| Attribute | Value |

|---|---|

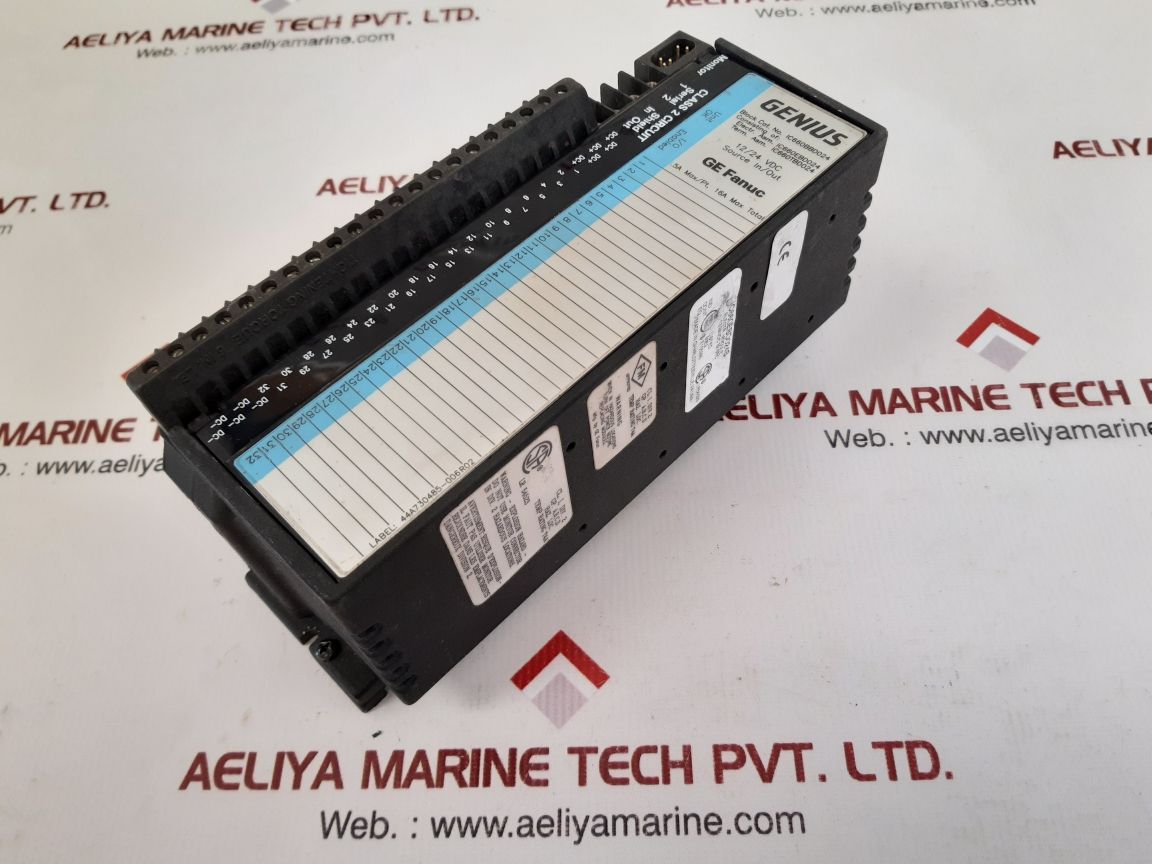

| Product Name | Ge Fanuc Ic660Bbd024S Genius I/O Control Module |

| Category | Genius |

| Block Cat.No. | Ic660Bbd024 |

| Consisting Of | Electr. Asm. Ic660Ebd024, Term.Asm. Ic660Tbd024 |

| Voltage | 12/24 Vdc |

| Source In/Out | .5A Max/Pt, 16A Max Total |

| Class | Class 2 Circuit |

| Label | 44A730485-006R02 |

| Term. Asm. Part Number | Ic660Tbd024K |

| Term. Asm. Voltage | 12-24Vdc 32 Src |

| Product ID | 4118373 |

| Electr. Module Part Number | Ic660Ebd024S |

| Electr. Module Voltage | 12-24Vdc 32 Src |

| Classification | Cl.1, Div.2, Gp.A,B,C,D |

| Temperature Rating | T4A |

| Manufacture Location | Made In Charlottesville, VA, USA |

| Weight | 1.440 Kg |

Specifications :

- Intelligent module with integrated diagnostics

- 24 discrete I/O points

- Built for rugged environments

- Hot-swap enabled design

- Plug-and-play interface with GE Genius Bus

Whether you are replacing a current system or constructing a new one from the ground up, both the IC660BBD024S and IC660TBD024K provide reliable performance.

Features of GE Fanuc IC660BBD024S

1. Distributed Control Capability

This I/O module allows for communication among multiple controllers and remote devices through GE’s Genius Bus, saving cabling expense and enhancing scalability.

2. Improved Diagnostics

Every module has built-in diagnostic functions that assist in identifying errors such as short circuits, open wiring, and configuration inconsistencies—reducing downtime.

3. Durable Industrial Design

Designed to function in harsh conditions, the IC660BBD024S is vibration-resistant, dust-tight, and can withstand extreme temperatures, so it is ideal for applications in marine, oil & gas, and factory automation systems.

4. Simple Configuration

With simple setup tools and auto-recognition capabilities, engineers are able to incorporate this module in PLC and DCS systems with little setup time.

Applications

The IC660BBD024S proves useful in a broad range of automation environments:

Manufacturing: Manages sensors, actuators, and motor drives on the factory floor.

Marine Systems: Works with navigation and engine management systems.

Oil & Gas: Processes signals in refineries and offshore rigs.

Water Treatment Plants: Controls flow meters, pumps, and level indicators.

Power Plants: Supports control logic for turbine and generator systems.