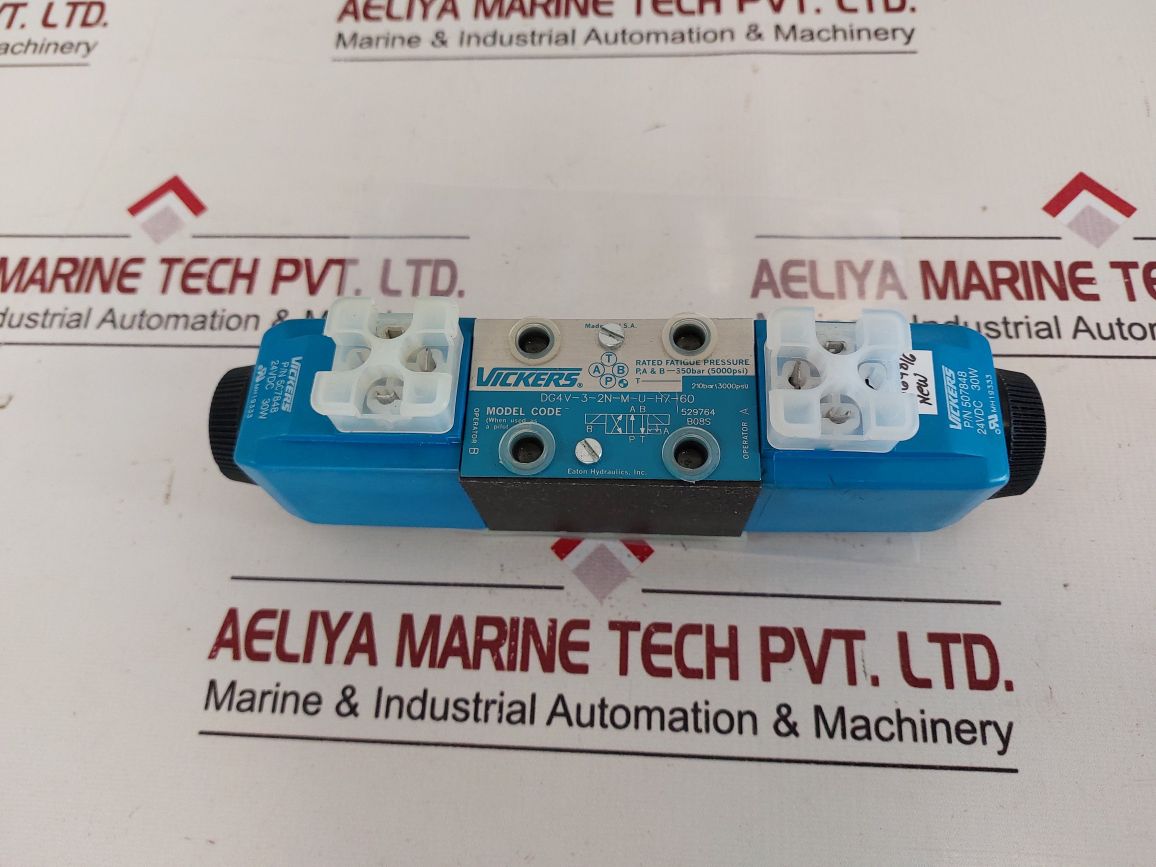

| Attribute | Value |

|---|---|

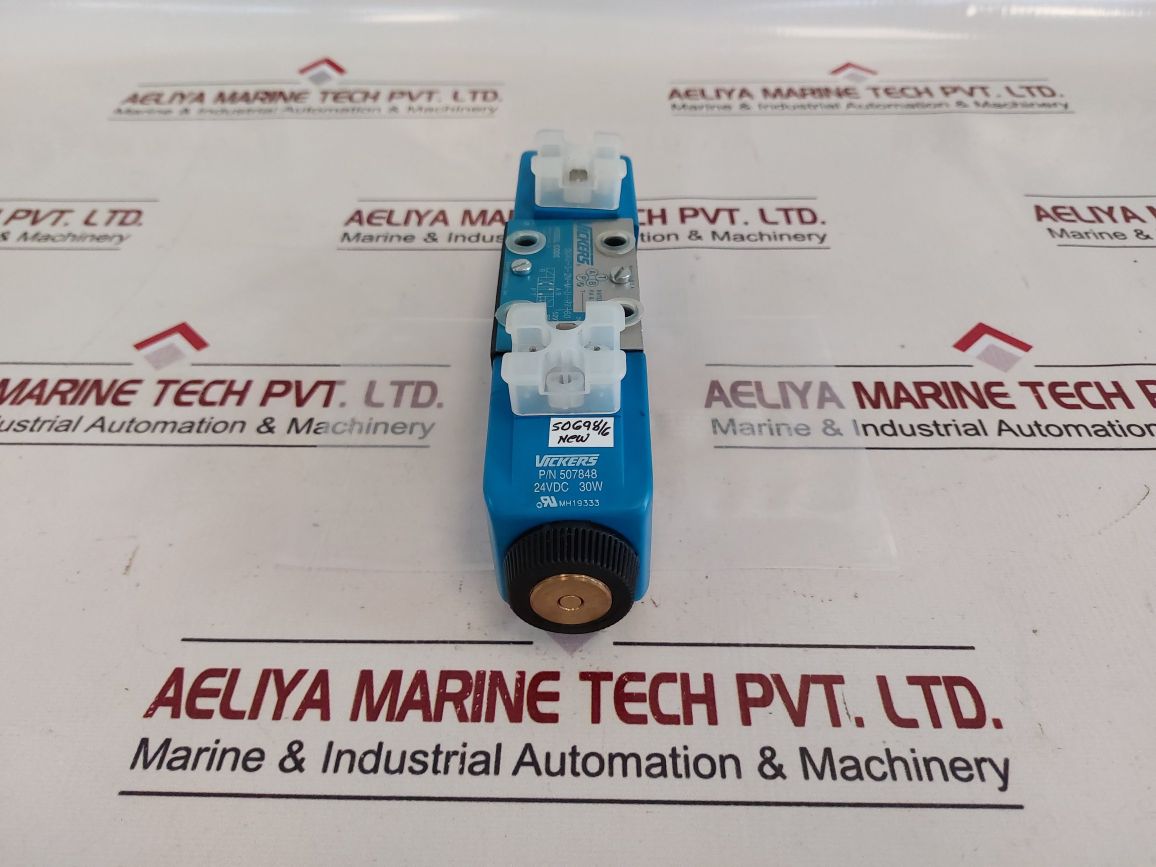

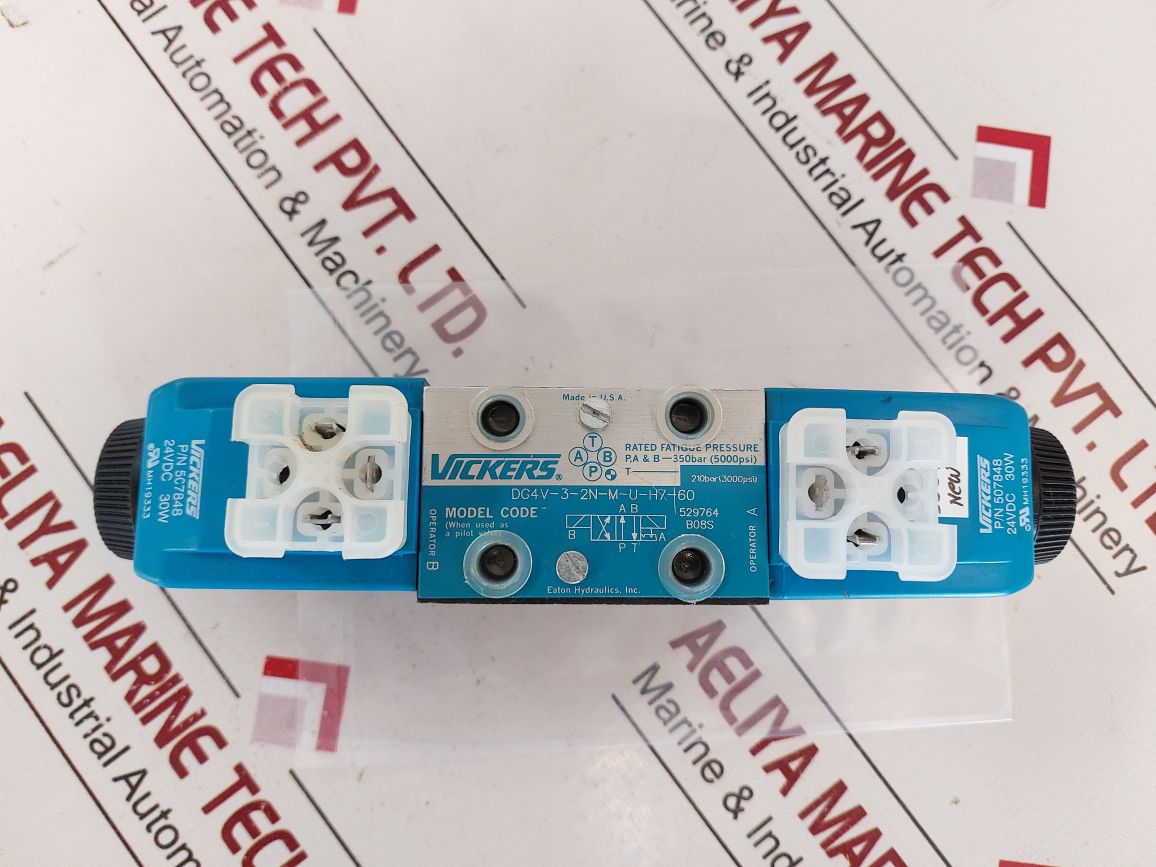

| Product Name | Eaton Vickers DG4V-3-2N-M-U-H7-60 Hydraulic Valve |

| Brand | Eaton Hydraulics, Inc. / Vickers |

| Model Code | DG4V-3-2N-M-U-H7-60 |

| Rated Fatigue Pressure | P, A & B: 350 Bar (5000 PSI) T: 210 Bar (3000 PSI) |

| Part Number | 507848 |

| Additional Code | 529764 / B08S / MH19333 |

| Voltage & Power | 24 VDC, 30W |

| Country of Origin | Made in U.S.A. |

| Weight | 2.200 kg |

| Reference Number(s) | 50698 |

What is a DG4V-3-2N-M-U-H?

The Eaton Vickers DG4V-3-2N-M-U-H7-60 Hydraulic Valve is an efficient solenoid operated directional control valve. This valve comes from the well-known Vickers DG4V range and has been developed to control the direction of fluid movements efficiently. As such, it can be used to control the operation of actuators like cylinders and motors.

Being a DG4V-3 series component, the DG4V-3 typically has a 4-way, 3-position mode, wherein the valve is capable of directing the fluid flow among various ports for the purpose of starting, stopping, and reversing the movement of the actuator. The solenoid actuation enables efficient electric control.

Main Characteristics of Eaton Vickers DG4V-3-

1. Solenoid-Actuated Direction

In this valve, control of hydraulic fluid direction is enabled using electrical solenoids, hence increasing accuracy and automation of hydraulic systems.

2. Design Performancia

The engine is designed to work under heavy conditions, with the DG4V-3-2N-M-U-H7-60 engine providing optimal performance for smooth gear shifts and long service cycles.

3. Industry-Standard

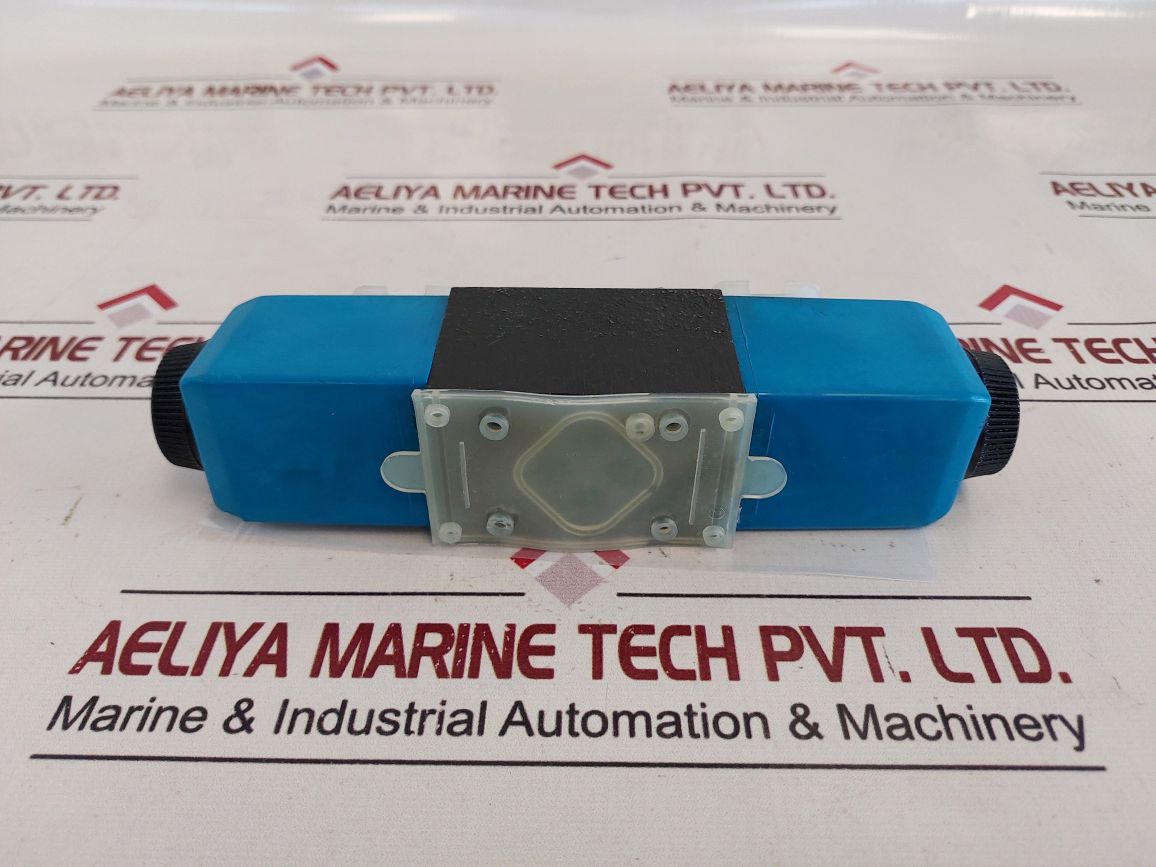

The interface for its mounting complies with ISO 4401 (size 03), ANSI/B93.7M-D03 specifications, allowing it to be compatible with the subplate/manifold available in

4. Excellent Flow and Pressure Ratings

• Max Flow: Up to 21 GPM (80 L/min)

• Pressure Rating: Up to 350 bar (5000 psi) depending on configuration

• Tank Port: 3000 psi

These ratings make it suitable for heavy-load operations.

5. Efficient Electrical Interface

Equipped with an ISO 4400 (DIN 43650) electrical connector, the valve allows straightforward wiring with standard industrial solenoid coils.

6. Durable Construction

Manufactured for rugged duty, the valve body withstands industrial pressures and environmental conditions, making it ideal for continuous use in machinery and automation systems.

Applications of DG4V-3-2N

Industrial Automation

Such valves are used to control fluid flow in automatic press machines, material handling systems, and industrial robots. They enable the fluid to act on the actuator.

Building & Heavy Equipment

It is used in excavators, loaders, cranes, as well as in similar equipment. Its job is to handle hydraulic cylinders and motors to provide smooth operations.

Marine Systems

In marine hydraulic systems like steering gear, winches, and deck machinery, such a valve can be trusted to control fluid direction based on load conditions and marine environment variables.

Manufacturing Machinery

Ranging from injection molding machine lines to conveyors, the DG4V-3 model is capable of accurate hydraulic control.

Mobile Hydraulic Platforms

Designed for vehicles and equipment requiring the use of hydraulic power for associated systems.

Why Choose Eaton Vickers DG4V-3-2N-M-U-H7-60 Hydraulic Valve?

Trusted Brand and Build Quality

Eaton Vickers has a long-standing reputation for manufacturing reliable hydraulic components. The DG4V series reflects this expertise with components built for long life and dependable operation.

Versatile Performance

With excellent flow capacity and pressure tolerance, this valve adapts across various applications from light industrial setups to heavy-duty marine or construction machinery.

Easy Integration

Standards-based mounting and electrical connections provide seamless integration into existing hydraulic systems, reducing downtime and retrofit costs.

Precise Control

Solenoid operation enables electronic control, which is essential for automated systems, programmable operations, and modern industrial workflows.

Wide Support and Replaceability

As part of the widely used DG4V family, components and spare parts are readily available globally, ensuring maintenance is straightforward and cost-effective.