| Attribute | Value |

|---|---|

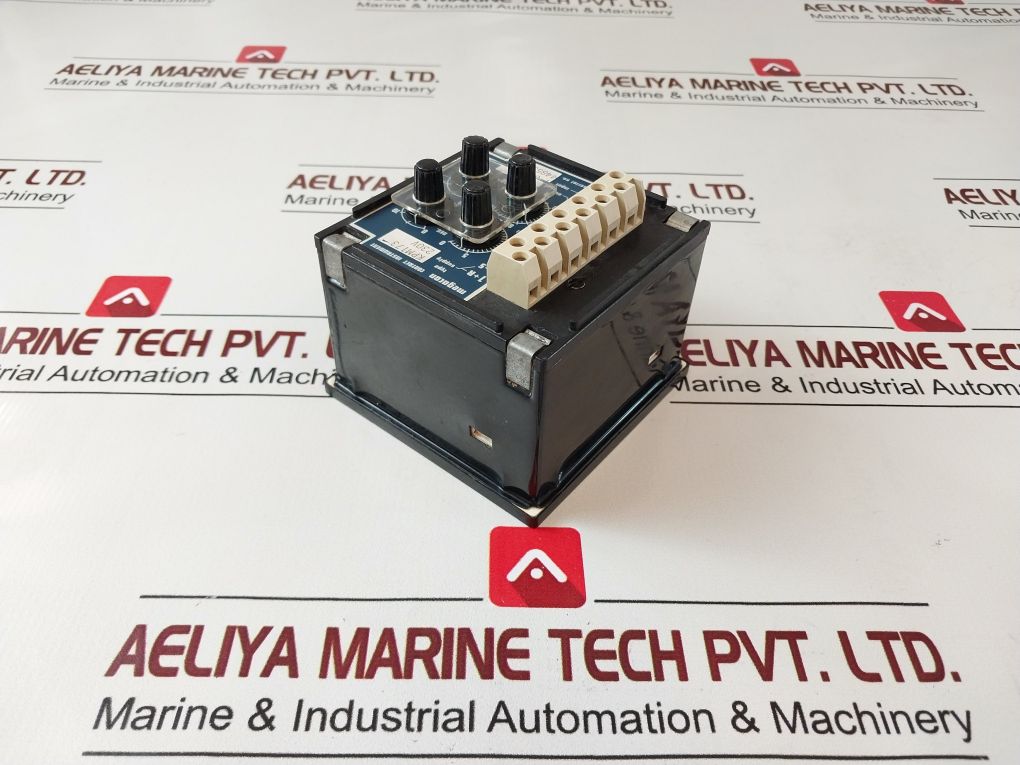

| Product Name | Megacon KPM173 Bi-directional AC Power Guard |

| Brand | Megacon |

| Category | Contact Instrument |

| Type | KPM173 |

| Function | Bi-directional AC Power Guard |

| Measurement Range | 0.12 to 1.2 MW |

| Supply Voltage | 230V |

| Input | 1-0-10mA |

| Weight | 500 gm |

| Condition | Used – 1 Pcs |

| Reference Number | 59112 |

Characteristics of Megacon KPM173

Bi-Directional Measurement: It has the ability to measure power flow in both directions, which makes it suitable for regenerative loads or multiple-source systems.

Accurate Measurement: With a Class 1.5 accuracy specification, it is a reliable and accurate monitor.

Large Input Range: It has been designed for input signals in the range 1-0-10 mA, which supports compatibility with several current transformers.

Versatile Supply Voltage: Runs on 200–240V AC, 50/60Hz supply voltage, which accommodates most industrial installations.

Strong Build: Packaged in a rugged housing with a small footprint, it can withstand tough environments.

Lightweight Construction: It weighs around 480 grams, making it simple to integrate into panels.

Uses of Megacon KPM173

The KPM173 finds extensive use across various industries owing to its versatile features:

1. Marine and Offshore

Provides safe power flow management in ships and offshore platforms where synchronization of generators and load sharing is essential.

2. Power Plants

Utilized in generator and turbine control boards to monitor in real-time and protect against overloading or reversing power conditions.

3. Industrial Automation

Assists in controlling energy flows within production lines, especially regenerative braking or multi-source power lines.

4. Renewable Energy Systems

Suitable for solar and wind setups with power flow in opposite directions owing to storage and interaction with the power grid.

Why Use Megacon KPM173?

What sets Megacon KPM173 apart is its precision in detecting directional power and responding quickly to safeguard electrical systems. It minimizes downtime, prevents equipment damage, and provides safety for both systems and people. Its ease of installation and compatibility with common control systems make it a first choice among engineers and technicians globally.