| Attribute | Value |

|---|---|

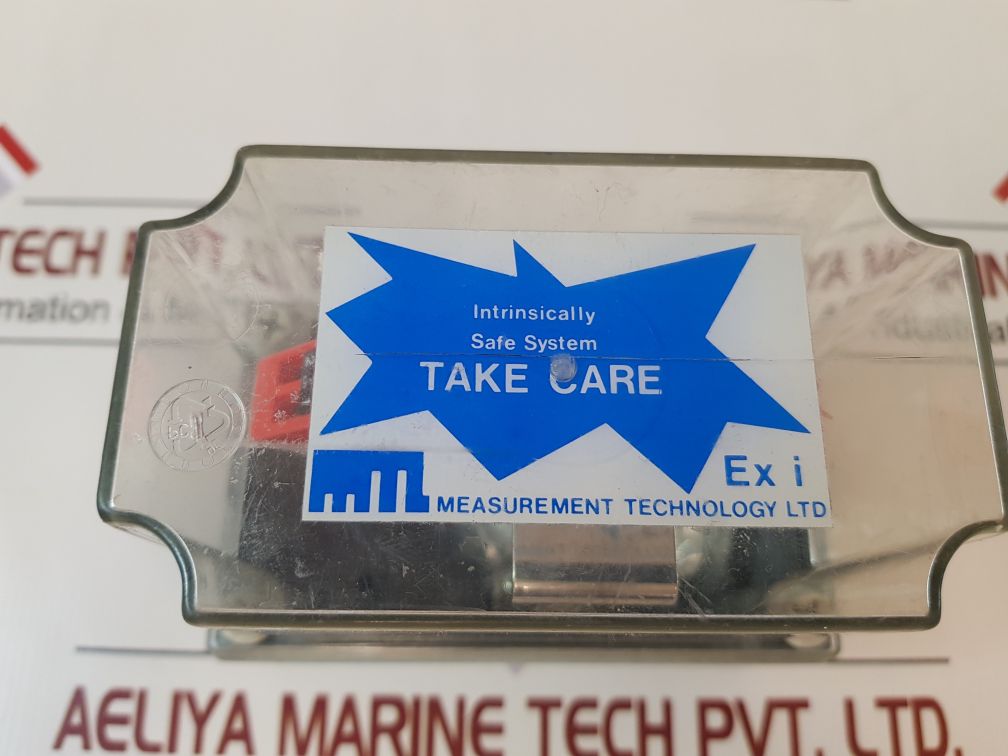

| Brand | MEASUREMENT TECHNOLOGY LTD. |

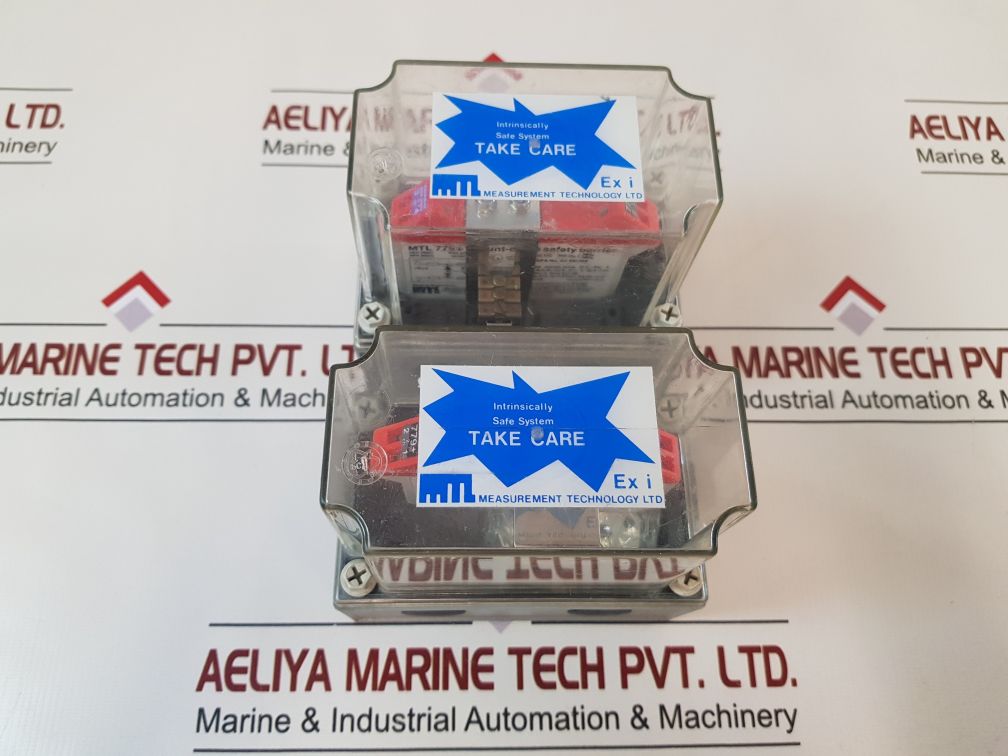

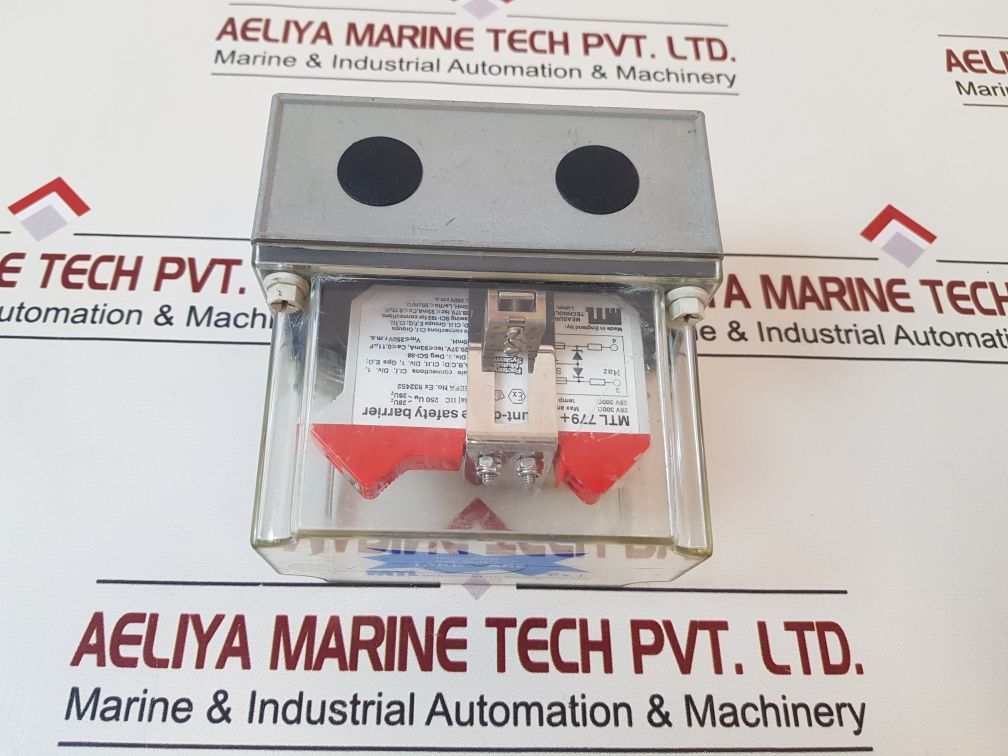

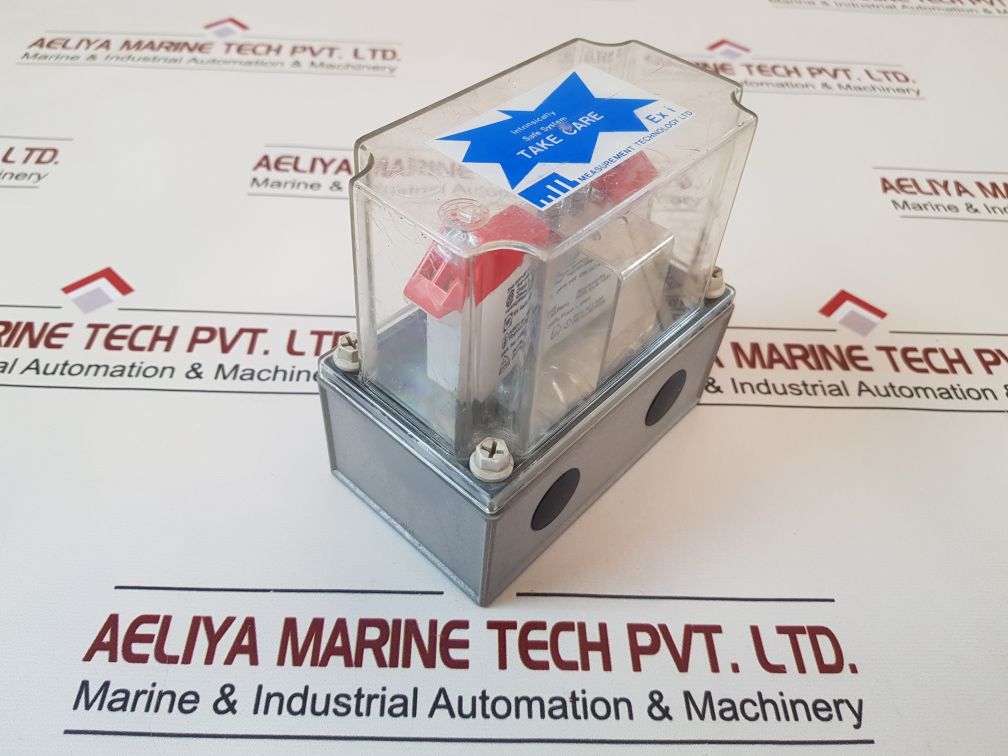

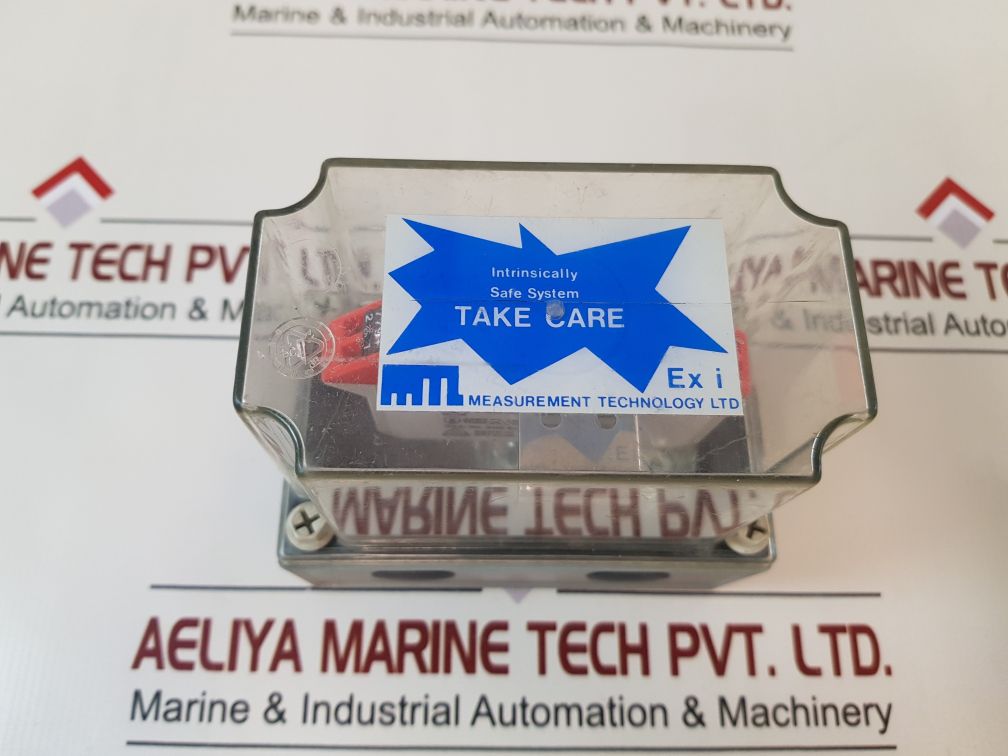

| Model | MTL 779+ |

| Description | SHUNT-DIODE SAFETY BARRIER |

| Specifications | 28V 300Ω MAX AMB TEMP 60°C |

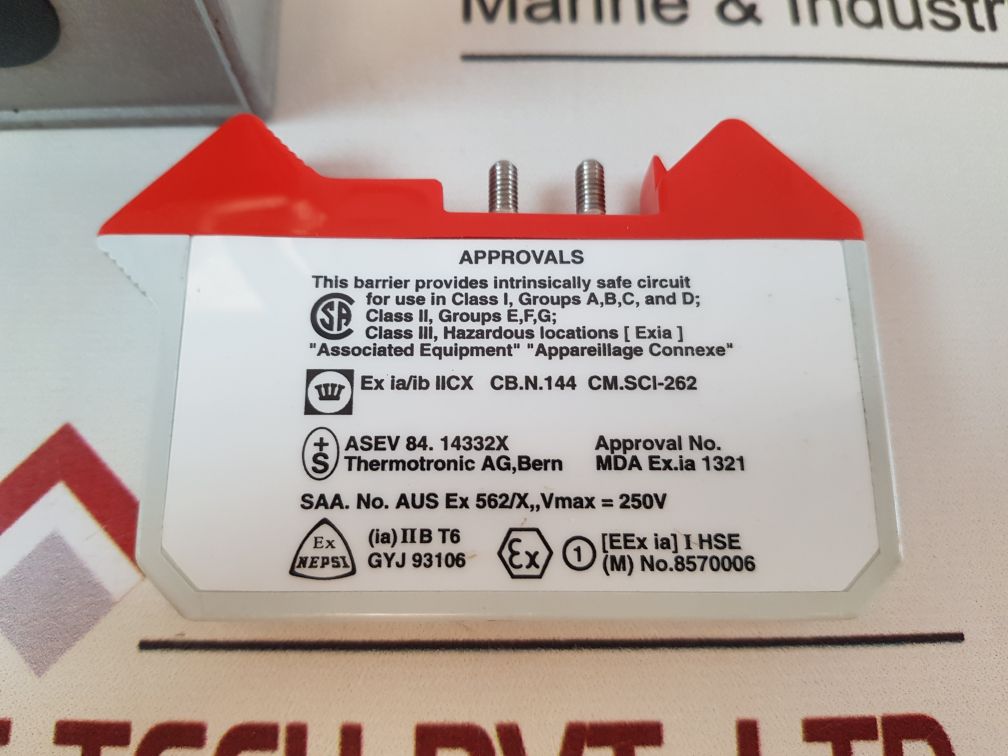

| Certification | [EEX IA] IIC 250UM 28UZ 28UZ BASEEFA NO. EX 832452 |

| Classification | CL.I, DIV. 1, GPS A,B,C,D; CL.II, DIV.1, GPS E,G; CL.III, DIV.1 DWG SCI-88 |

| Electrical Ratings | VOC 29.37V, ISC 93MA, CA 0.11µF LA 4.0MH VM 250V R.M.S. |

| Origin | MADE IN ENGLAND |

| Weight | 430 GM |

| Condition | NEW 2 PCS |

| Reference Number | 53730 |

Understanding the Shunt-Diode Safety Barrier

A shunt-diode safety barrier is a crucial device used to limit the electrical energy from reaching dangerous levels of voltage and current in hazardous areas. This is done by restricting the voltage and current that can go into them. When the intrinsically safe equipment is in relation to it, then it helps act as a critical barrier for the risk of explosion caused by electrical faults.

The MTL 779+ is an advanced model that builds on this concept, offering enhanced performance and reliability. Its robust design and adherence to international safety standards make it a preferred choice across industries.

Key Features of the MTL 779+

High Reliability: The MTL 779+ ensures dependable performance even in the most challenging conditions. Its rugged construction and meticulous engineering minimize the risk of failure.

Wide Compatibility: MTL 779+ is designed to integrate well with a range of intrinsically safe systems and thus simplifies implementation without losing on safety.

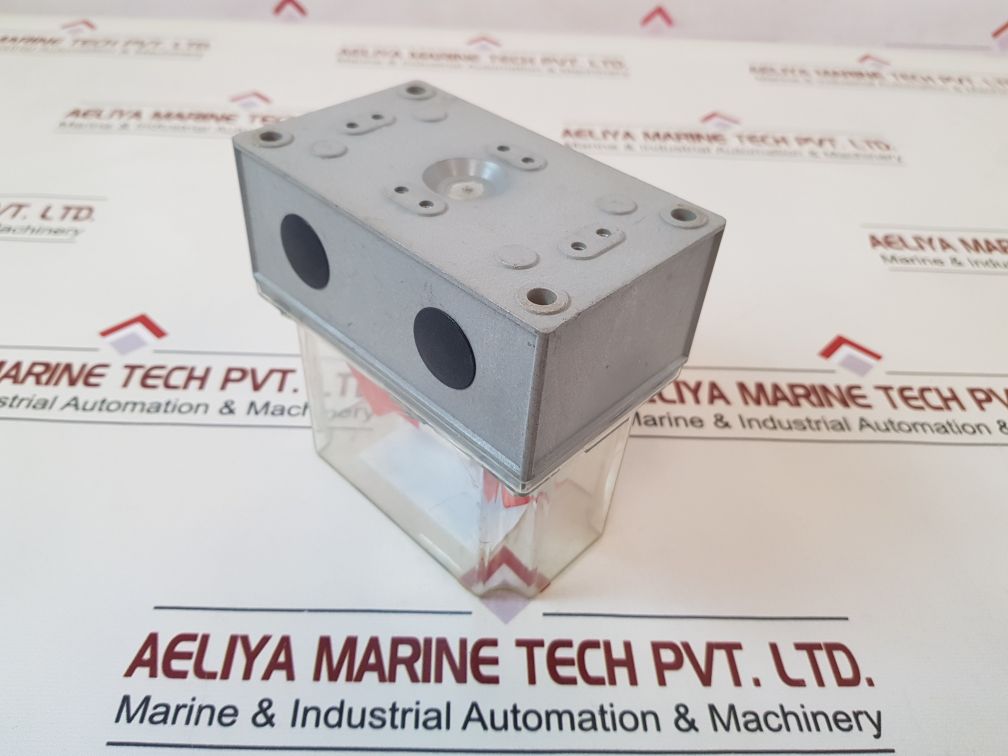

Compact Design: With space always at a premium in industrial installations, the MTL 779+ offers a compact form factor without losing out on functionality.

Compliance to Standards: MTL 779+ meets the global safety standards and comes with ATEX and IECEx certifications that guarantee effectiveness in hazardous locations.

Low Maintenance: With a strong durable design, MTL 779+ has minimum maintenance needs to ensure reduced time and costs spent on downtime operations.

Applications of the MTL 779+

The versatility of the MTL 779+ makes it apt for various applications in the following:

Oil and Gas Industry: Protecting the equipment of sensors and transmitters within explosive environments.

Chemical Processing: Protecting facilities that handle volatile materials.

Pharmaceutical Manufacturing: Protect equipment in facilities dealing with volatile chemicals.

Mining Operations: Gas Hazardous Areas Electrical systems are protected in underground areas where gas hazards can prevail.

Benefits of Utilizing MTL 779+

Improved Safety: It prevents igniting fires in hazardous zones by limiting energy transfer.

Cost-Effective Solution: Economically Viable Option Its durability and low maintenance ensure that industries save in the long term.

Easy Installation: Process Its simple design and compatibility with other systems facilitate easy installation.

Global Acceptance: With international recognition of certificates, the MTL 779+ is always a trusted offer for transnational operations.