| Attribute | Value |

|---|---|

| Brand | Dungs |

| IP Rating | IP54 |

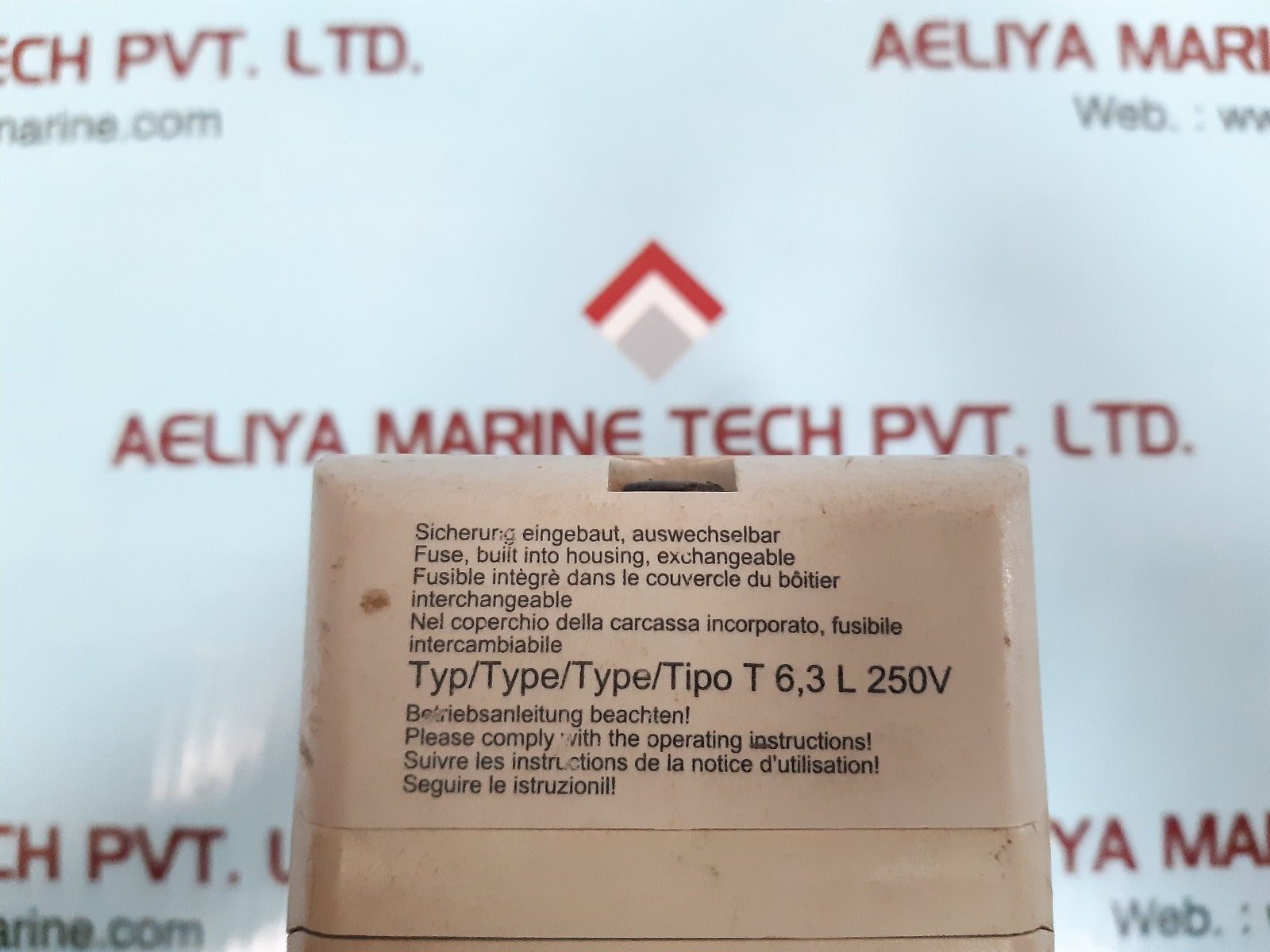

| Type | T 6,3 L 250V |

| Model | VPS 504 |

| Operation | Intern |

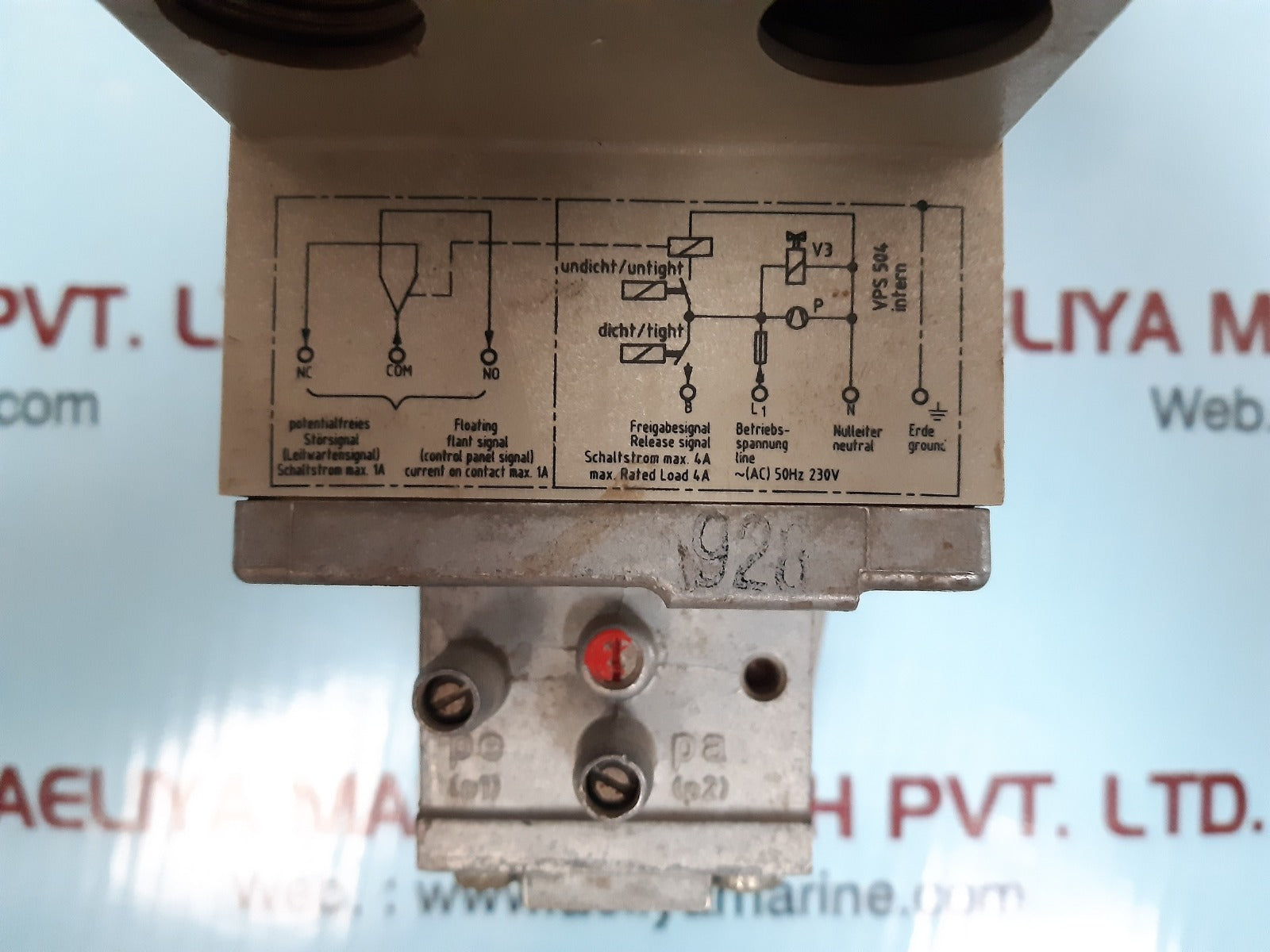

| Switching Current (Max) | 4A |

| Max Rated Load | 4A |

| Voltage & Frequency | ~(AC) 50Hz 230V |

| Country of Origin | Germany |

| Weight | 1.060kg |

Understanding the Dungs VPS 504 Valve Testing System

The VPS 504 is an electronic testing device that checks for leaks in gas shut-off valves. It works by testing the safety shut-off valves for integrity prior to burner ignition. The system shuts down the gas supply immediately if there is any leakage, thus preventing accidents and conforming to safety standards.

Important Features of the VPS 504:

Automatic Leak Detection – The system performs pre-ignition valve checks to verify gas-tightness.

Highly Reliable Sensor Technology – Accurately detects even slight gas leaks.

Fast Testing Cycle – Minimizes downtime and maximizes system efficiency.

Flexible Integration – Compatible with various gas valve types.

Compliance with Safety Standards – Compliant with EN 1643 and other global standards.

Advantages of Using the VPS 504 System

1. Improved Safety

The main role of the VPS 504 is to monitor gas leaks to avoid explosions and ensure the safety of workers. Through automatic shut-down in the event of a leak, it avoids risks caused by malfunctioning shut-off valves.

2. Compliance with Regulations

Industrial uses of gases are subject to rigorous safety standards. The VPS 504 complies with international safety standards to ensure that installations are up to the required guidelines without any complications.

3. Efficiency in Use

The quick test cycle minimizes system downtime, enabling smooth operations to carry on. With automated testing, manual intervention is not required, thereby conserving time and labor costs.

4. Cost Savings

Through the prevention of gas leaks and accidental events, the VPS 504 saves on maintenance and repair costs. It also prolongs the life of gas valves by keeping them in the best operating conditions.

5. User-Friendly Operation

The unit is easy to install and integrate into existing burner systems. It offers easy-to-understand diagnostic signals, so operators can easily recognize and solve problems quickly.