| Attribute | Value |

|---|---|

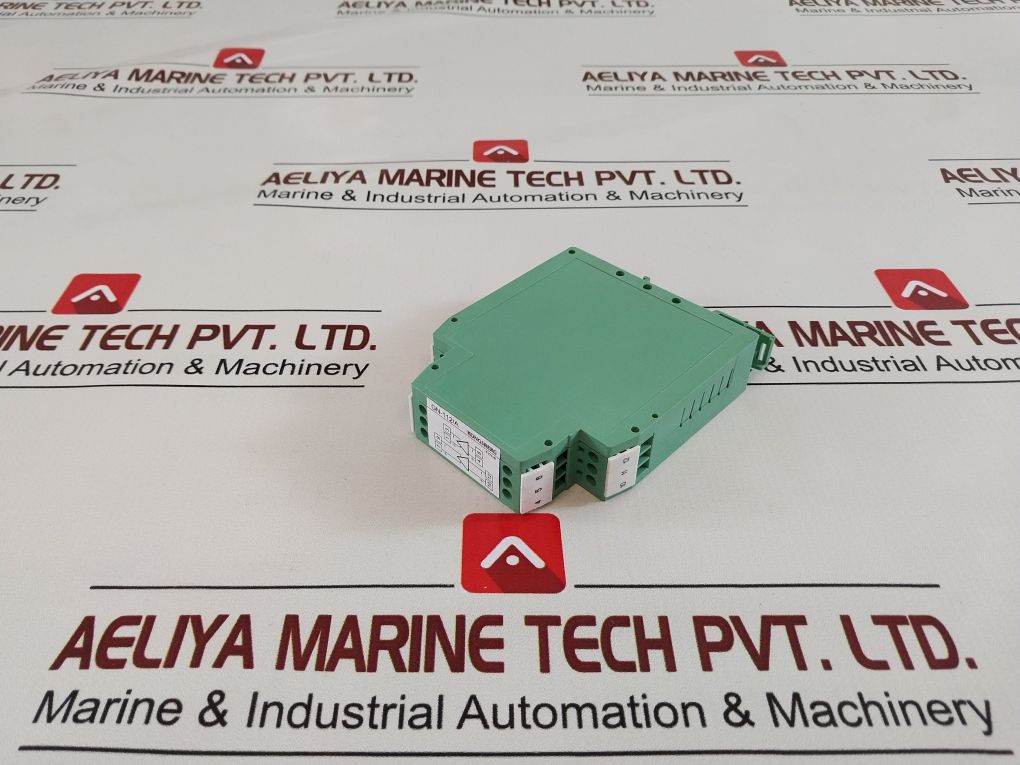

| Brand | Kongsberg / Phoenix Contact |

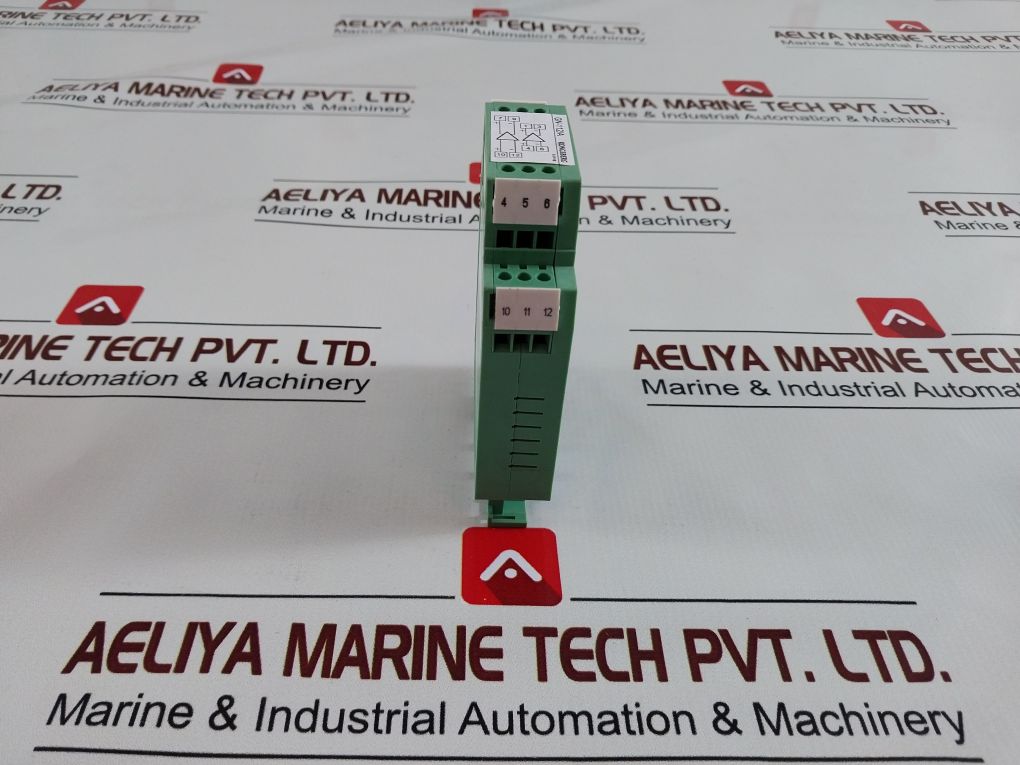

| Type | GN-112/A |

| Function | Dual Thermocouple Amplifier |

| Measuring Range | 0–600°C |

| Input | Thermocouple NiCr-NiAl |

| Output | 4–20mA, Two Wire |

| Power Supply | 12–35 VDC |

| Model Numbers | E-2741/2, E-2741/1, SW 170, UEGH |

| Weight | 120 gm |

| Condition | New – 1 Piece |

| Reference No. | 58879 |

What Is a Dual Thermocouple Amplifier?

A thermocouple amplifier plays the crucial role of amplifying and conditioning thermocouple signals—sensors that quantify temperature from differences in voltage across two different metals. The dual version of the GN-112/A enables it to process two independent thermocouple inputs, making it perfectly suited for multi-point temperature sensing in a space-saving package.

The GN-112/A is produced by Phoenix Contact, a world-renowned automation technology brand, and is usually distributed by industrial automation firms such as Kongsberg, which specializes in incorporating high-performance components in mission-critical systems.

Features of the Kongsberg GN-112/A:

Dual Input Channels – Accommodates two thermocouple inputs for parallel monitoring.

High Accuracy – Provides accurate readings even in changing industrial environments.

Signal Conditioning – Internal filtering and linearization for purer output signals.

Compatibility – Compatible with general thermocouple types such as J, K, and T.

DIN Rail Mounting – Simple integration with control panels and enclosures.

Galvanic Isolation – Signal interference protection between channels.

LED Indicators – Visible indication of power status and signal presence.

Compact Design – Space-efficient module perfect for dense cabinet installations.

Wide Voltage Range – Functions effectively under diverse power supply scenarios.

Long Operational Life – Designed to withstand harsh industrial conditions.

Applications in Industrial Environments

The GN-112/A amplifier has widespread application in industries requiring thermal accuracy. Following are typical applications where it is particularly useful:

Marine Automation Systems – For engine room temperature monitoring and safe propulsion system running.

Industrial Ovens & Furnaces – Regulates and sustains uniform temperature levels for production.

Power Plants – Monitors boiler or turbine temperatures for maximum efficiency and safety.

Oil and Gas Processing – Tracks essential temperatures in pipelines and refining operations.

Pharmaceutical Manufacturing – Provides sterile environments with accurate environmental control.

HVAC Control Systems – Reduces energy consumption through heating and cooling control.

Automotive Testing – Monitors engine and exhaust temperatures during test conditions.

Food and Beverage Industry – Keeps temperatures during processing and packaging as needed.

Plastic Molding Operations – Assists in keeping mold temperature levels consistent for product quality.

Aerospace Ground Testing – Utilized in high-accuracy applications to track component temperature.

Why Select the GN-112/A?

The GN-112/A is unique in that it offers engineering-grade accuracy, flexible configuration, and field-tested performance. It’s purpose-built to address demanding industrial uses and remain accessible to technicians and system integrators. Its dual-channel design minimizes hardware space and installation overhead—something to appreciate when space and efficiency are concerns.