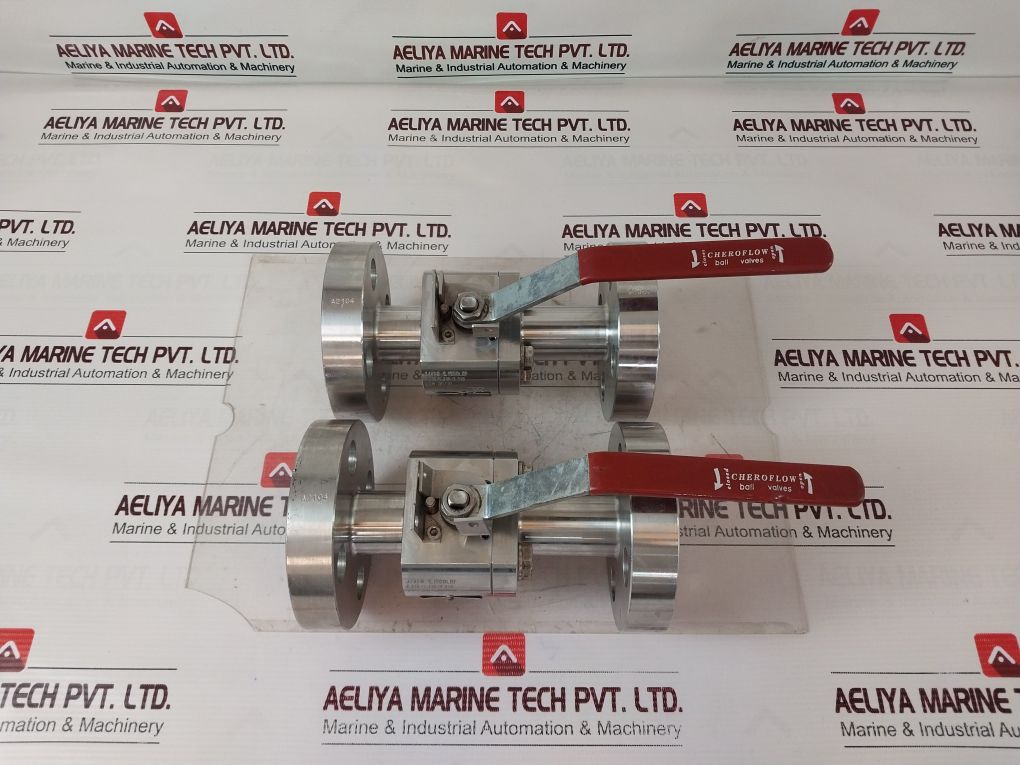

| Product | LCM Italia DN 3/4″ Ball Valve |

|---|---|

| Manufacturer | LCM Italia |

| Brand | Cheroflow |

| Type | Ball Valves |

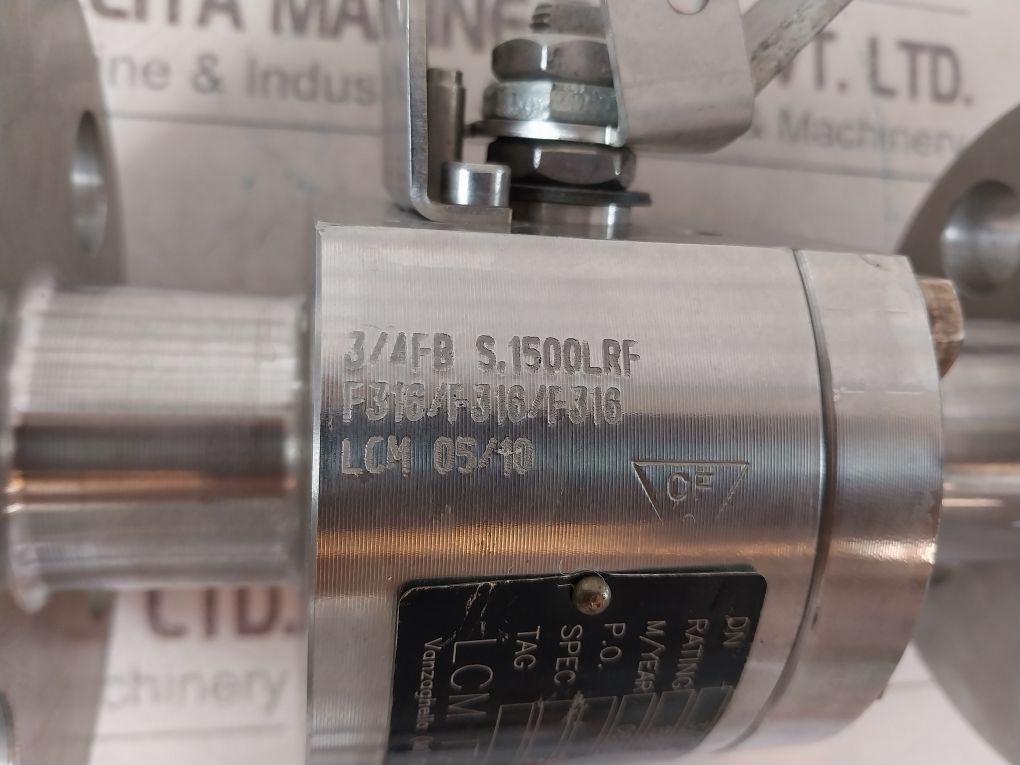

| Size | DN 3/4″ |

| Pressure Rating | 1500 |

| Maximum Operating Pressure (M.O.P.) | 202 @ -46°C / 165 @ 120°C |

| Standard | ISO 14313 |

| Material | Body/Ball/Stem: F316L |

| Seat Material | Devlon |

| Model | 220 |

| Item | Item 1 |

| Certification | II 2Gcx |

| Technical File | AX0107 |

| Code | 3/4FB S.1500LRF |

| Material Code | F316/F316/F316 |

| Manufacturer Code | LCM 05/10 |

| Serial Number | A2104 |

| Origin | Italy |

| Weight | 8.900 Kg |

| Ref No | 71613 |

What is the LCM Italia DN 3/4″ Ball Valve?

LCM Italia DN 3/4″ Ball Valve The LCM Italia DN 3/4″ Ball Valve is a manual shut-off valve that is used to control liquids and gases in a pipeline. The diameter is 3/4″ (DN 20), so it is perfect for medium-sized fluid lines. It has the form of a rotating ball which has a hole right through the center and can be put into positions which either permit or block flow: hence, simple on/off functionality.

The manufacturer, LCM Italia, has gained recognition for rigorous industrial valve production standards. Therefore, this ball valve meets severe performance requirements with a probable warranty of hassle-free operation and a long service life.

Key Features and Benefits

Robust Building: The LCM Italia DN 3/4″ Ball Valve is made up of top quality materials, stainless steel and brass, more specifically created in order to ensure that the product will have remarkable resistance against anticorrosion, wear and temperature. It means that it can be reliable for a long time in different kinds of industrial conditions.

Full Bore Design: The valve is full bore, hence ruling out any pressure drop and making it useful where the provision of adequate fluid flow rate is necessary at all times.

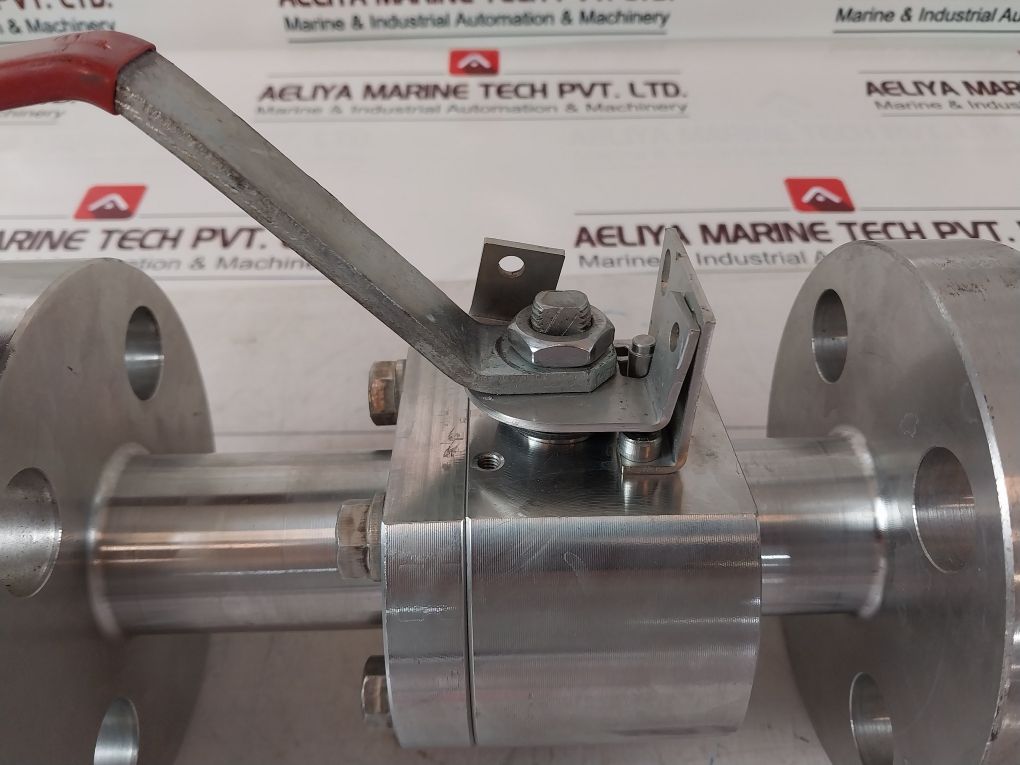

Easy Operation: The manual handwheel with an easy rotating valve permits fast and free control of fluid flow. A 90-degree turn can be made for either opening or closing the valve, and positive response is always provided in potentially dangerous situations.

Leak-Tight Seal: The LCM Italia DN 3/4″ Ball Valve features precision-designed seals for a leak-tight shut-off, and fluids cannot seep through it. This way, at any high pressure, it remains safe to operate.

Versatility: The ball valve is suitable for water, oil, gas, and many chemicals. It could be used with a wide variety of applications related to manufacturing, marine applications, chemical processing, and HVAC systems.

Applications of LCM Italia DN 3/4″ Ball Valve

The LCM Italia DN 3/4″ Ball Valve could be applied to diverse industrial fields and applications. These are some of the most frequent use cases of it as follows:

Water and Wastewater Treatment: In treatment plants, such water treatment process needs proper valves to control water flow. The LCM Italia ball valve has the ability to perfectly control during the operation and maintenance operations.

Oil and Gas Industry: This valve can be used for the control of flow in oil and gas handling pipelines, storage tanks, and process equipment. It uses strong construction and leak-tight sealing.

Marine Sector: The LCM Italia DN 3/4\\\” Ball Valve is useful for marine applications since it’s quite well suited for the most critical environments to ensure high resistance to corrosion, like seawater, fuel, or hydraulic fluids.

Heating, ventilation, and air conditioning: HVAC; Valve application for water flow regulation for heating circuits or isolation valve in cooling towers.

Why Choose the LCM Italia DN 3/4\” Ball Valve?

The LCM Italia DN 3/4 Ball Valve, therefore, is best suited for the use of a ball valve in the control of fluids with reliability, effectiveness and simplicity of operation, making it an excellent fit for many industrial applications whether used as a standalone unit or as an integral part of a greater system. In addition to this class of usefulness, its durability and full bore design put it on a pedestal that cannot be easily replaced with ease and flexibility. It also offers many other benefits to its user that are sure to save one time and money in the long run, such as a minimized need for maintenance, its design lending itself to easy operation.

Reviews

There are no reviews yet.