IMI MAXSEAL Y013AA1H1BS STAINLESS STEEL SOLENOID VALVE

IMI PRECISION

THOMPSON VALVES

MAXSEAL

ICO3S

DUAL-SEAL

MAXSEAL PART NO: Y013AA1H1BS

WORKING PRESSURE/ W/P: 0-12 BAR

NOMINAL DIA/BORE: 6MM

CLASS I, DIV 1, GROUPS BCD

CLASS I, ZONE 1, AEX D IIC

ZONE 1, EX D IIC

IECEX CML 16.0034X

CML 16ATEX 1075X

II2 GD

LR1380-2 | CRN 0C08155.2

DUAL SEAL | TYPE 4X | IP66/X

EX DB IIC

T6 TA -55°C TO +50°C GB

T4 TA -55°C TO +90°C GB

EX TB IIIC T130°C DB

24 V 3.0W DC HZ

67521095

SCH171811

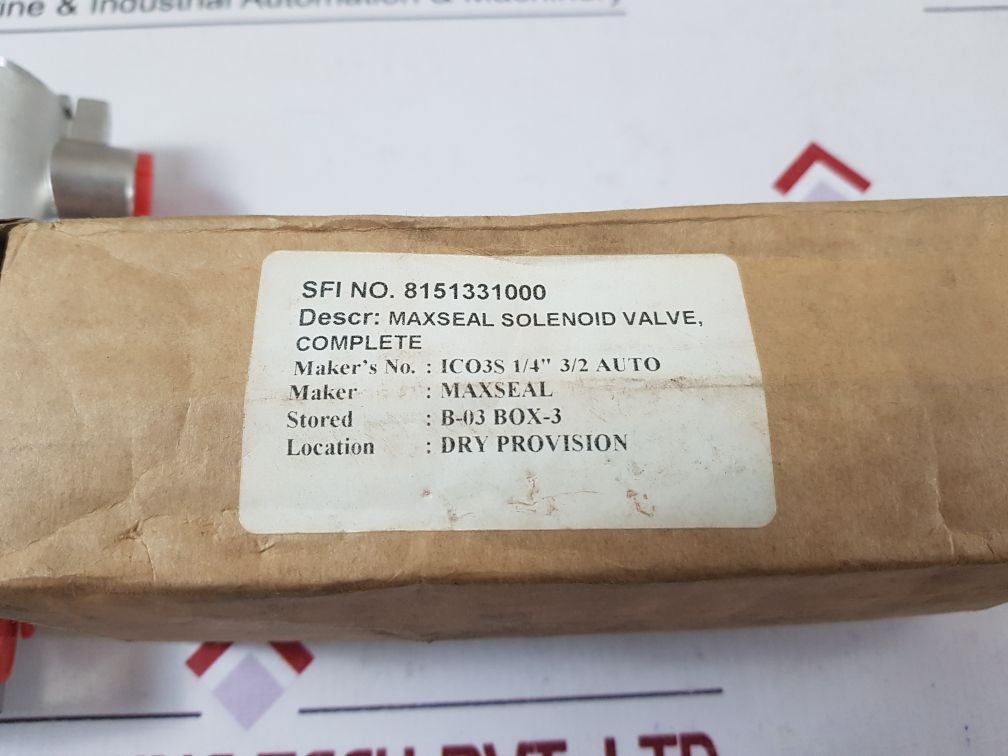

SFI NO. 8151331000

DESCR: MAXSEAL SOLENOID VALVE,COMPLETE

MAKER’S NO. : ICO3S 1/4” 3/2 AUTO

MAKER: MAXSEAL

ENGLAND

WEIGHT : 2.180 KG

REF NO(S) : 43186

Introducing the IMI MAXSEAL Y013AA1H1BS Stainless Steel Solenoid Valve – a precision-engineered valve designed to provide accurate control over fluid flow in demanding industrial environments. In this comprehensive guide, we will explore the inner workings of this exceptional product, its functions, ideal applications, and the numerous benefits it brings to your fluid control systems.

How Does the Product Work?

The IMI MAXSEAL Y013AA1H1BS Solenoid Valve operates based on electromagnetic principles to control the flow of fluids. Within its robust stainless steel body lies an intricate internal mechanism. When an electrical current is applied to the solenoid coil, it generates a magnetic field that moves the valve’s internal components. This movement either allows or blocks the flow of fluids through the valve, providing precise and reliable control.

This solenoid valve features dual seals, ensuring exceptional sealing performance and suitability for a wide range of applications.

When Should Someone Use the Product?

The IMI MAXSEAL Y013AA1H1BS Solenoid Valve is an indispensable component in situations where precise control over fluid flow is essential. Consider using this product when you need to:

- Control Fluids: Implement this valve to regulate the flow of liquids or gases in various industrial processes, ensuring accuracy and reliability in fluid control.

- Ensure Safety: Use it in applications where safety is of utmost importance, as it is designed to meet hazardous area classifications such as Class I, Div 1 and Zone 1.

- Operate in Challenging Environments: Utilize it in environments characterized by extreme temperature ranges, as it can function efficiently in temperatures ranging from -55°C to +90°C.

Where Should Someone Use the Product?

The IMI MAXSEAL Y013AA1H1BS Solenoid Valve is versatile and can be effectively employed in various applications and industries, including:

- Chemical Processing: Install it in chemical plants to control the flow of corrosive fluids securely and reliably.

- Oil and Gas: Use it in the oil and gas industry to regulate the flow of gases and liquids in hazardous environments.

- Manufacturing: Integrate it into manufacturing processes that require precise fluid control and automation.

How to Use the Product

Utilizing the IMI MAXSEAL Y013AA1H1BS Solenoid Valve is straightforward:

- Installation: Securely mount the valve within the fluid system, ensuring proper alignment with the direction of fluid flow.

- Electrical Connections: Connect the solenoid valve to a compatible electrical power source, typically 24V DC in this case.

- Control: Activate the solenoid valve by applying electrical current to the solenoid coil. This action will either open or close the valve, allowing or stopping the flow of fluids accordingly.

Specifications and Features

- Stainless steel construction ensures durability and resistance to corrosion.

- Precise fluid flow control for accurate automation and operation.

- Dual seals provide exceptional sealing performance for increased reliability.

- Hazardous area certifications make it suitable for use in challenging environments.

- Wide temperature range allows operation in extreme conditions.

Benefits

- Ensures accurate and reliable control over fluid flow.

- Provides safety in hazardous areas with its certifications.

- Operates effectively in extreme temperature environments.

- Corrosion-resistant stainless steel construction ensures durability.

- Versatile application across various industrial settings.