| Attribute | Value |

|---|---|

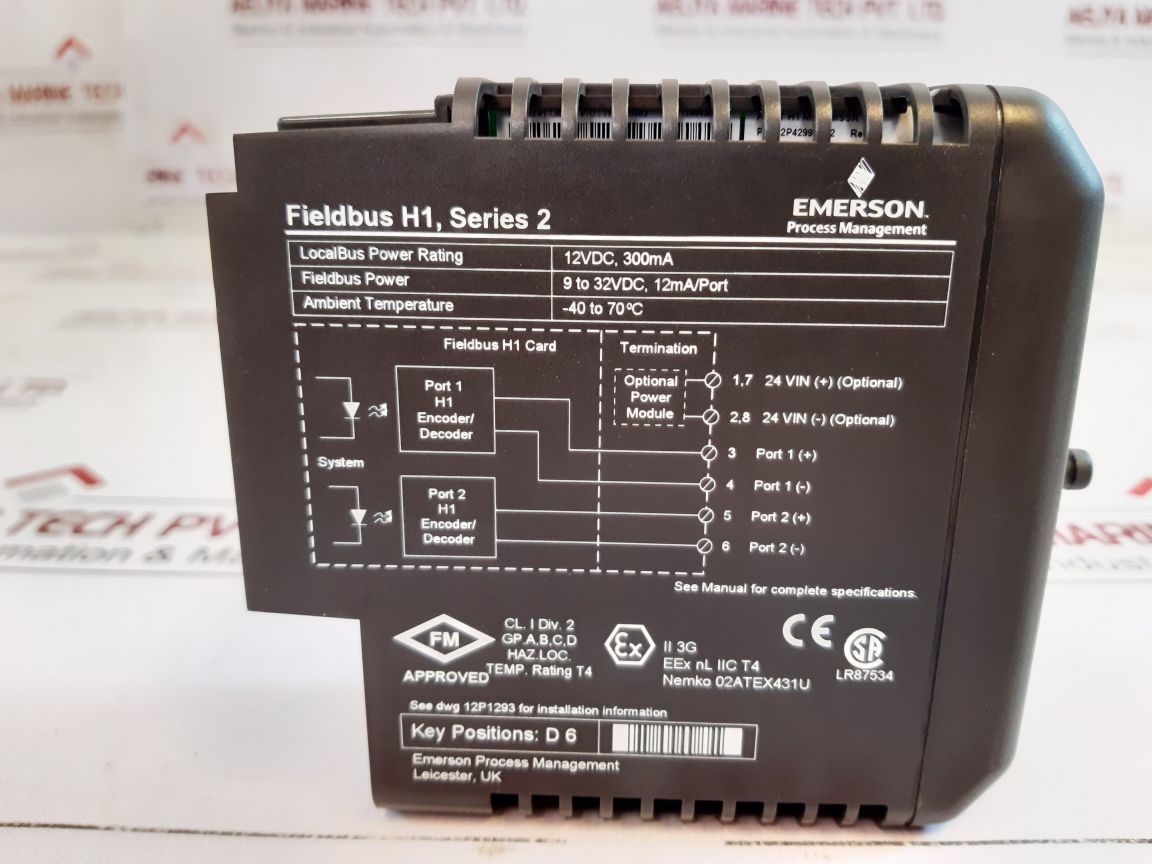

| Brand | Emerson Process Management |

| Manufacturer | Fisher-Rosemount Systems |

| Model | Deltav Fieldbus H1, Series 2 |

| Localbus Power Rating | 12VDC, 300mA |

| Fieldbus Power | 9 to 32VDC, 12mA/port |

| Ambient Temperature | -40 to 70°C |

| Hazardous Area Certification | Cl.I, Div.2 Gp. A, B, C, D |

| Temperature Rating | T4 |

| Ex Certification | II 3G, EEx nL IIC T4 |

| Certification Number | Nemko 02ATEX431U |

| Key Positions | D 6 |

| Part Number | KJ3242X1-BA1 |

| TMN | TMN019929 |

| PN | 12P2471X052 |

| Revision | F |

| Country of Origin | Made in Thailand |

| Weight | 200 gm |

| Condition | Used, 10 Pcs |

| Reference No | 56281 |

What is the Emerson DeltaV Fieldbus H1, Series 2?

The Fieldbus H1 Series 2 is a digital communication interface module used to link field instruments to the DeltaV DCS through the Foundation Fieldbus protocol. With its 31.25 kbps operation, the H1 Fieldbus segment supports two-way communication and device power over one pair of wires — significantly lowering wiring complexity and increasing efficiency.

Key Features:

- High-speed digital communication by Foundation Fieldbus H1 protocol.

- Series 2 reliability, providing hardware upgrade and extended lifecycle support.

- Less wiring cost with a single-cable solution for power as well as data.

- Better diagnostics that enhance visibility into field device performance and process conditions.

- Hot-swappable modules, with minimal downtime for maintenance.

Why Select Fieldbus in Place of Traditional I/O?

Fieldbus H1 is a better choice than traditional analog I/O systems because it can transmit rich diagnostic and status information in addition to control signals. With Fieldbus H1:

- Engineers are able to monitor and set up devices remotely from the control room.

- There is considerable less control cabinet space with fewer wiring terminals needed.

- Data accuracy is better, minimizing signal degradation typical of analog systems.

The Series 2 module complements these advantages further with increased processing power, firmware updates, and enhanced integration capabilities with DeltaV systems.

Applications of the DeltaV Fieldbus H1 Series 2

The DeltaV Fieldbus H1, Series 2 is applied across process industries such as:

Oil & Gas: Providing safe and reliable pressure, temperature, and flow sensor monitoring in hostile environments.

Pharmaceuticals: Offering accurate control of batching and formulation processes with traceable information.

Chemical Processing: Providing real-time process adjustments with minimal delay.

Power Generation: Optimizing turbine and boiler performance with integrated device control.

Due to its support for a broad spectrum of field devices, this module integrates easily into both legacy and modernized plant infrastructures.

Benefits of Utilizing Emerson DeltaV H1 Fieldbus Modules

Enhanced Operational Efficiency

Through digital communication, users have real-time visibility into system performance, allowing proactive maintenance and improved process decisions.

Scalability

Whether you are adding to a small system or integrating across an entire plant, Fieldbus H1 simplifies scaling your automation installation.

Integration-Ready

Compatible with DeltaV’s user-friendly engineering and operations software, making setup and training requirements low.

Lower Total Cost of Ownership

The minimized wiring, added reliability, and diagnostic features cut the need for repeated maintenance and troubleshooting.