| Attribute | Value |

|---|---|

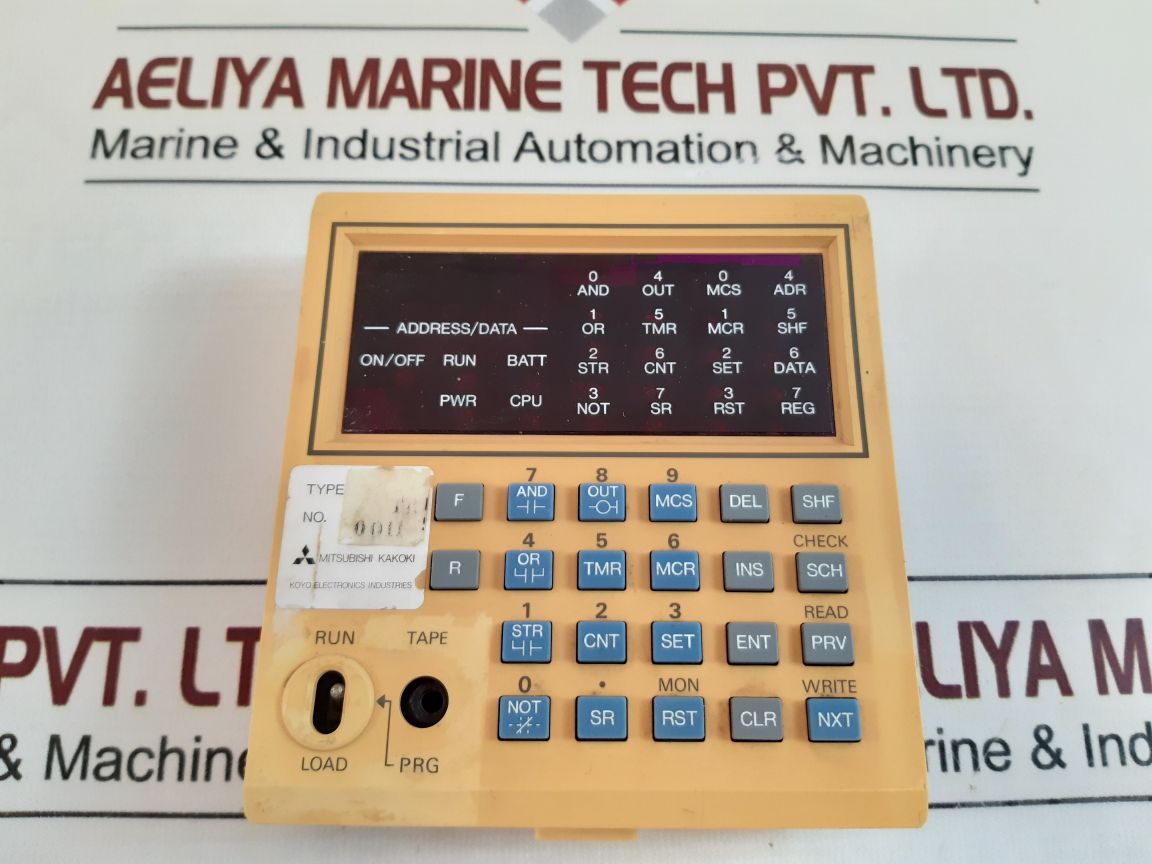

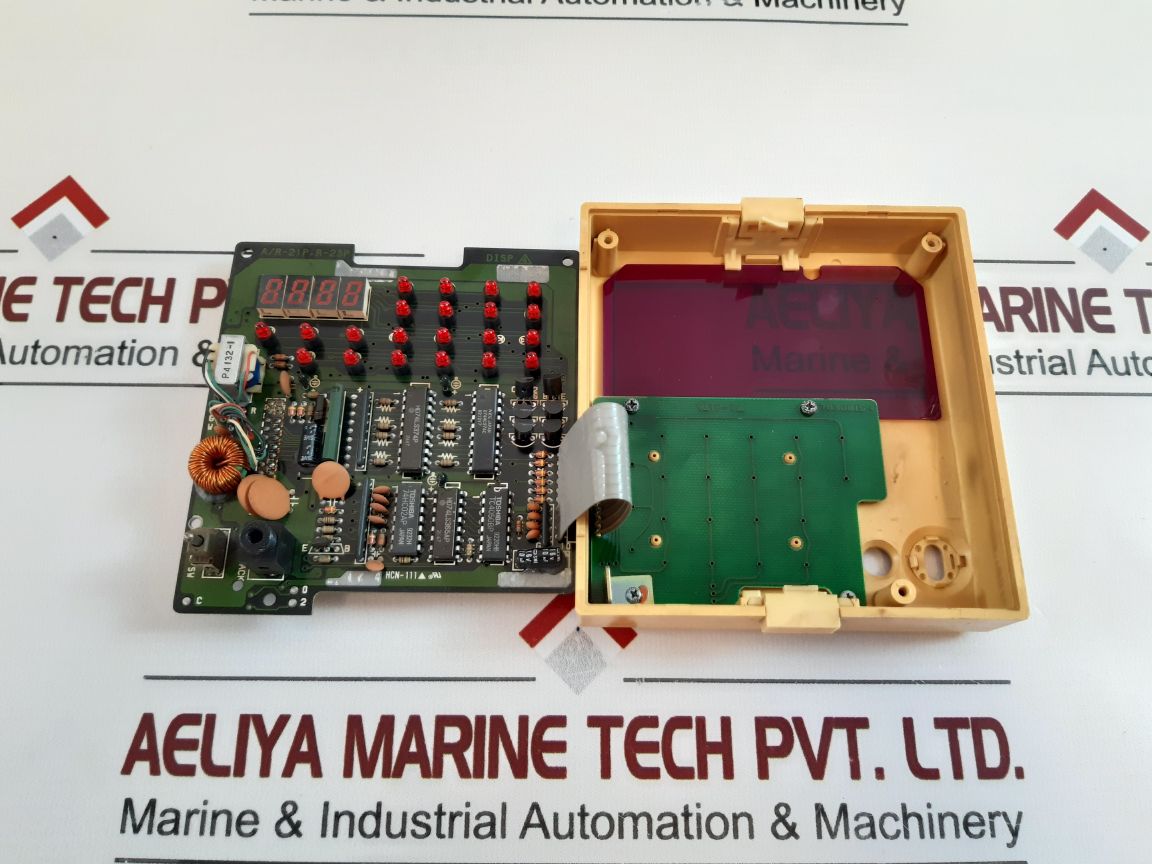

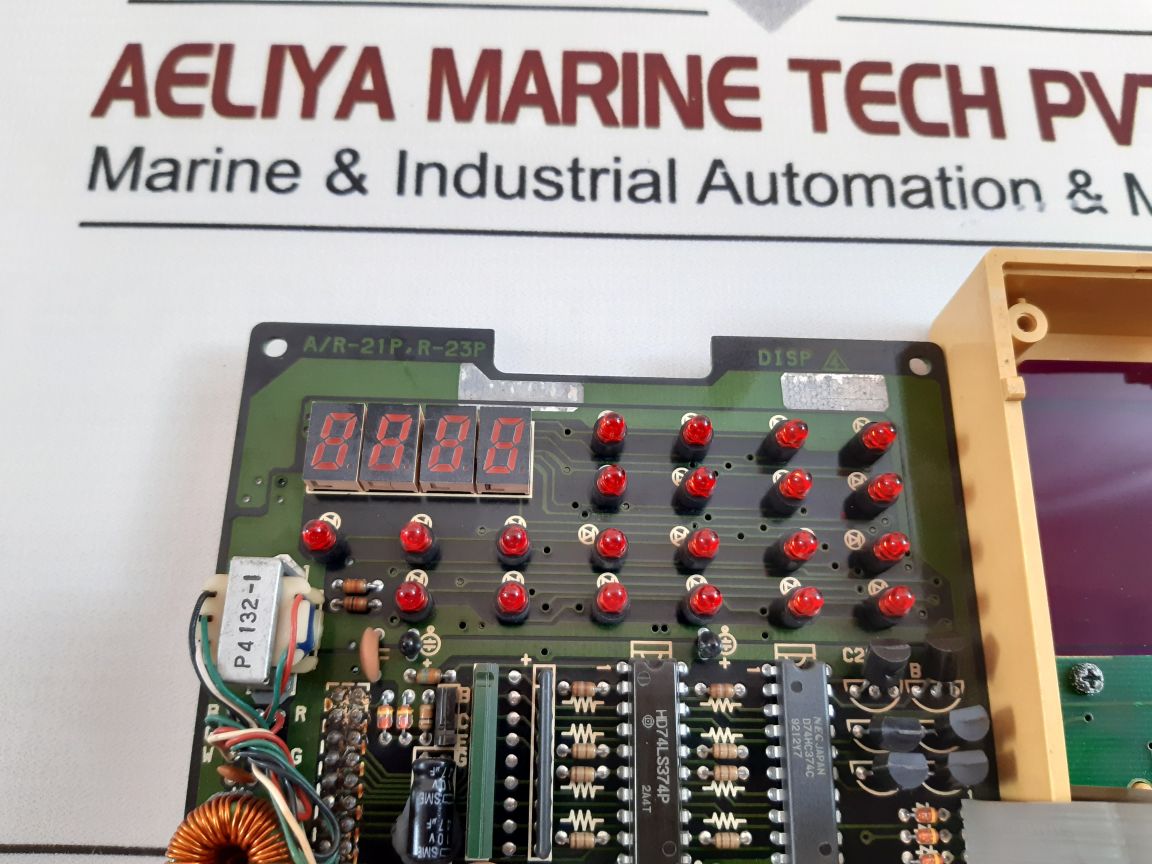

| Product | MITSUBISHI KAKOKI KOYO ELECTRONICS A/R-21P, R-23P PROGRAMMABLE CONTROLLER |

| Brand / Maker | MITSUBISHI KAKOKI; KOYO ELECTRONICS INDUSTRIES |

| Model / Series | A/R-21P, R-23P |

| Additional IDs | 921014621; 7821314-4; HCN-111; 7830815-1 |

| Weight | 200 gm |

| Condition | Used |

| Quantity | 3 pcs |

| Reference No. | 51680 |

What is the Mitsubishi KAKOKI KOYO ELECTRONICS A/R-21P, R-23P Programmable Controller?

The Mitsubishi KAKOKI KOYO ELECTRONICS A/R-21P, R-23P Programmable Controller is a compact and highly efficient automation device designed to manage, control, and monitor complex industrial operations with precision. Developed by Mitsubishi KAKOKI in collaboration with KOYO Electronics, this controller combines Japanese engineering excellence and advanced digital logic technology to ensure smooth, uninterrupted control of automated systems.

Programmable controllers like the A/R-21P and R-23P serve as the brain of industrial machinery, allowing engineers to program custom logic sequences, automate workflows, and enhance system efficiency across multiple applications. Its modular structure and reliability make it ideal for both marine and industrial environments.

Key Features of Mitsubishi KAKOKI KOYO A/R-21P, R-23P

Advanced Programmable Logic Control (PLC):

Built with a high-speed CPU to handle multiple I/O operations simultaneously, ensuring precise timing and coordination in automation processes.

Modular and Expandable Design:

Supports expansion modules for additional I/O points, communication ports, or specialized control functions—offering flexibility for customized automation needs.

Durable Industrial Build:

Designed with high-grade components that withstand vibration, temperature changes, and humidity, making it suitable for marine, manufacturing, and process industries.

Reliable Data Communication:

Offers strong data connectivity between various sensors, drives, and systems using standard industrial communication protocols.

User-Friendly Programming Interface:

Compatible with Mitsubishi and KOYO software environments, providing intuitive setup, debugging, and maintenance processes.

Energy-Efficient Operation:

Reduces power consumption through intelligent control algorithms—ensuring long-term operational efficiency.

Safety and Protection Features:

Includes built-in fail-safe and overload protection mechanisms that prevent equipment damage during voltage fluctuations or unexpected faults.

Applications of the A/R-21P and R-23P Programmable Controller

The versatility of the Mitsubishi KAKOKI KOYO A/R-21P and R-23P models allows them to be used in a wide range of industrial automation applications, including:

Marine Automation:

Ideal for controlling pumps, valves, and ship engine monitoring systems where precision and reliability are vital.

Manufacturing Plants:

Automates assembly lines, conveyor systems, and robotic operations with consistent accuracy.

Process Control Systems:

Used in oil, gas, and chemical industries for monitoring flow rates, temperature, and pressure control.

Power Generation Units:

Manages synchronization, load distribution, and protection mechanisms in energy systems.

Water Treatment and HVAC Systems:

Controls filtration, temperature, and air regulation efficiently to maintain consistent performance.

Material Handling Systems:

Provides smooth operation of cranes, lifts, and conveyor logistics within factory automation.

Why Choose Mitsubishi KAKOKI KOYO A/R-21P, R-23P Controller?

1. Trusted Japanese Engineering

Mitsubishi and KOYO are globally recognized for producing reliable and long-lasting automation components. Their joint design ensures high standards of manufacturing quality and technical performance.

2. Compact Yet Powerful

Despite its compact footprint, this controller delivers fast processing speeds and efficient I/O handling, making it suitable for both small and large automation setups.

3. Seamless Integration

Easily integrates with other Mitsubishi and KOYO PLCs, HMIs, drives, and sensors, providing a complete system solution without compatibility issues.

4. High Reliability in Harsh Environments

Its robust build allows it to perform reliably under marine conditions such as high humidity, temperature fluctuations, and vibration.

5. Cost-Effective Automation

Provides a high return on investment by reducing downtime, increasing production speed, and minimizing energy waste.

6. Simplified Maintenance and Upgrades

Modular structure allows easy replacement or upgrading of individual parts without changing the entire system—saving time and operational cost.