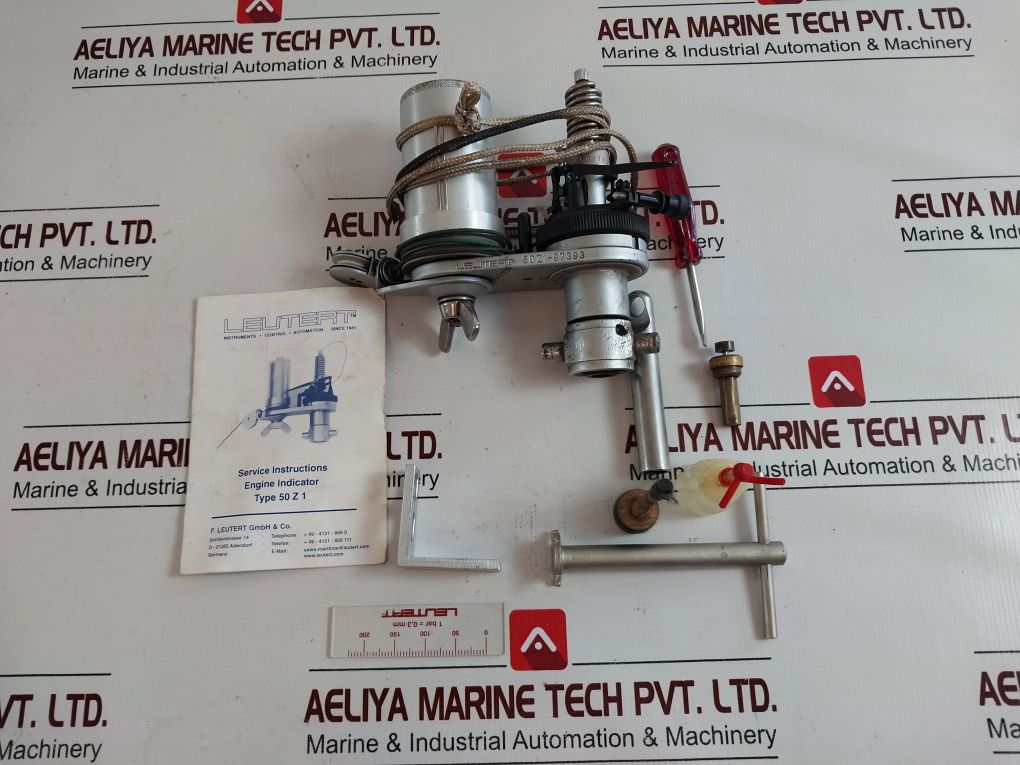

Leutert 50z1-97393 Engine Indicator

F.leutert Gmbh & Co.

Instruments Control Automation

Engine Indicator

Type 50 Z 1

50z1-97393

50/16 Bar

1 Bar=0,3 Mm

Germany

Weight : 4.210 Kg

Ref No(S) : 64900

What is the Leutert 50z1-97393 Engine Indicator?

The Leutert 50z1-97393 is a highly technologically advanced engine indicator designed to be exclusively for use in diesel engines on the seas and industrially. Leutert is a German-based company renown for its remarkably accurate measuring tools. This engine indicator is engineered to deliver accurate pressure readings on diesel engines’ combustion chambers.

The 50z1-97393 finds its use in maritime industries, with large cargo ships, oil tankers, and cruise liners, and in any industrial sectors that utilize stationary diesel engines for power generation.

Features of the Leutert 50z1-97393 Engine Indicator

Accurate Measurement:

The Leutert 50z1-97393 is valued for high accuracy in pressure changes. Highly detailed readings can be observed about the engine’s combustion chamber pressure variability. This is one reason why adjusting engine parameters to improve performance or perform corrective measures requires such accuracy.

Durability: For each difficult situation in which a superdiesel operates, there is Leutert 50z1-97393-designed for resistance to temperatures, pressure, and vibration for a long time of operating failure-free in very severe conditions.

Ease of Use: The Leutert 50z1-97393 is also user friendly, making it very easy for technicians to get up and running, to take readings. It is installed with intuitive interfaces and options for calibration that ensure users get all the data they need without having to jump through hoops in learning.

Versatility: This engine indicator can be applied to various types of diesel engines and is, therefore, applicable to a broad scope of applications. Be it a two-stroke or a four-stroke engine, the 50z1-97393 ensures reliable readings.

Industry Standards Compliance:

The Leutert 50z1-97393 follows highly advanced industrial standards to ensure that all readings presented are not only accurate but also dimensional in conformity with international standards. This makes it an ideal tool for companies seeking compliance with regulatory requirements on engine monitoring and emissions control.

Why the Leutert 50z1-97393?

1. Reliability under Harsh Conditions

Marine conditions are quite demanding on diesel engines. The Leutert 50z1-97393 is made to work perfectly even under very high temperatures, vibrational conditions, and drastic temperature changes. Whether you are in the cargo vessel’s engine room or monitoring a diesel generator in a power plant, you never go wrong with the durability of the indicator.

2. Concrete Evaluation of Engine Performance

The more suitable combustion of a diesel engine would be, the more efficiency it yields and reduces the emission. The high-precision pressure reading capability of this 50z1-97393 would allow one to make fine-tuning in the fuel injection and adjust air intake as well as the timing so that they can make the best out of their machines.

3. Cost Savings

The Leutert 50z1-97393 can give proper insights into the diesel engine’s performance. Prior to when a condition becomes critical and ends up in breakdown, it will diagnose such conditions. This will help avoid costly breakdowns or prolong the engine life. It diminishes the fuel consumption due to the performance optimization, which reaps enormous cost saving over time.

4. Regulation Compliance

The more the different regulations issued in various nations with regards to emissions and other environmental standards, the more critical accurate measurements of an engine become. The Leutert 50z1-97393 has an important role to play in ensuring the equipment meets the set standards by the company, avoiding fines and keeping each engine up to par with the demands of the international environmental forces, such as the IMO requirements.

How Does the Leutert 50z1-97393 Function?

The Leutert 50z1-97393 works when it is connected with the cylinder of an engine to measure changes in pressure of combustion. It is mostly used when an engine is under the process of maintenance or assessing its performance.

This is how the process is normally carried out in a normal case scenario:

Installation:

The indicator gets mounted on the indicator valve of the cylinder of the engine. It remains stuck during the combustion cycle.

Measurement:

During running, the indicator measures the pressure experienced in the cylinder. The data records peak pressures as well as changes that occur during the engine cycle.

Data Analysis

The data is recorded either manually or digitally depending on the type of setup. Pressure readings recorded can thus be used for analysis about the performance of the engine.

Adjustments:

From the readings, one can be able to tell what level of adjustment will suit the engine- whether changing the fuel-to-air ratio or simply just adjusting the timing between the fuel injectors and the spark plugs.