Inspects parts where aerodynamics and friction are affected by surface roughness.

Why Select Moore & Wright SUR150D?

Selecting the SUR150D is an investment in a respected product from a heritage company in precision tools. Moore & Wright has been providing to the engineering world for more than a century, and their dedication to excellence shines through in every aspect of this tool. The SUR150D is not a tester alone – it’s a productivity driver, a quality check helper, and a reliability ally.

It minimizes rework, enables improved decision-making on the shop floor, and ultimately allows you to continue manufacturing at high standards. If you’re a small workshop or a large-scale production facility, this tool provides measurable value.

Reviews

There are no reviews yet.