| Attribute | Value |

|---|---|

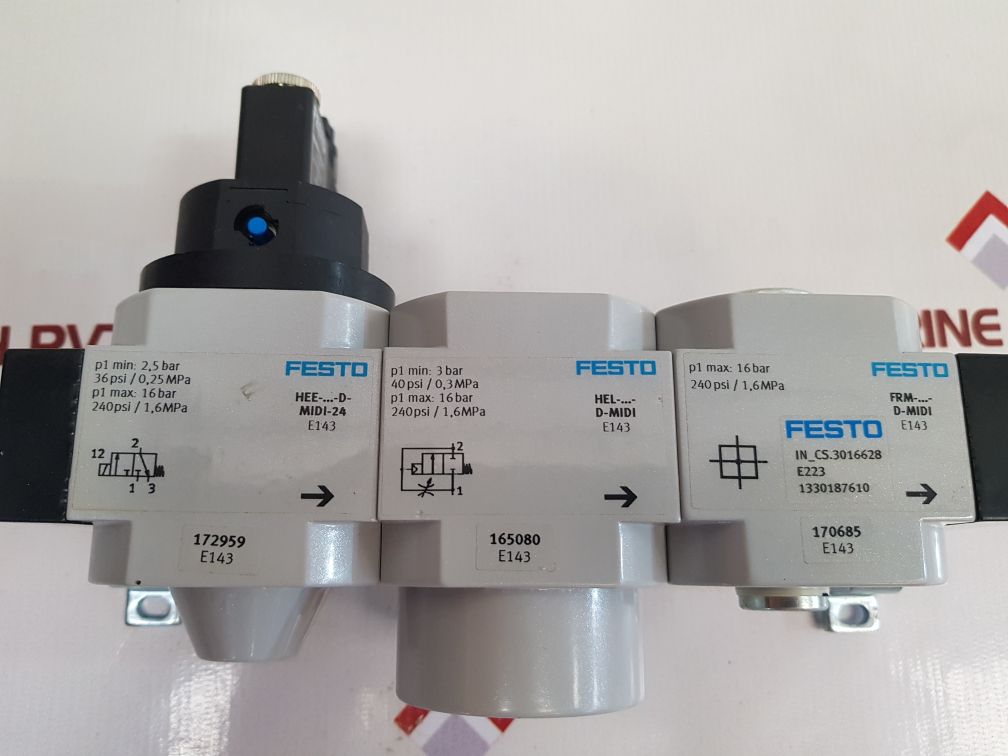

| FESTO HEE-…-D-MIDI-24 | Code: 172959 E143 P1 MIN: 2,5 BAR (36 PSI/0,25 MPA) P1 MAX: 16 BAR (240 PSI/1,6 MPA) |

| FESTO HEL-…-D-MIDI | Code: 165080 E143 P1 MIN: 3 BAR (40 PSI/0,3 MPA) P1 MAX: 16 BAR (240 PSI/1,6 MPA) |

| FESTO FRM-…-D-MIDI | Code: IN_CS.3016628 E223 1330187610 170685 E143 P1 MAX: 16 BAR (240 PSI/1,6 MPA) |

| MSEBB-3-24V DC | Code: 712 576 Voltage: 21.6-26.4VDC, 3W IP Rating: IP00/65 Weight: 1.370 KG Ref No: 37293 |

Understanding Your Festo Maintenance Unit

Before discussing maintenance, one needs to get familiar with the parts of the Festo Midi-24 E143 and D-midi E143 units. These normally comprise:

Filter Regulator: Eliminates moisture and particulates from the air.

Lubricator: Adds a predetermined amount of oil into the air stream to lubricate moving parts within pneumatic tools.

Pressure Gauges: Monitor the pressure levels within the system.

Routine Inspection and Maintenance

Visual Check: A general visual check over the entire assembly should be undertaken. Inspect the hoses and fittings for damage or signs of wear on the housing. Also, inspect whether all the fittings are securely attached.

Filter Maintenance: Filter element needs to be replaced regularly for avoiding blockages and air quality degradation. A filter change period can be accessed in the manufacturer’s instructions and some spares need to be in stock at the same time.

Lubricator Check: Ensure the lubricator has the proper oil level and consistency. It should be topped up with the recommended type of oil. One must use the right oil not to damage anything and to work effectively.

Monitoring Pressure Gauges: Check on the pressure gauges regularly. If there are sudden changes in pressure, this may indicate leakage or other pneumatic system issues.

Advanced Maintenance Tips

Leak Detection: At intervals, a soap solution around all connections can be used to detect leaks. The formation of bubbles indicates a leak and must be corrected right away.

Regulator Adjustment: Adjust the regulator as necessary to meet the pressure requirements of your tools and equipment. Incorrect pressure settings can result in inefficient operation and increased wear on pneumatic components.

Seasonal Adjustments: Take into account environmental factors such as temperature and humidity that may impact your Festo units’ performance. Modify your maintenance routine accordingly.